|

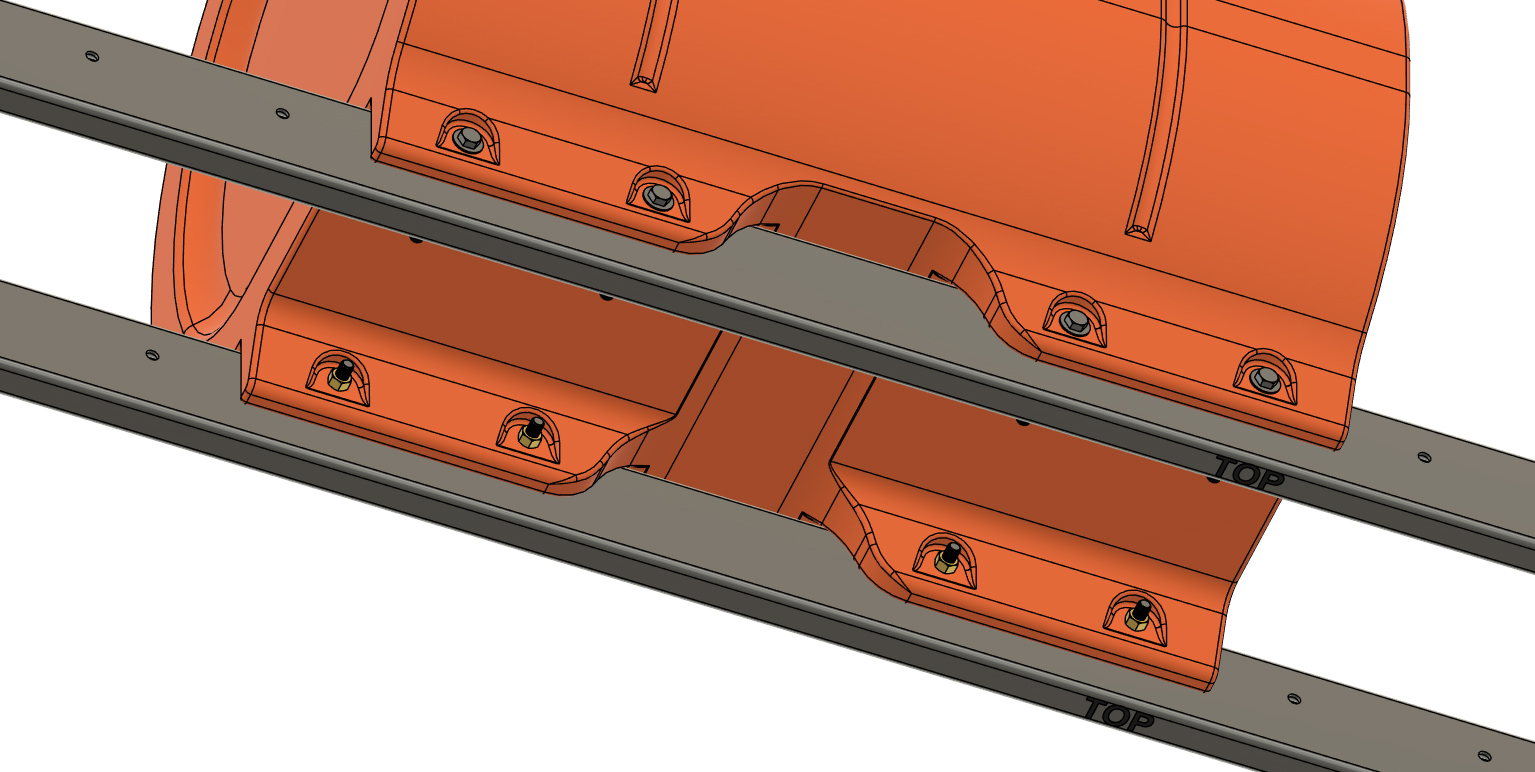

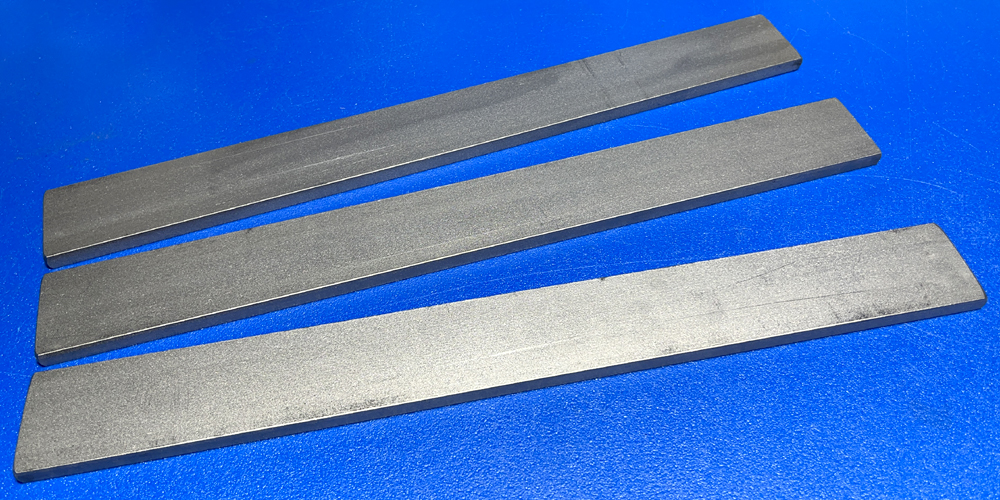

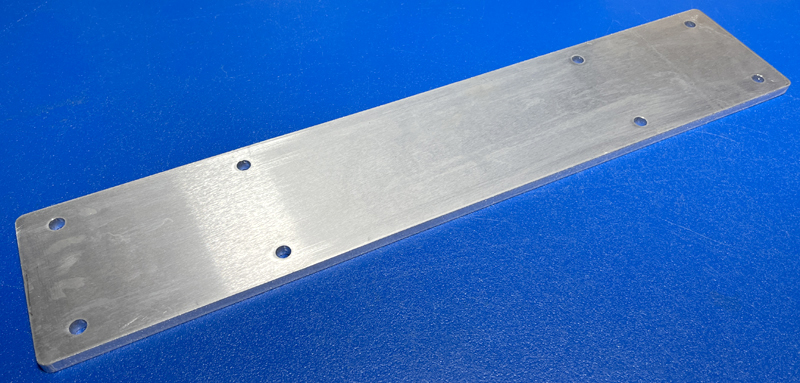

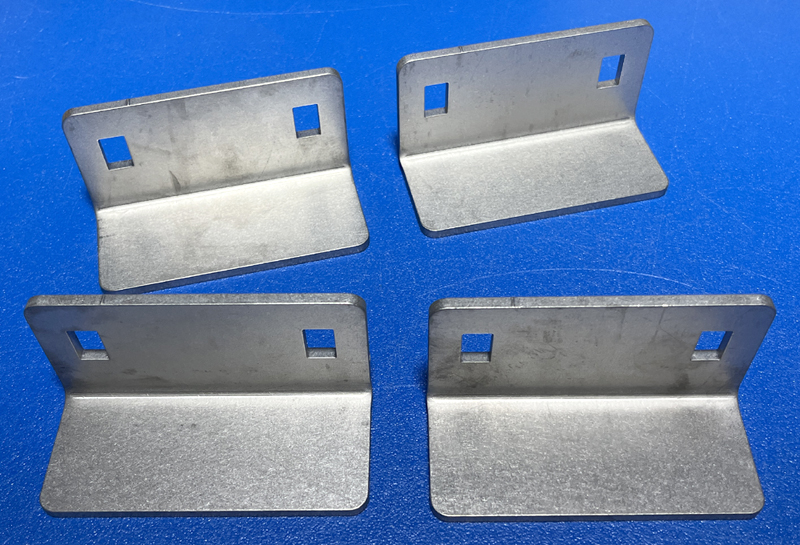

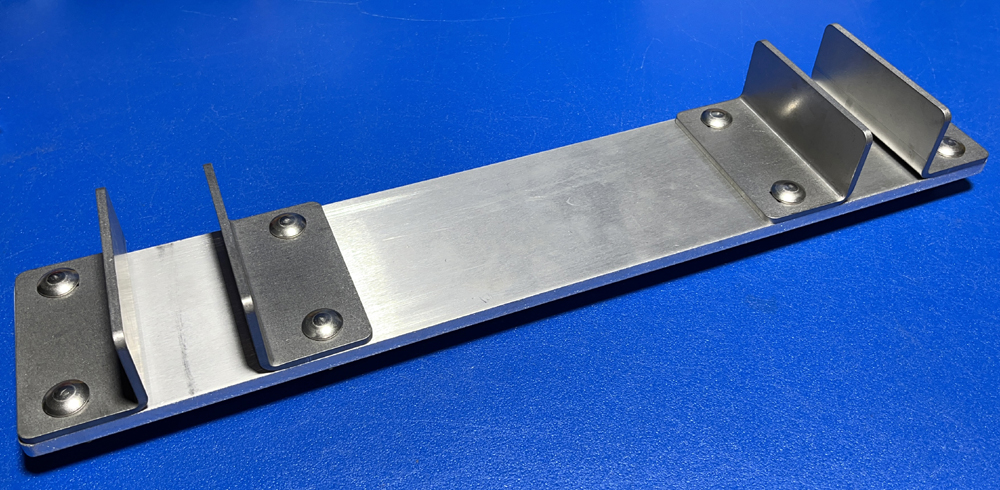

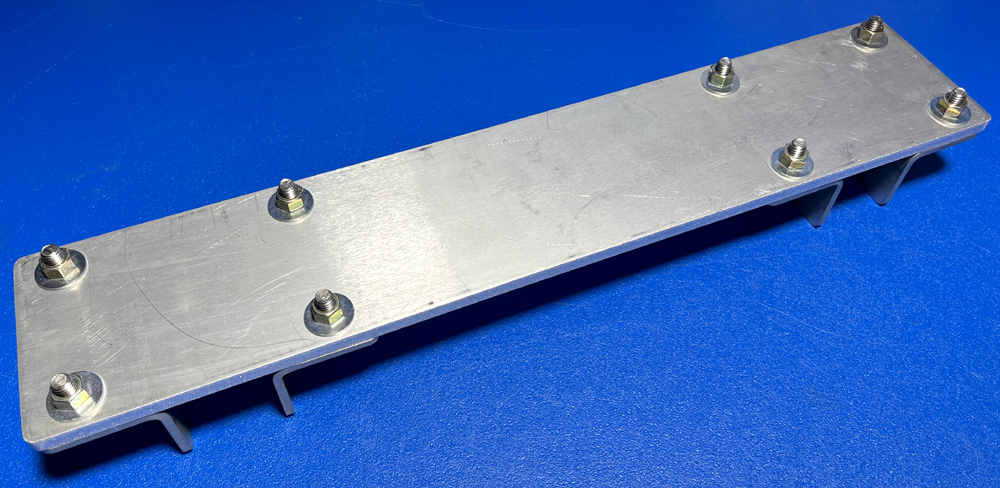

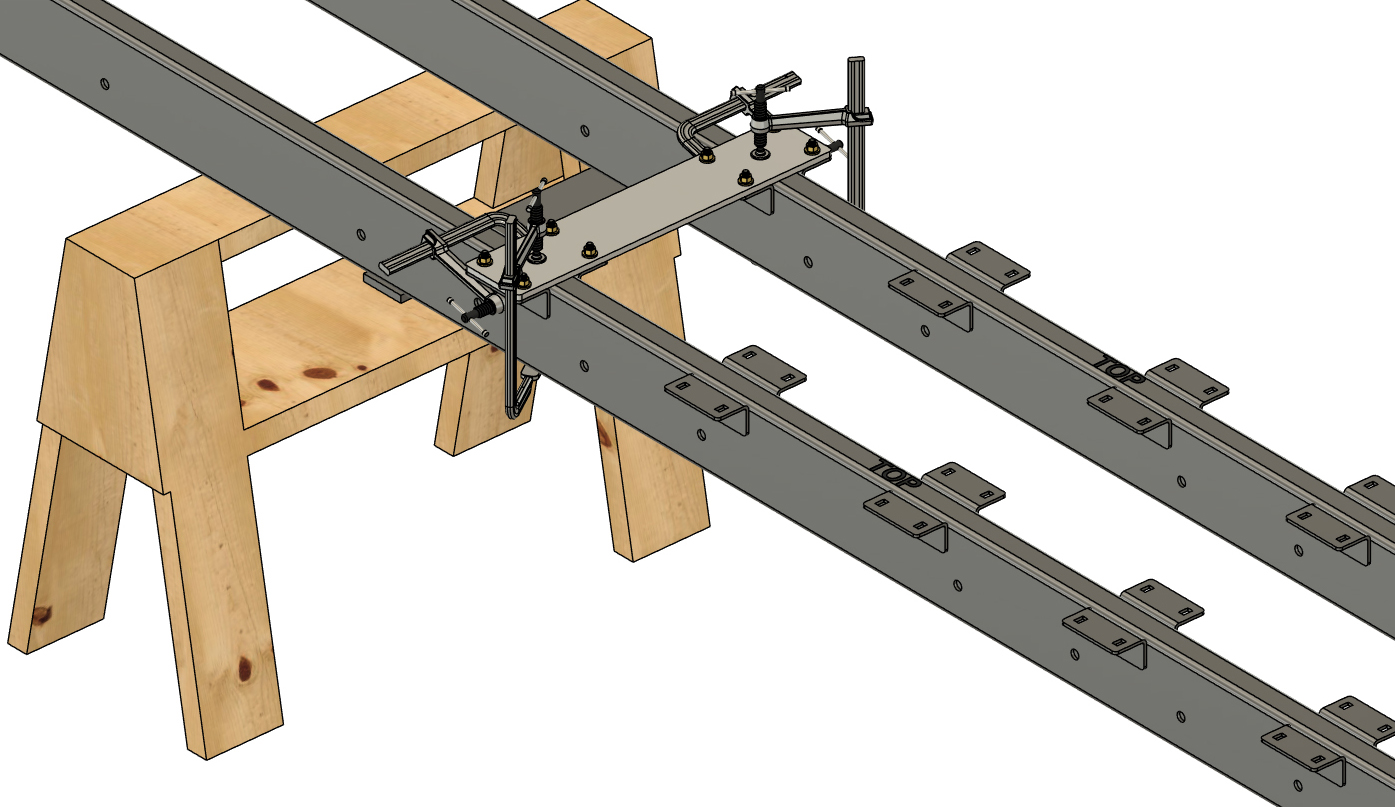

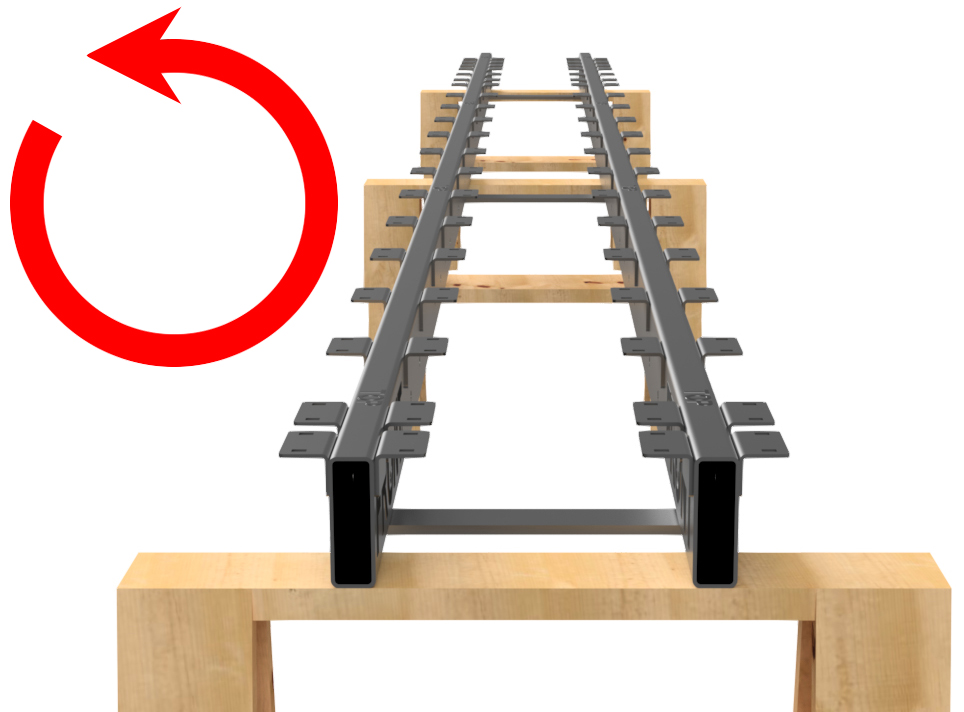

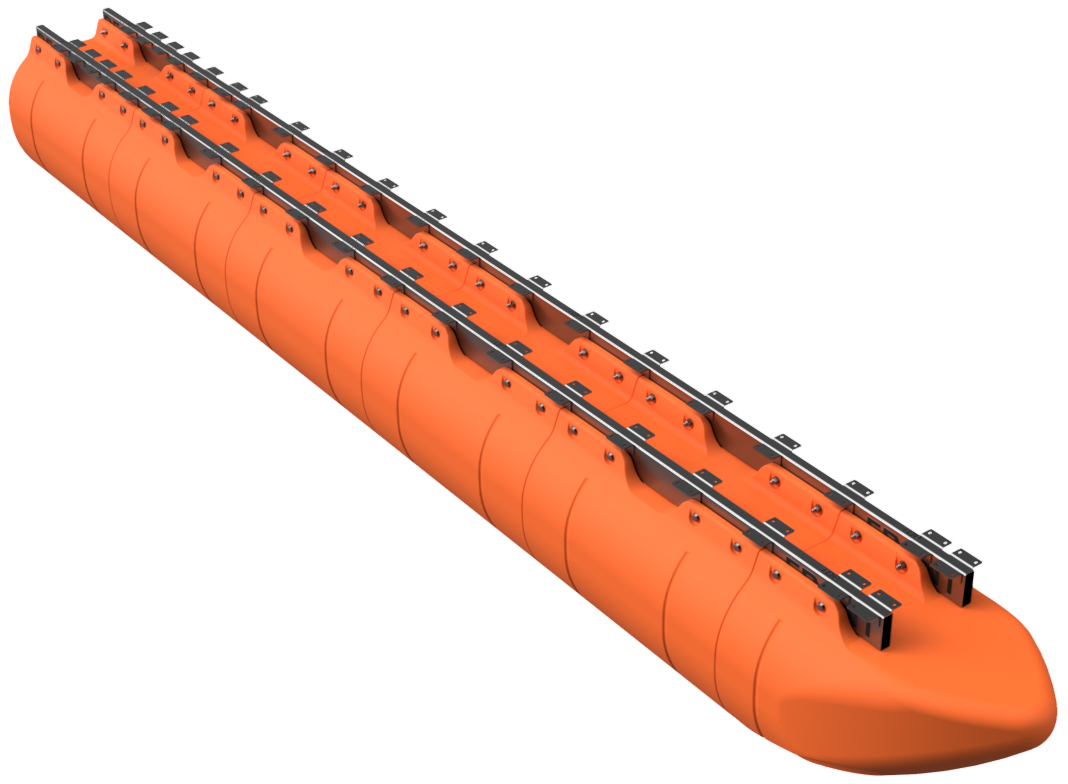

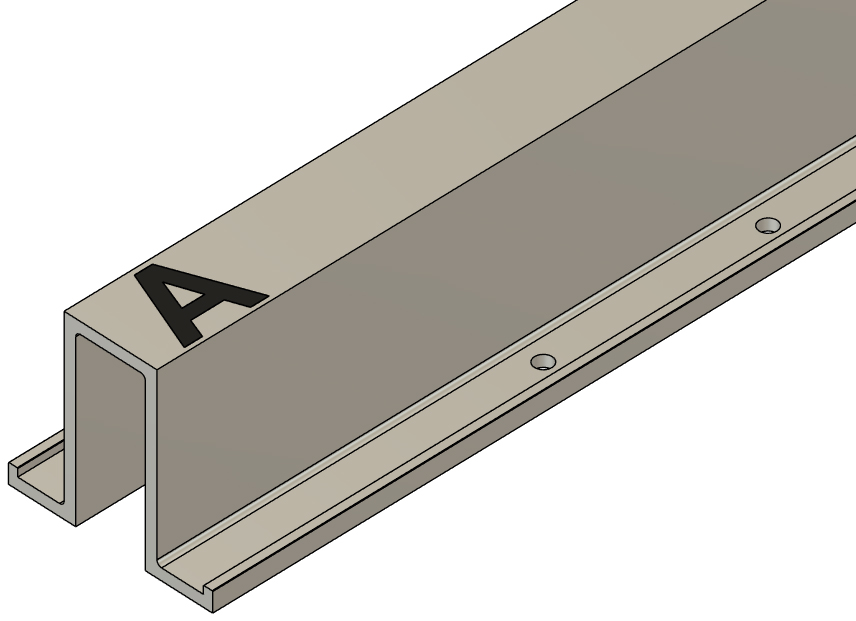

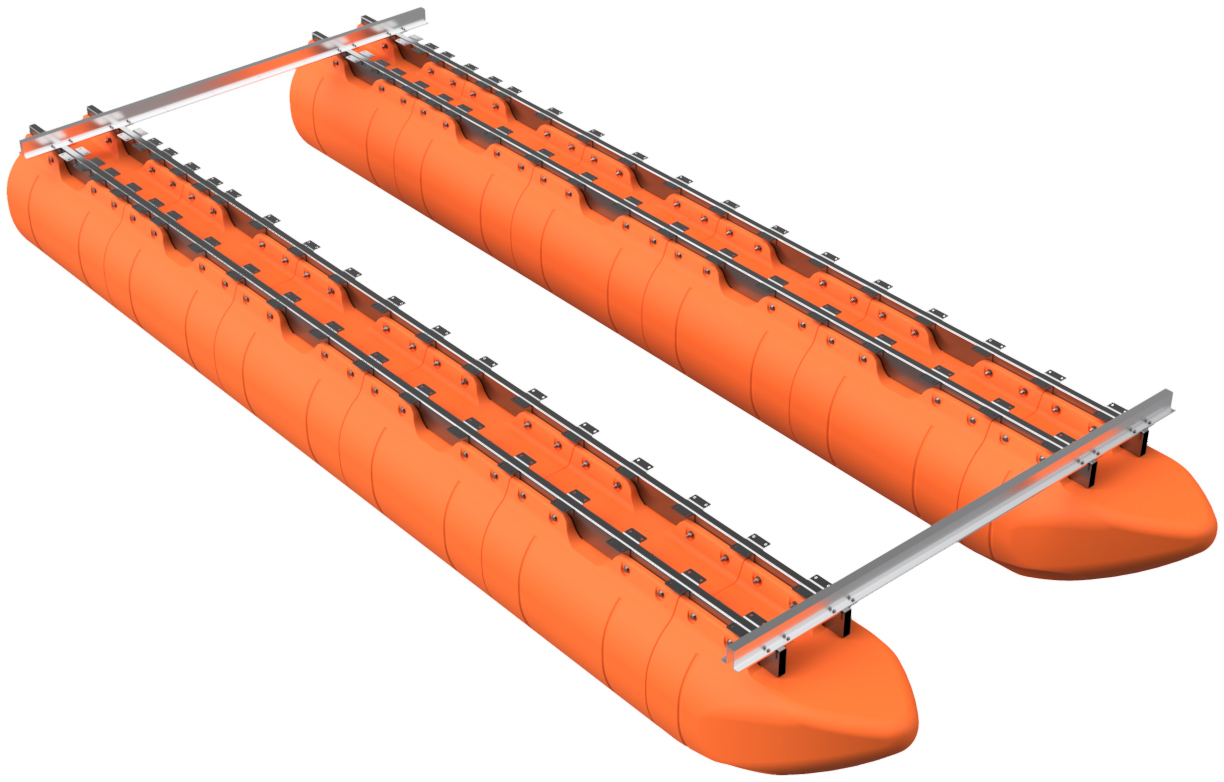

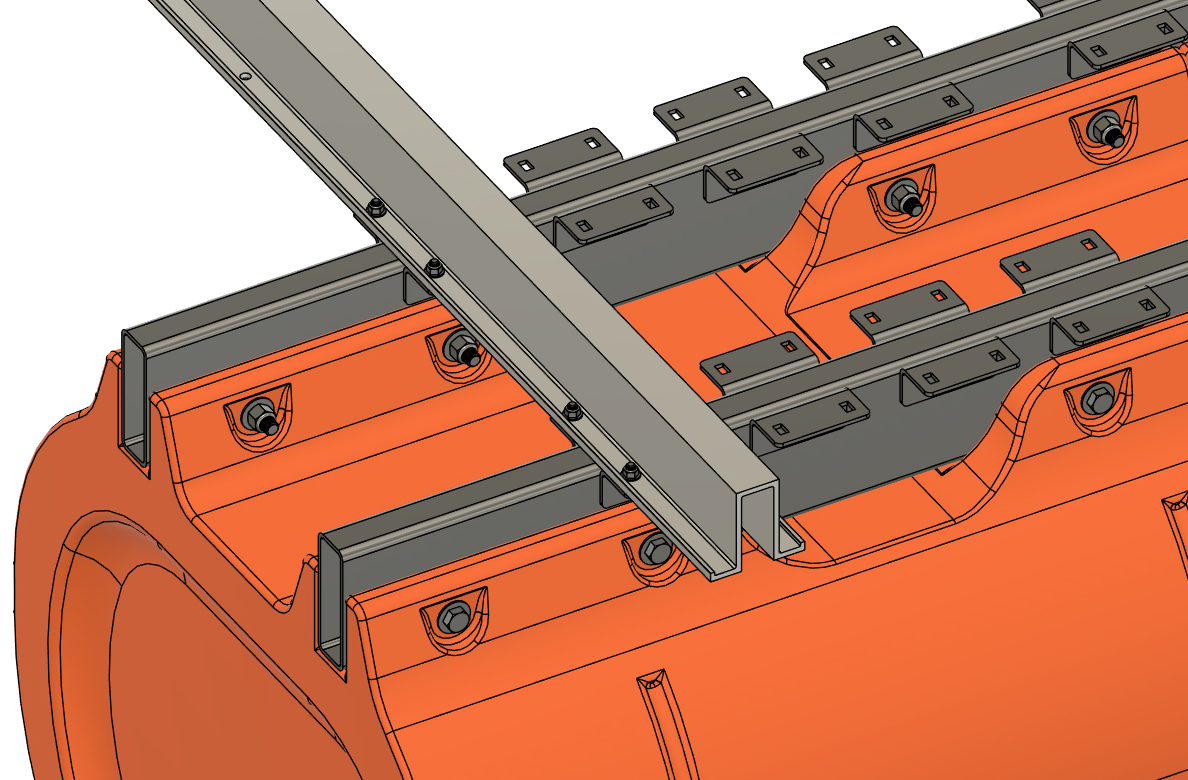

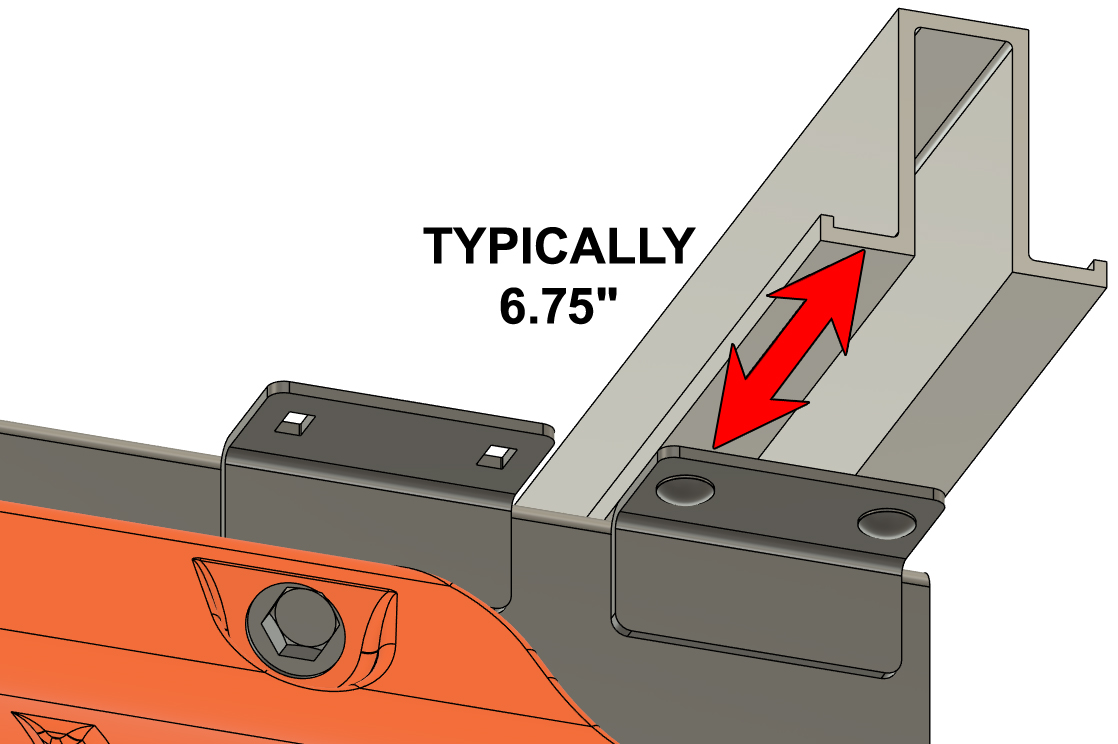

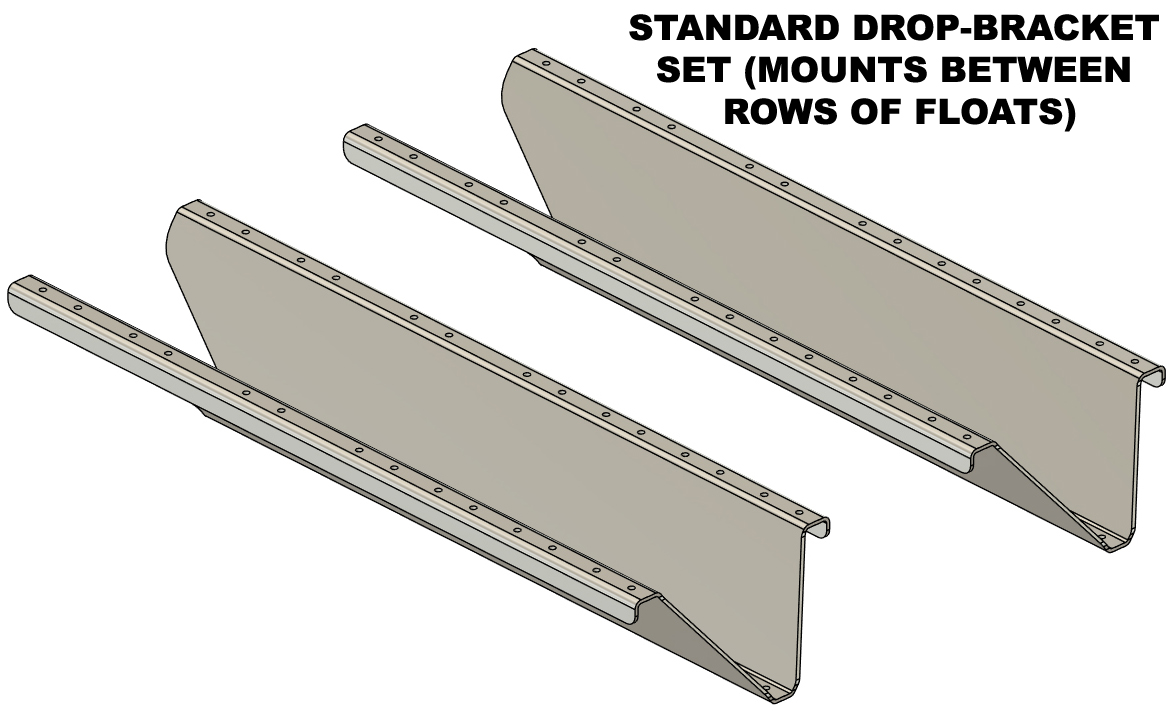

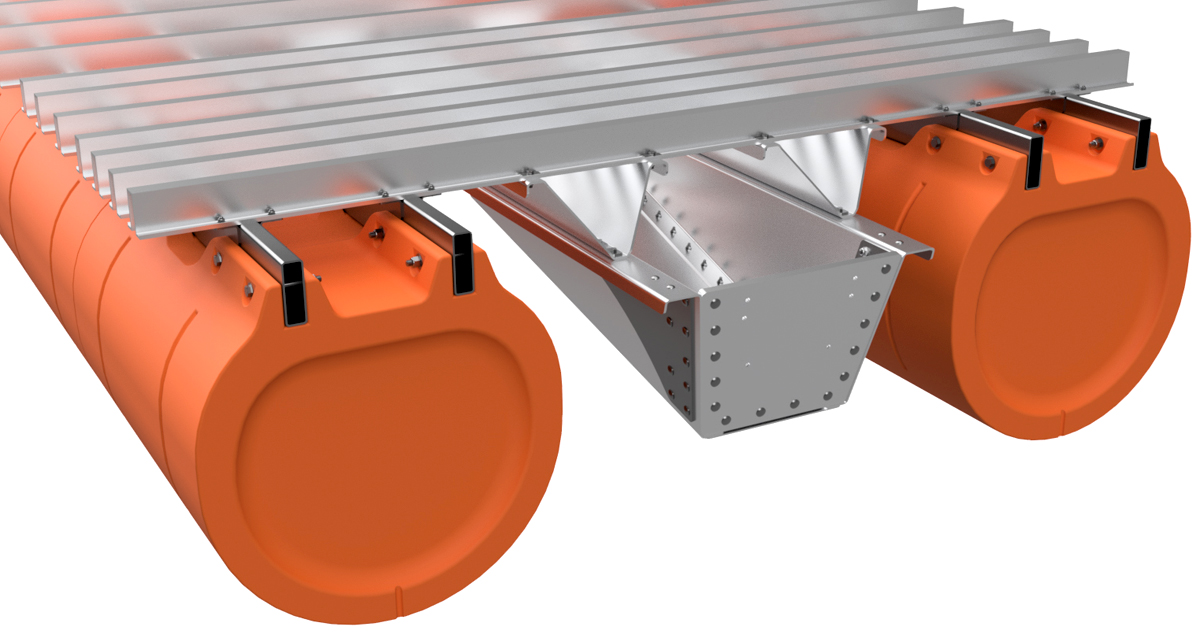

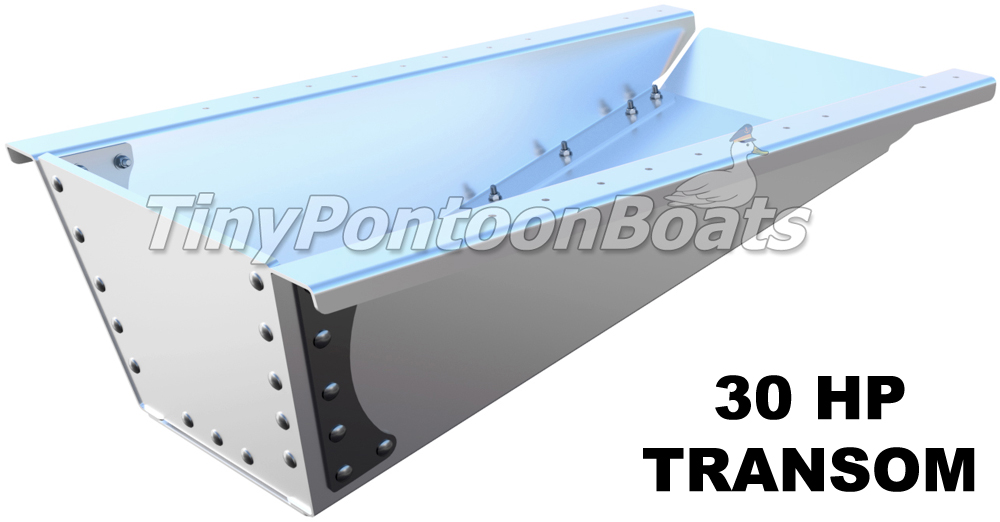

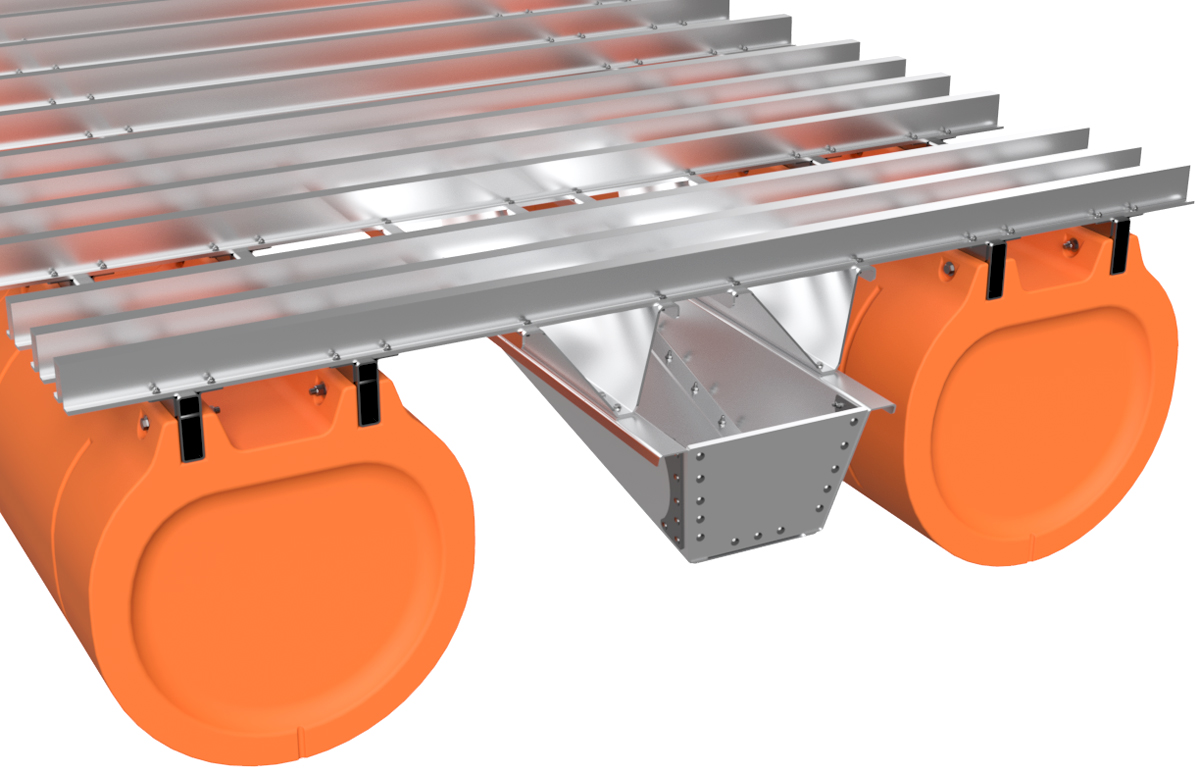

As described on the BigAssPontoonBoats.com main page, our large barge hybrid frame system is a concept that allows you to build a high-quality pontoon platform with the smallest investment possible. With this system, Tiny Pontoon Boats only provides the floats, crossmembers, transom (if you choose to purchase our transom), and a bracket alignment jig plate for physical parts. You are responsible for obtaining the required 6"x2" stainless steel tubes for the pontoon assemblies, weld-on crossmember brackets, 2-4 pieces of stainless flat bar, and assembly hardware (assembly/installation hardware for transoms are included when purchasing our transom systems). This arrangement allows you to build a high-quality large pontoon barge system and keep your costs as low as possible (parts and shipping).

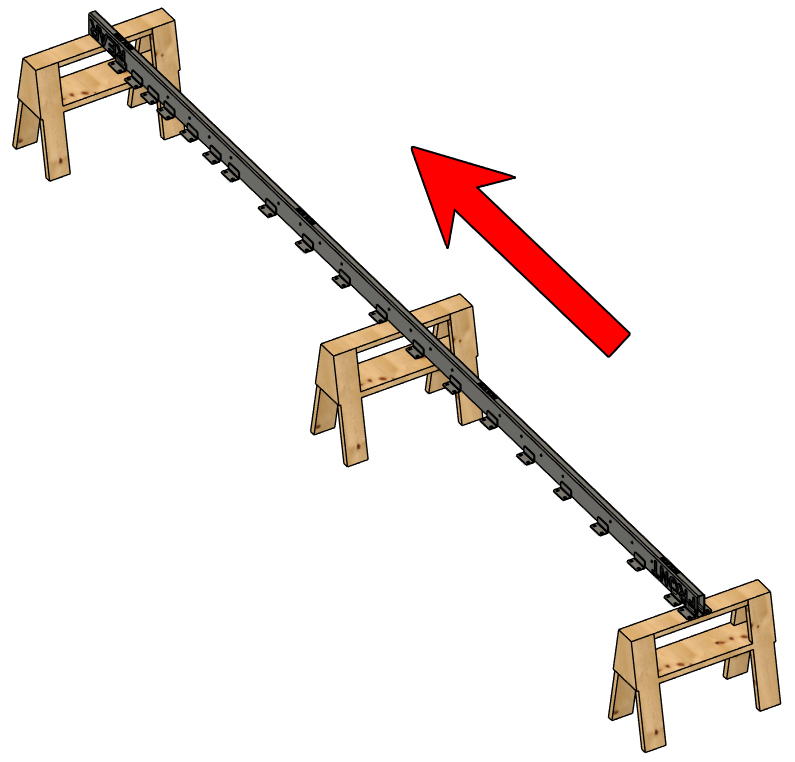

After you purchase your kit, you will be provided with a shopping list that includes required frame tube lengths, weld-on bracket quantities, and a full list of required hardware. We will line up an order for the weld-on brackets through SendCutSend.com (you order directly through them), provide a list of required hardware to purchase from McMaster-Carr, and if requested, we will contact local steel suppliers for quotes on the rectangular frame tubes. We will also provide you with a diagram showing the recommended crossmember/weld-on bracket placement for your barge. The Tiny Pontoon Boats (BigAssPontoonBoats.com) hybrid-framed large barge system is an industrial-sized pontoon barge system that requires welding equipment and experience, lifting equipment, a large work space, as well as larger basic tools to build. If you are not an experienced welder or do not have the equipment we specify, we strongly suggest contacting a local welding and fabrication shop to complete your assembly. This is NOT an "anyone can do it" system, so don't fool yourself if you don't have the proper equipment or skills to carryout one of these builds. Also, the components of these systems are large and heavy, especially as your assembly moves forward. Moving parts and assemblies for this system will require lifting equipment (forklift, loader, or over-head hoist system). Unlike our smaller bolt-together boat systems, our hybrid-frame large barge systems don't allow for error in assembly and failure to follow our instructions can cause expensive, or at least time consuming errors. Take your time, work as a team (not a single-person project), and follow our instructions closely. If questions occur, CALL US. |

|

REQUIRED TOOLS & MATERIALS

Construction of your hybrid-framed barge sytem requires both advanced and basic tools. These kits require welding and lifting equipment, as well as simple fabrication tools and wrenches. Below we have provided a list of the tools required for construction for this type of barge sytem.

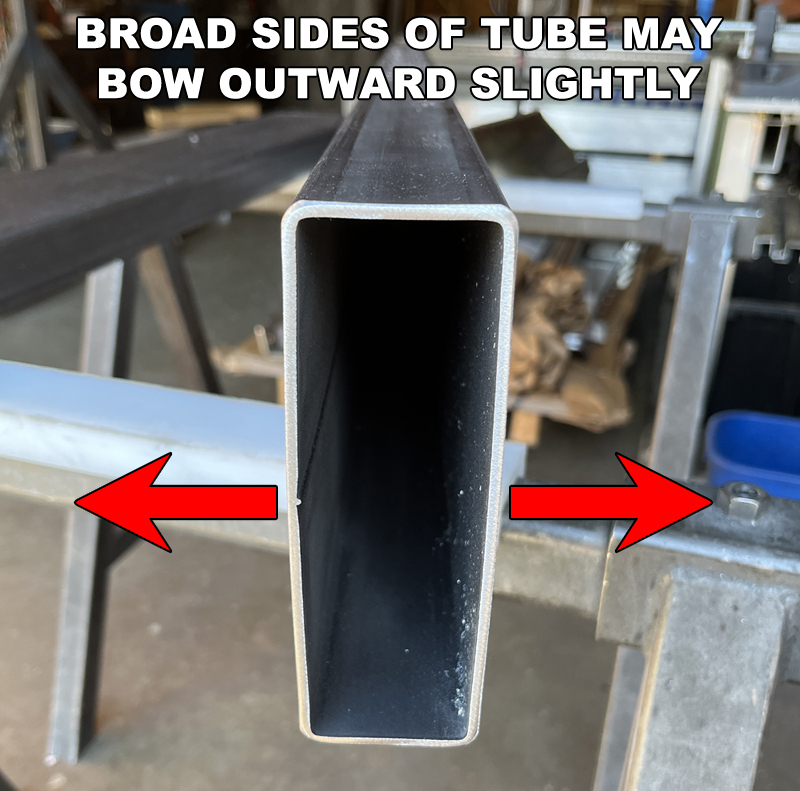

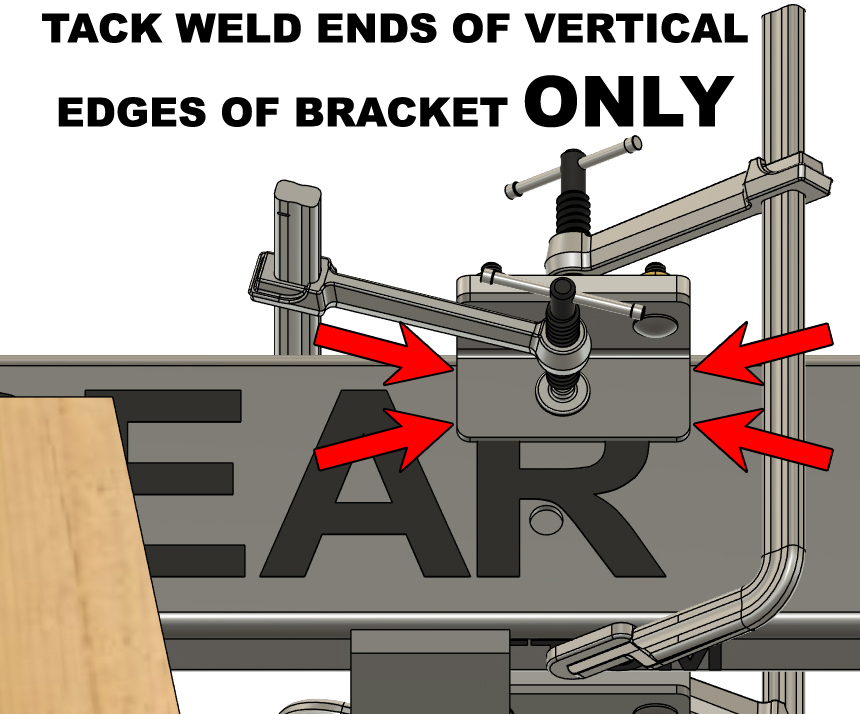

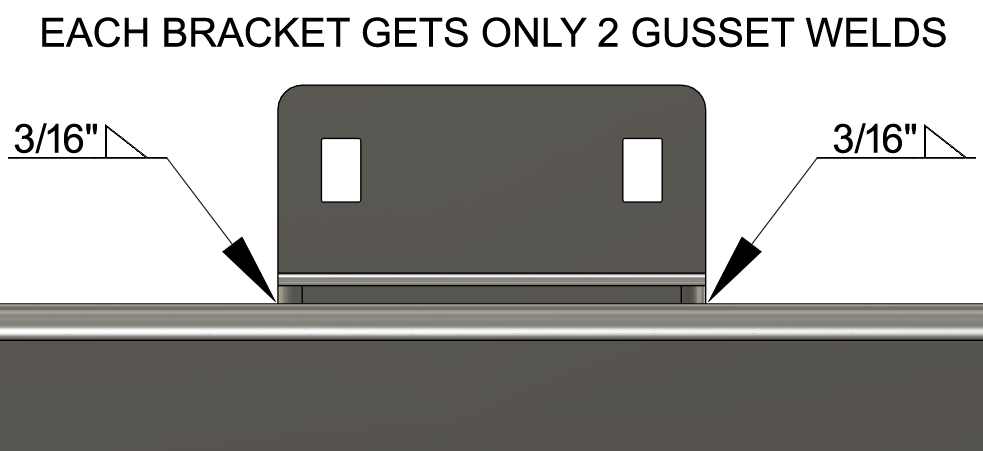

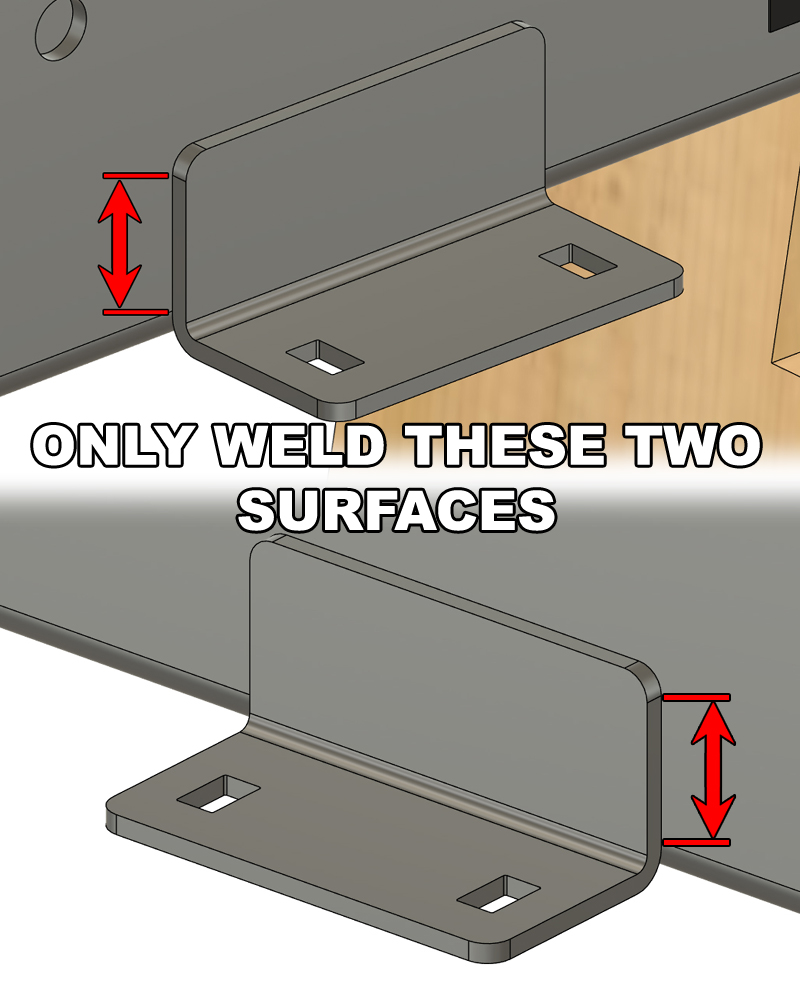

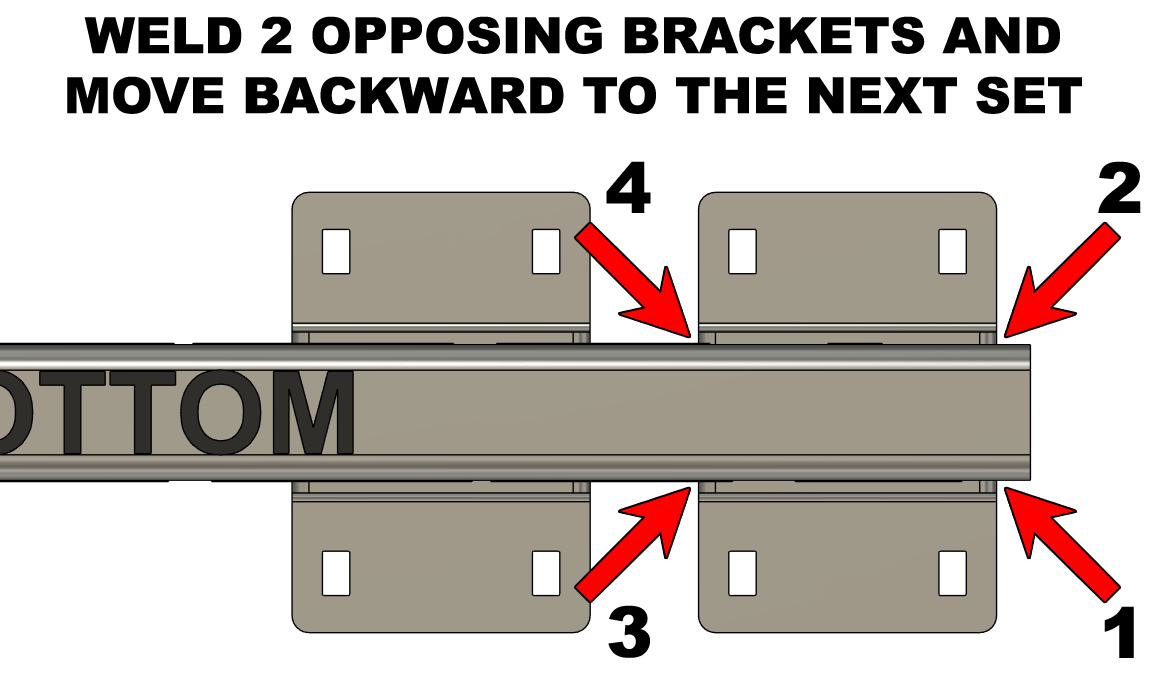

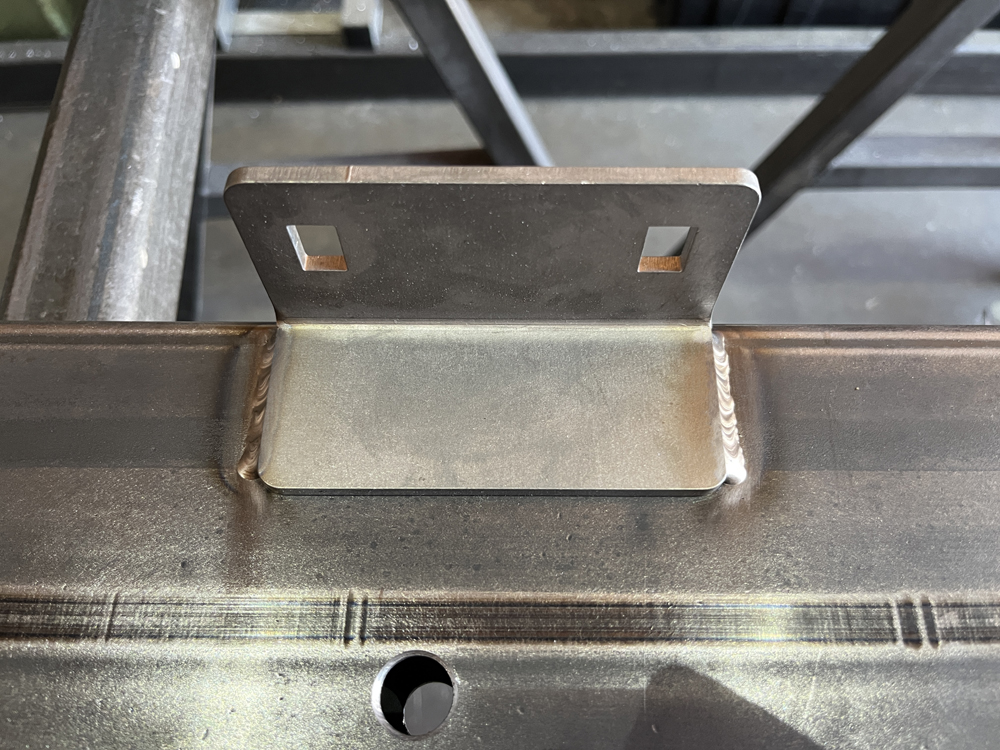

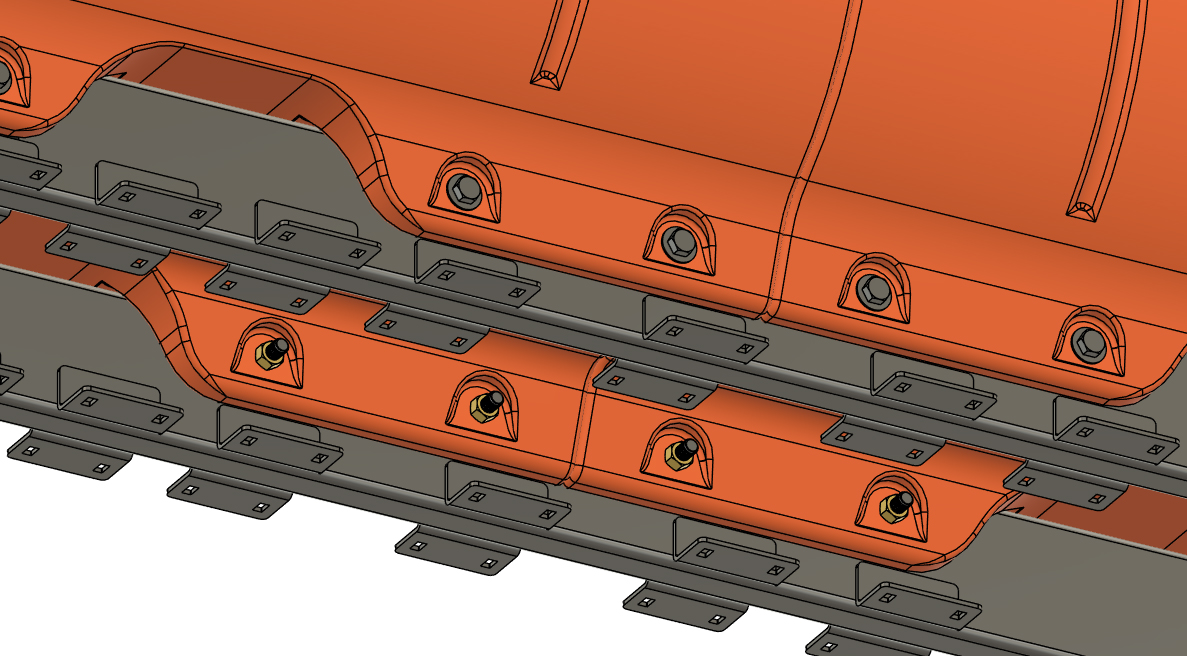

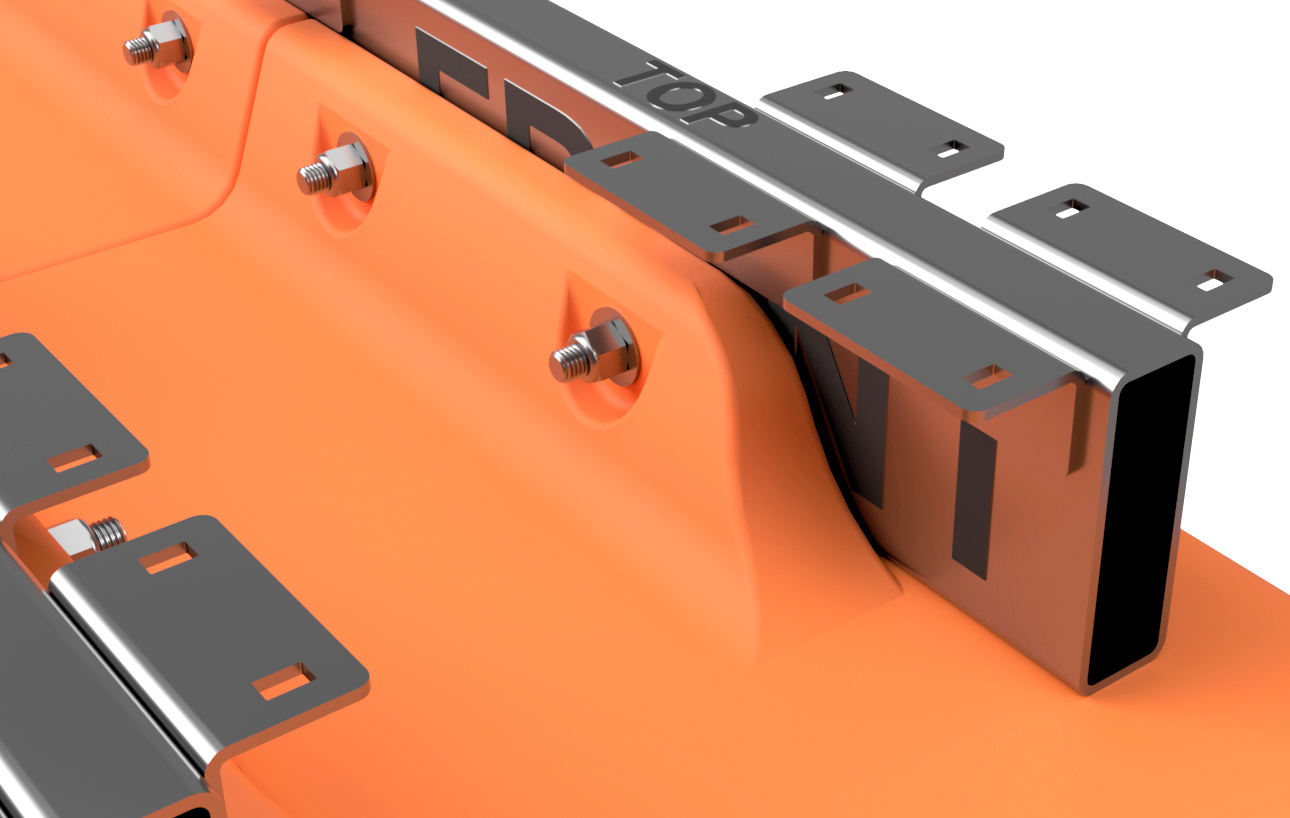

PRO TIP: This system requires welding of 3/16" thick stainless crossmember mounting brackets to a stainless tube that fits into your pontoon floats. We strongly recommend TIG or laser welding these brackets in place. MIG or stick welding is far more likely to cause distortion of the 6"x2" tube the brackets get attached to and we strongly recommend against using MIG or stick welding methods when building this system. If you are building multiple barges, or setting up a new production line for assembly of our hybrid frame systems, we recommend a wire-feed laser welder like the EverLast Redsabre machines. These machines require little training and provide high-quality results with very little distortion. If you're shopping for this sort of equipment, please do us a favor and click on our affiliate link below. In our example pictures, our welds will be completed with a Miller Dynasty TIG welder by our in-house master welder (25+ years of experience). Below we have provided two lists. One list is the required tools and the other is for the materials, parts, and hardware required for this system that are NOT provided by Tiny Pontoon Boats. Once again, we will provide you with the quantities required for anything you need to obtain after your order is placed, or prior per request. REQUIRED TOOLS

REQUIRED MATERIALS & HARDWARE

(NOT INCLUDED - REQUIRED QUANTIES VARY)

|

|

|

STEP 3

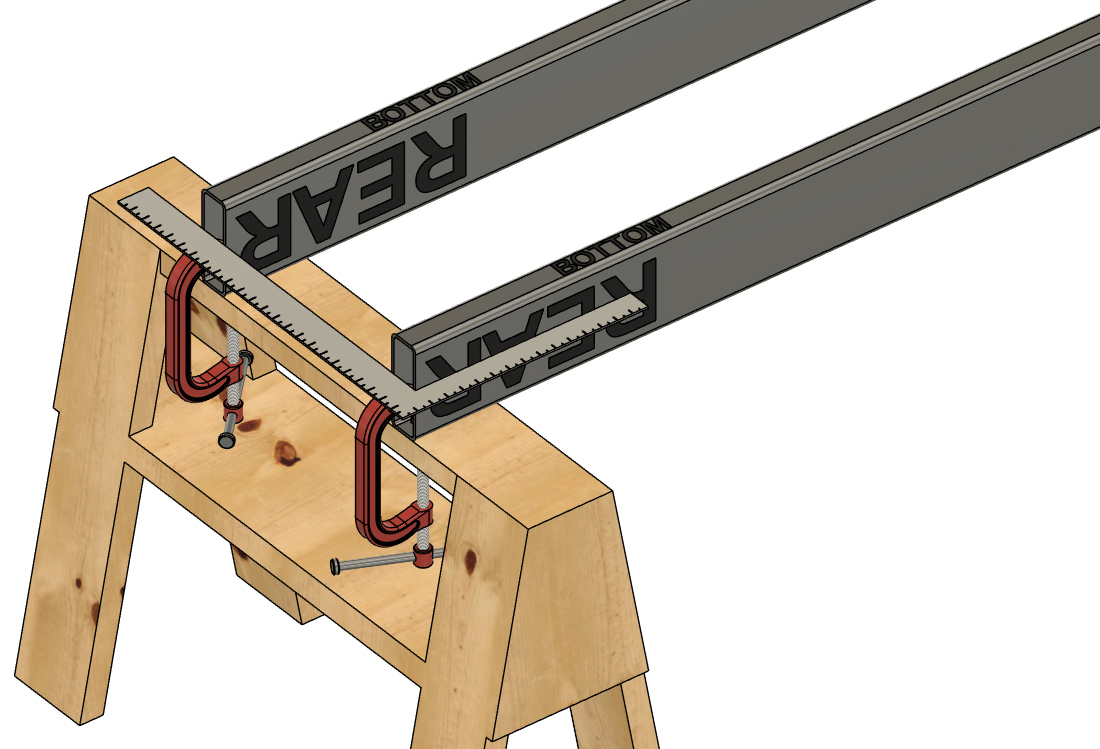

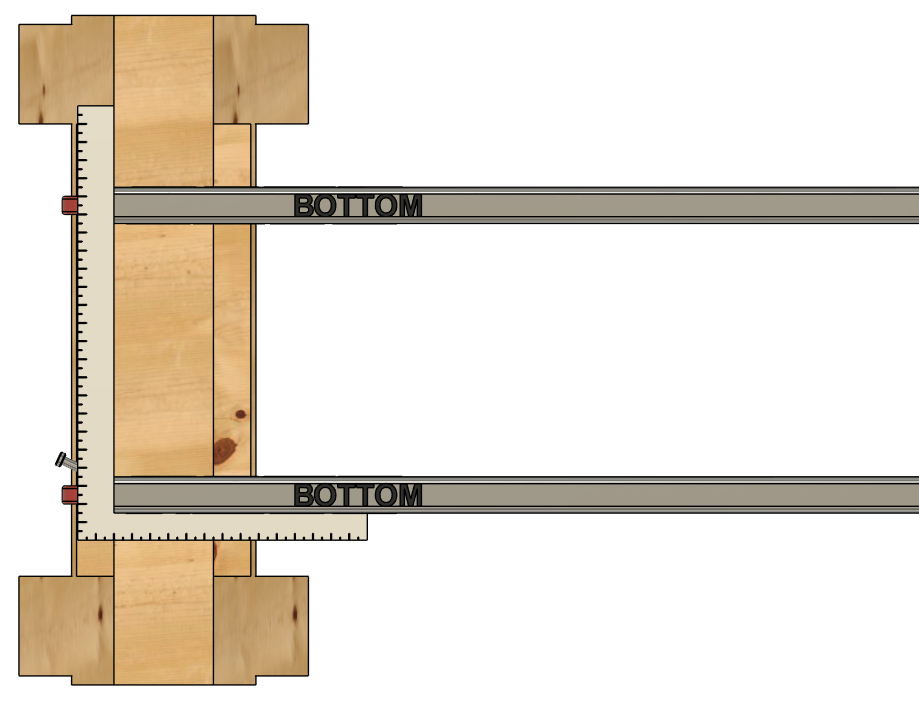

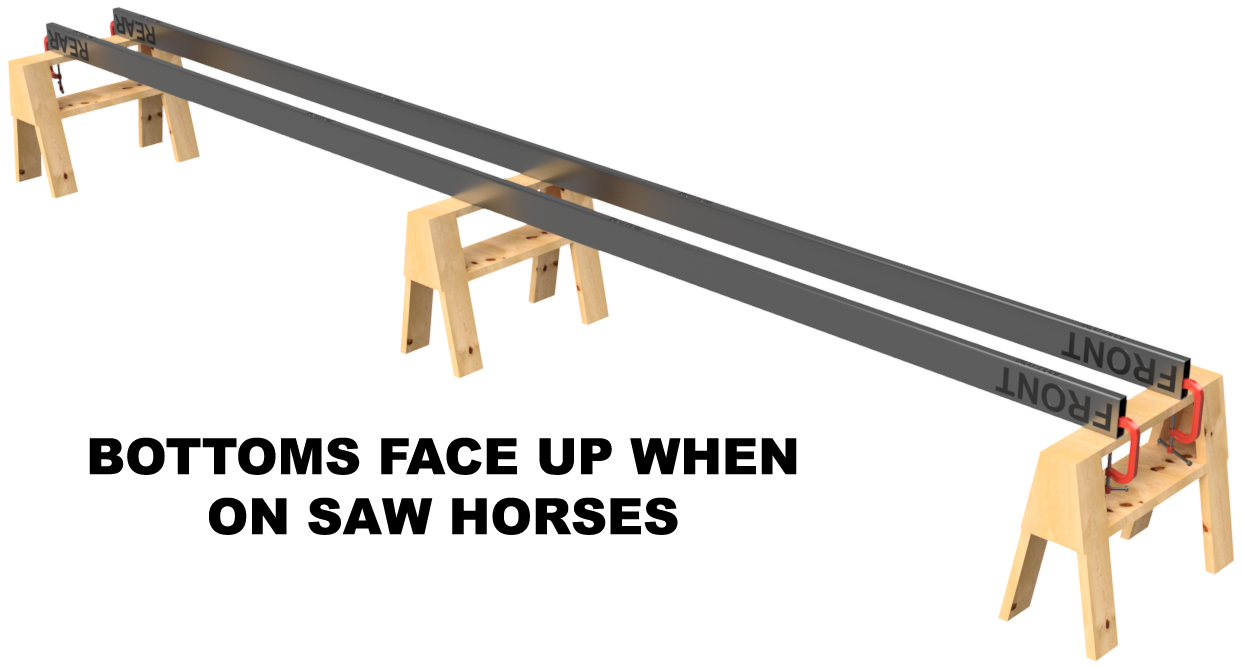

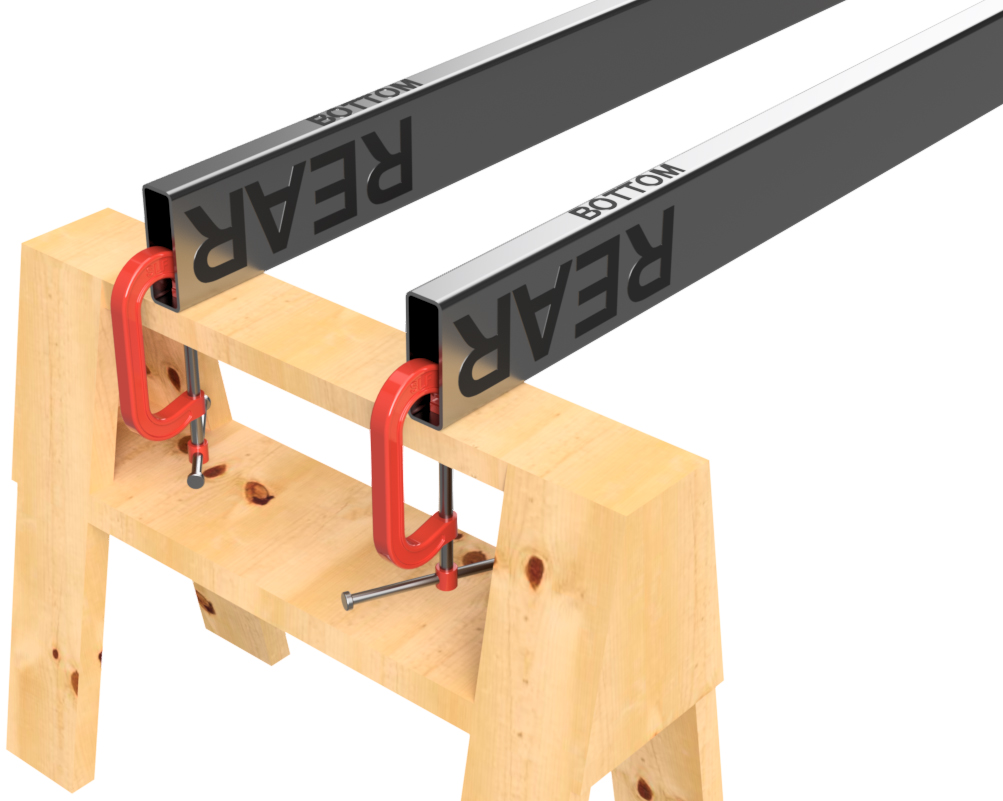

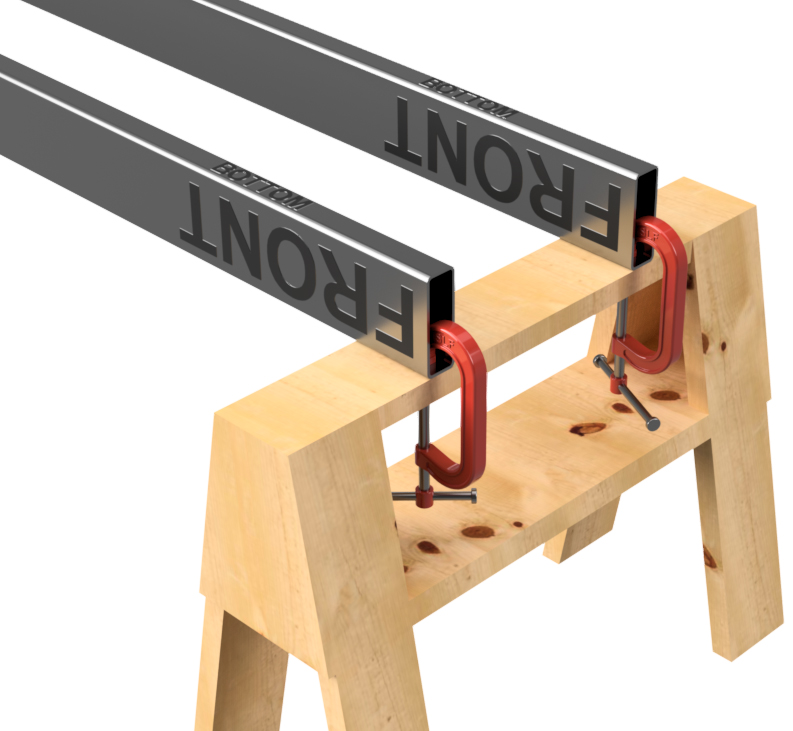

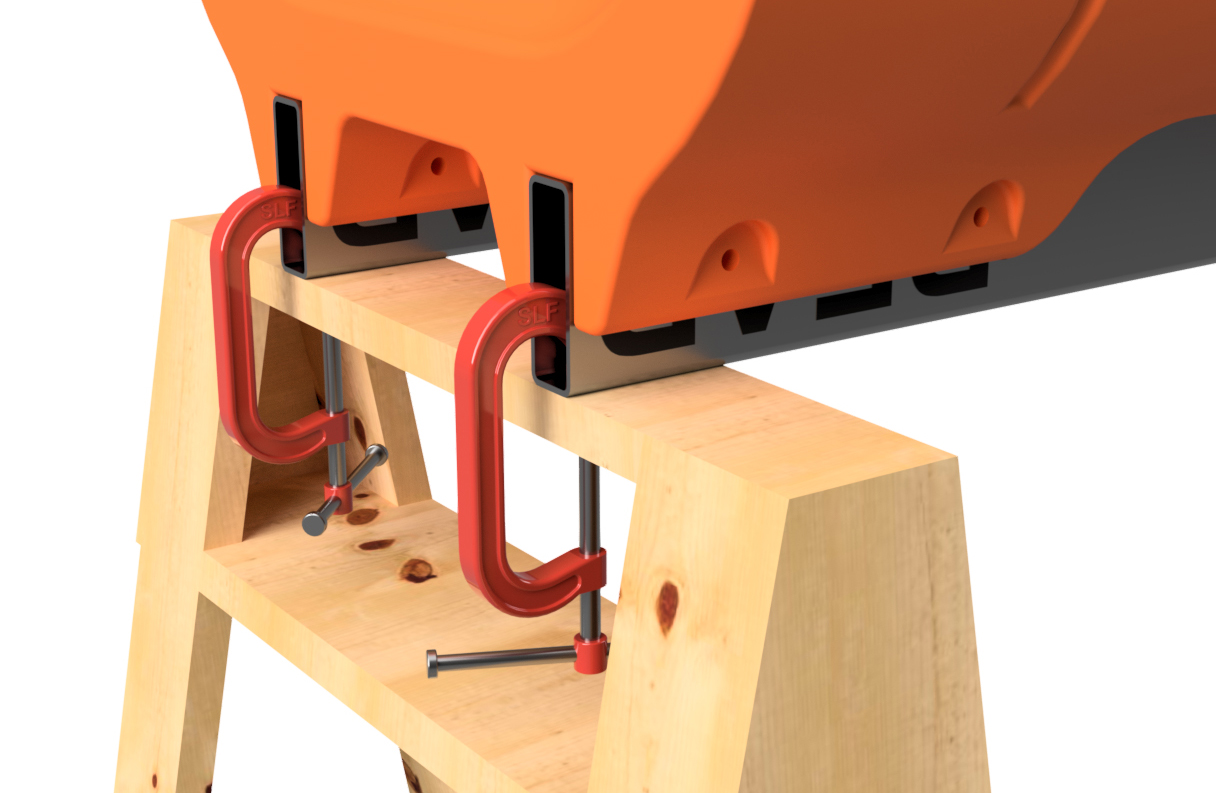

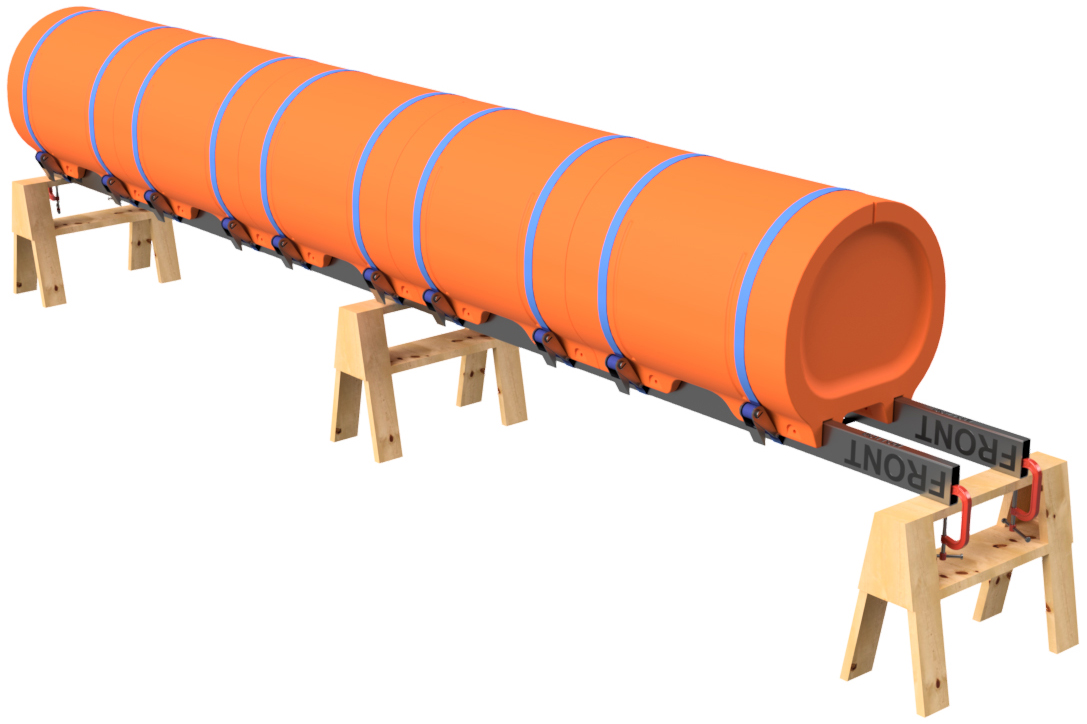

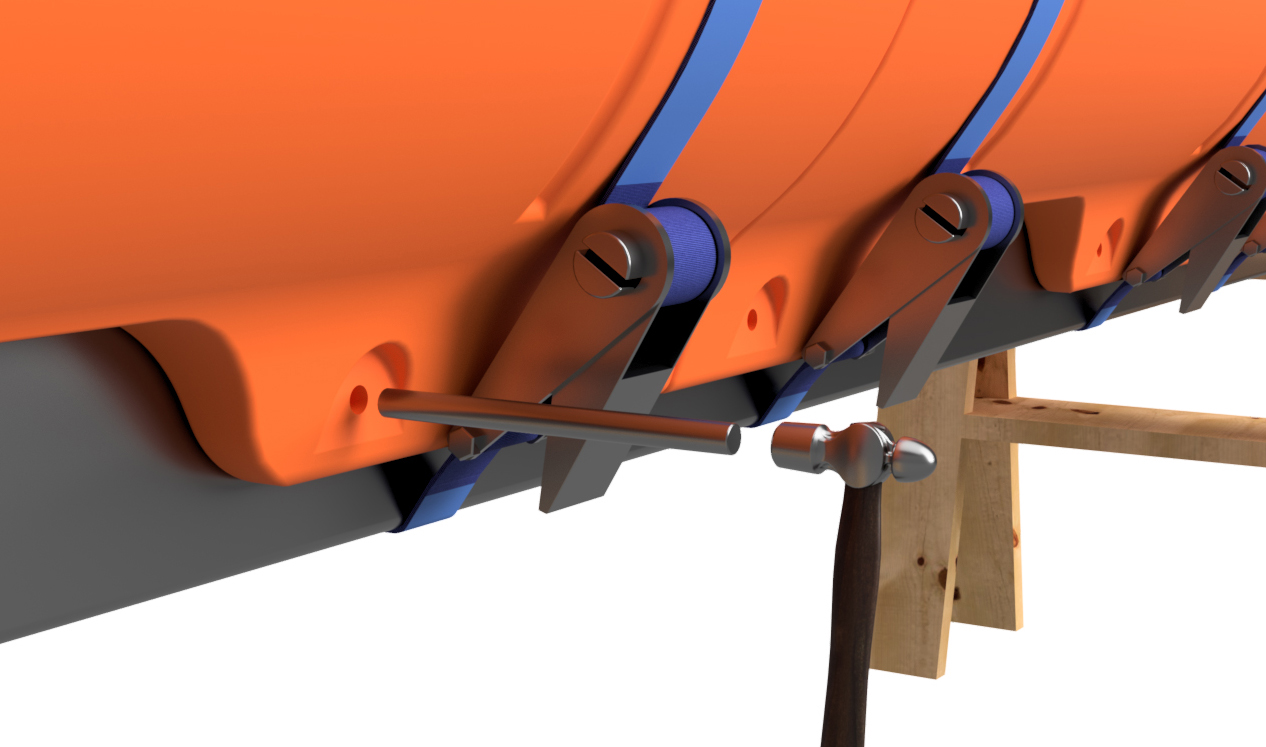

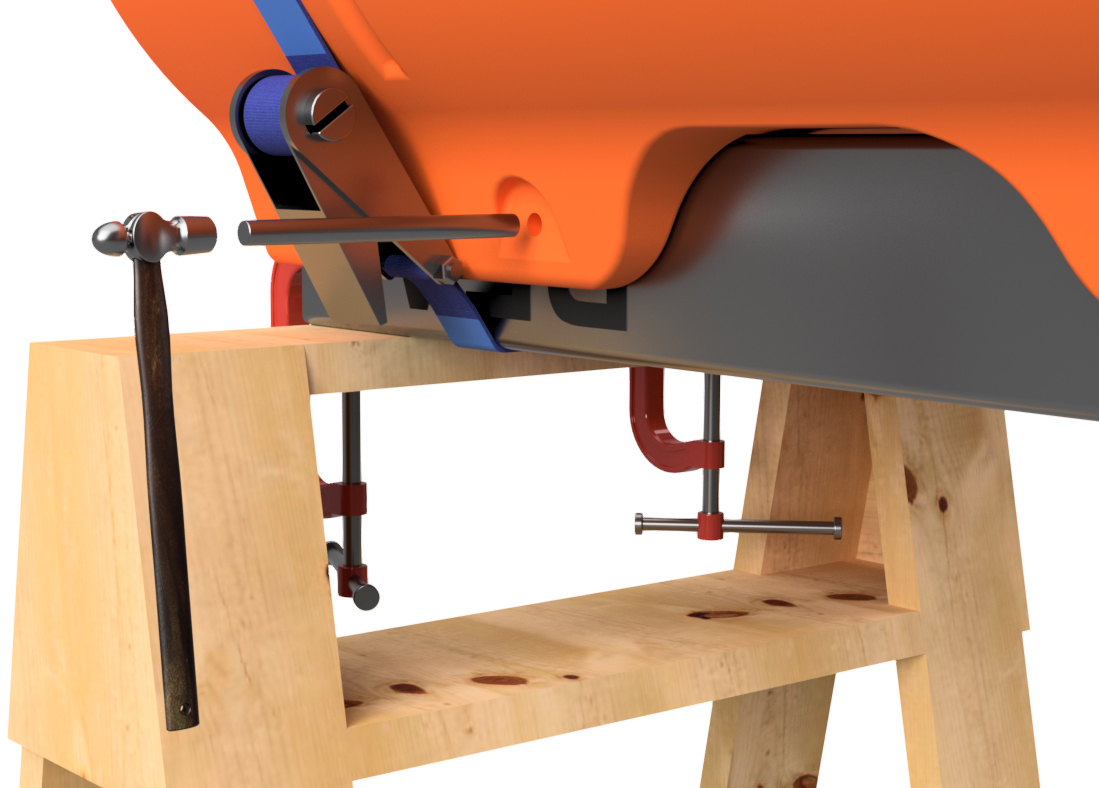

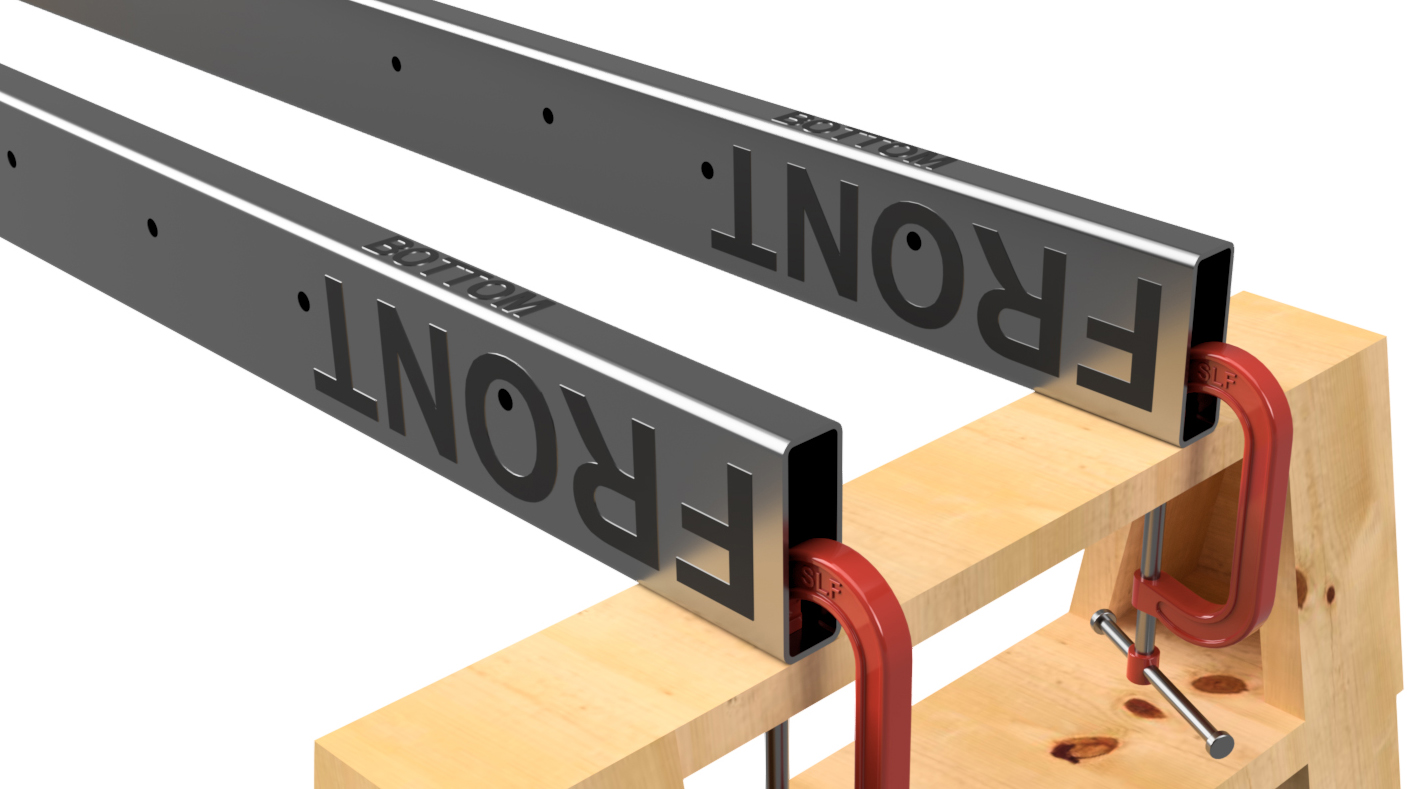

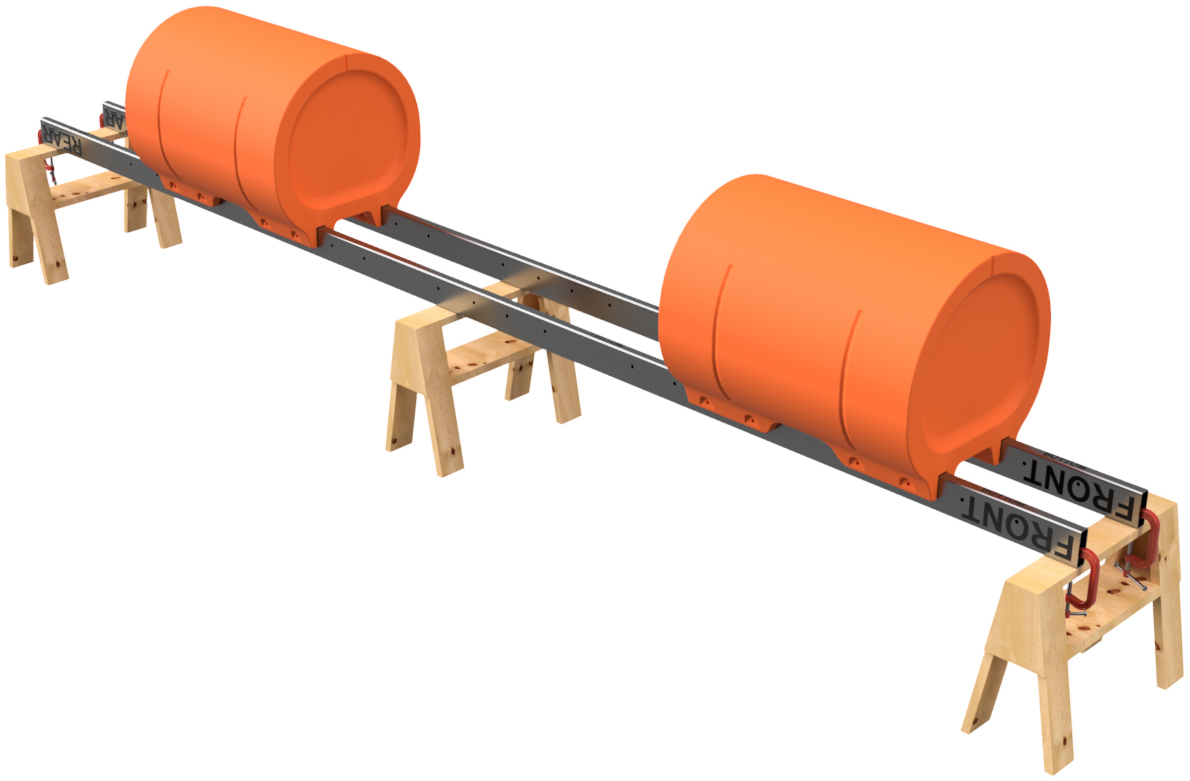

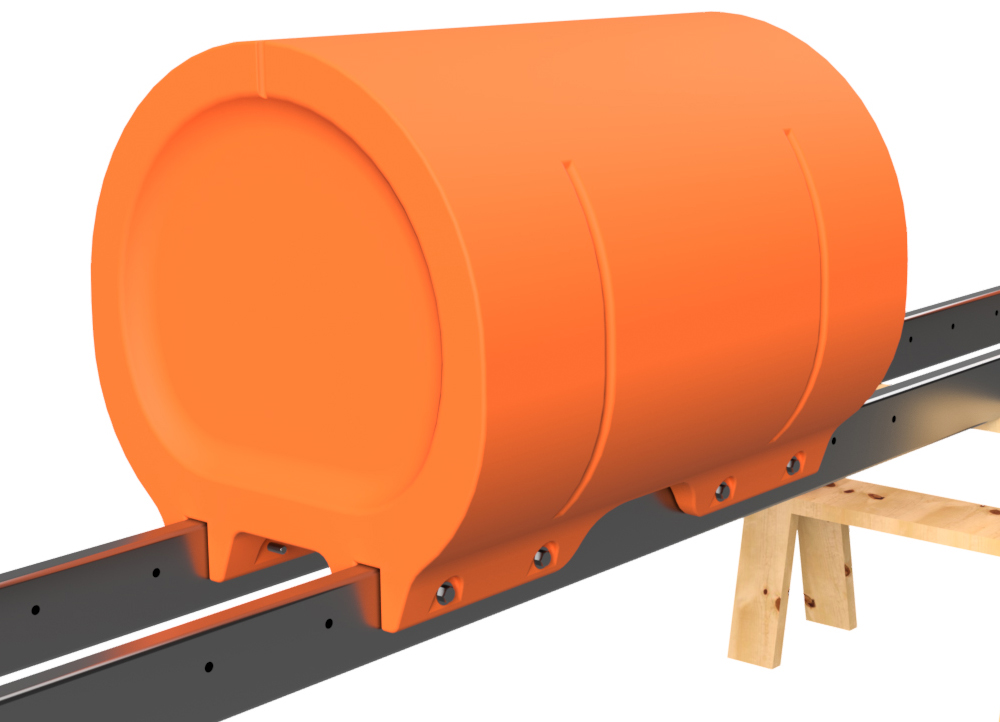

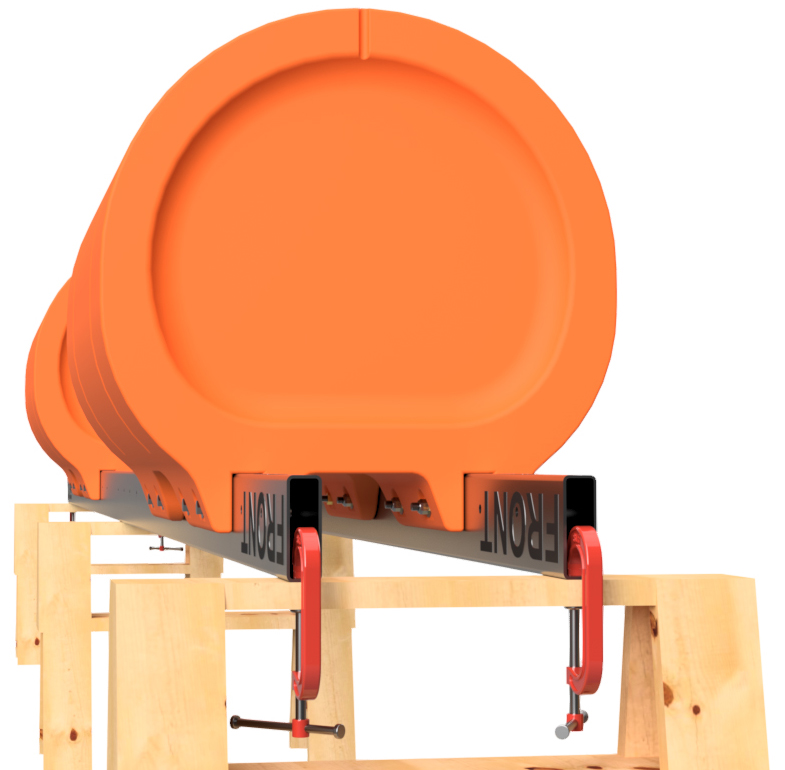

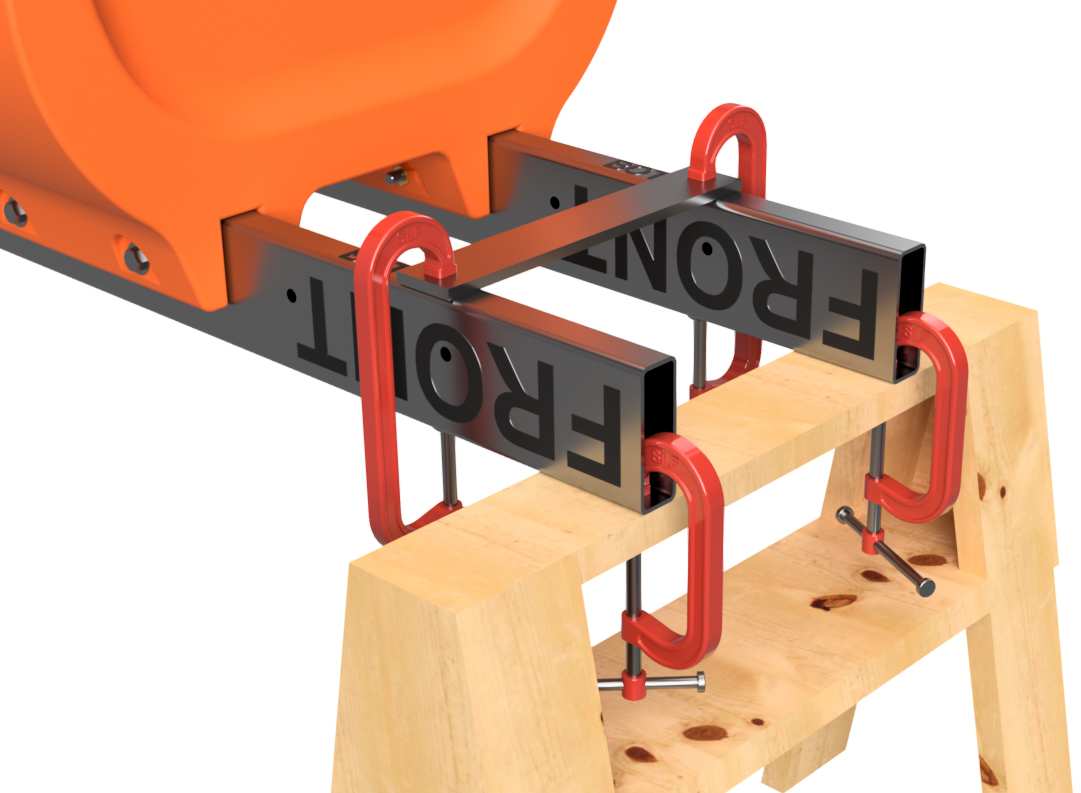

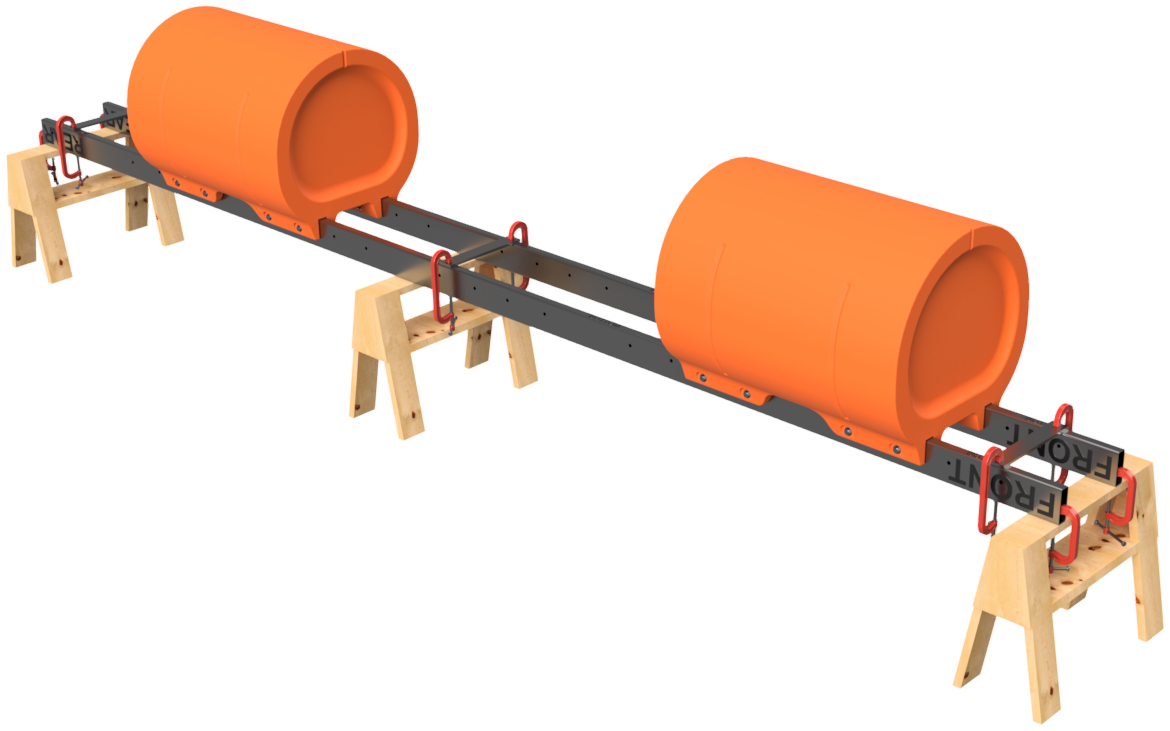

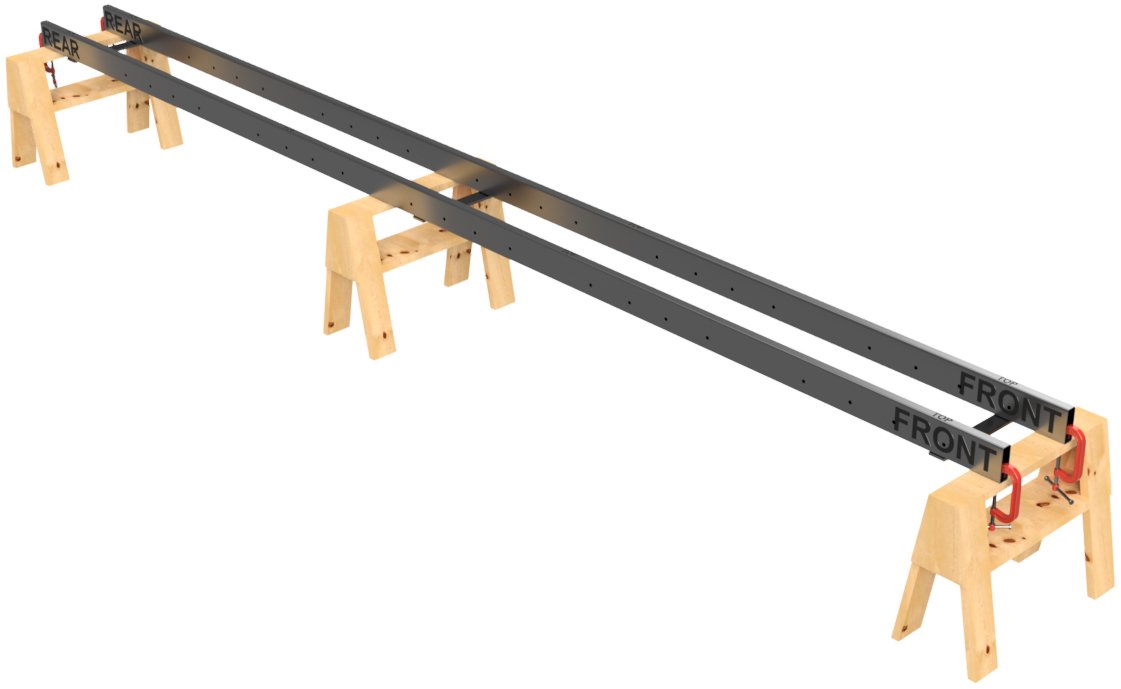

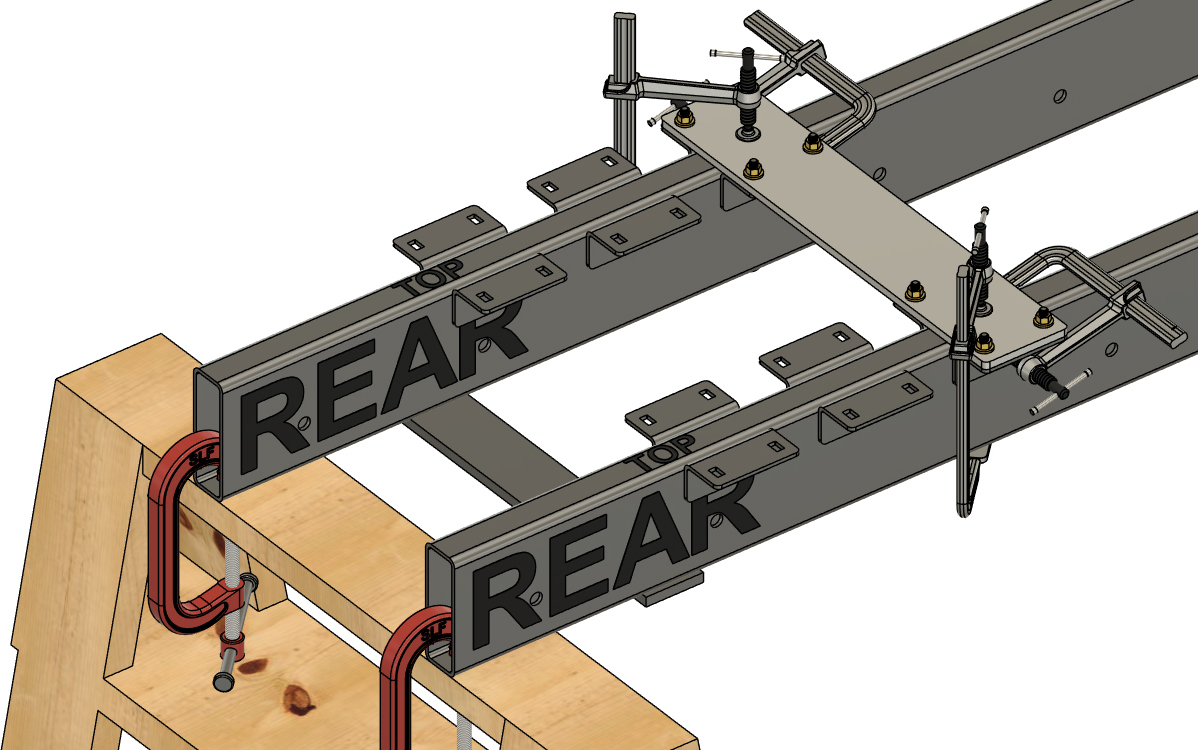

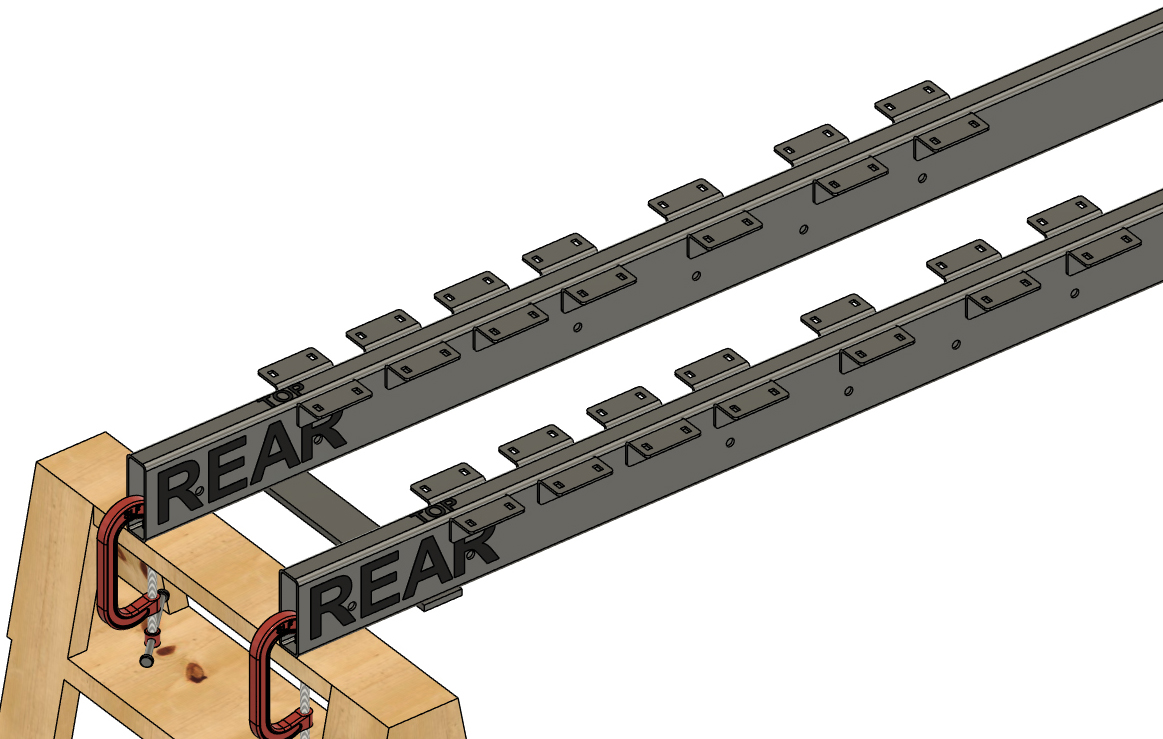

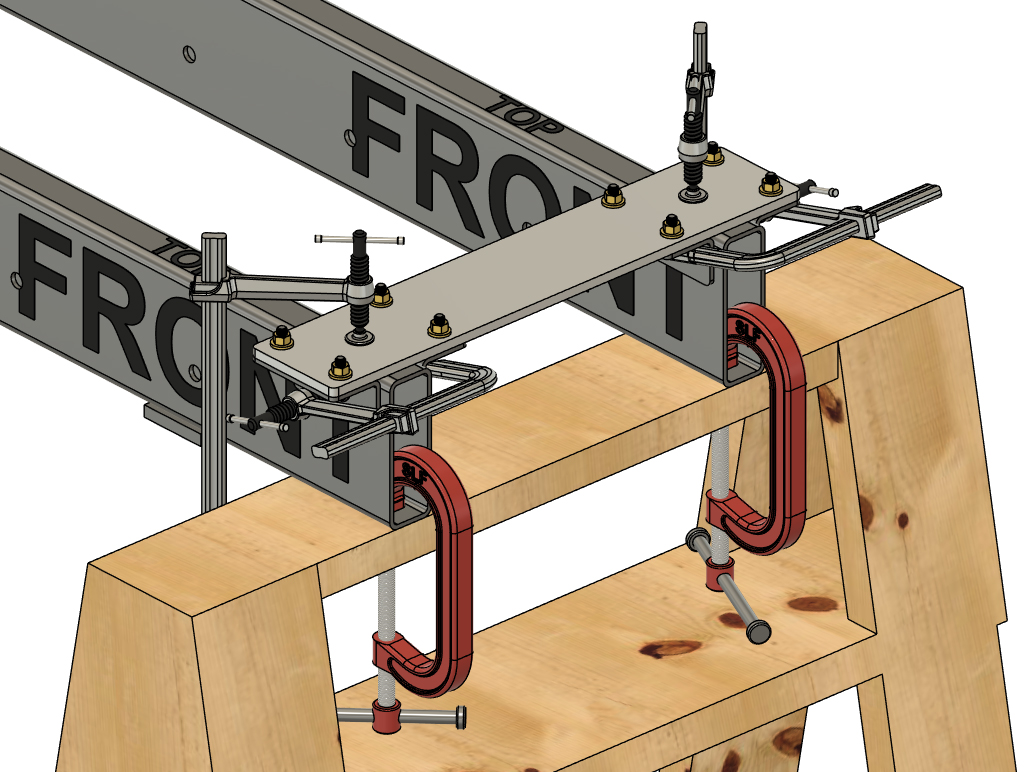

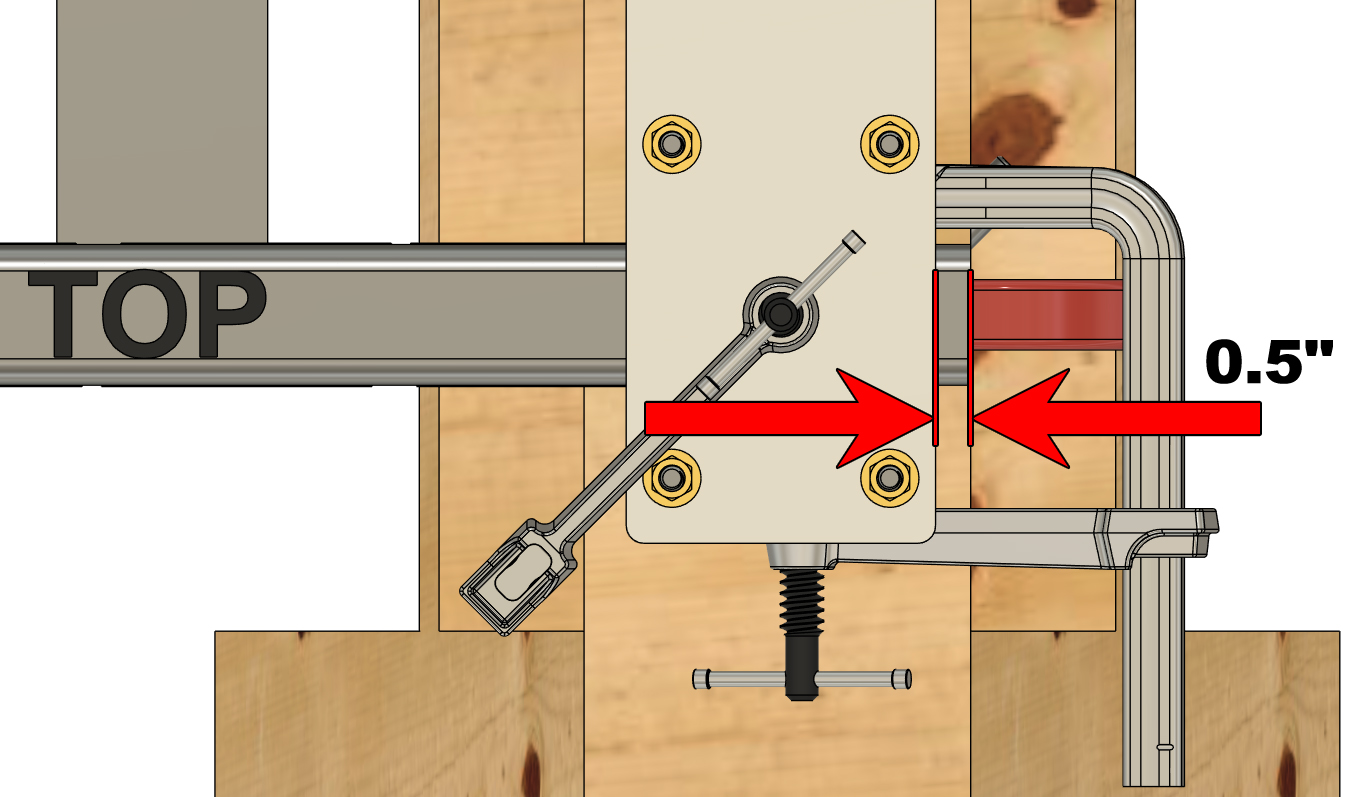

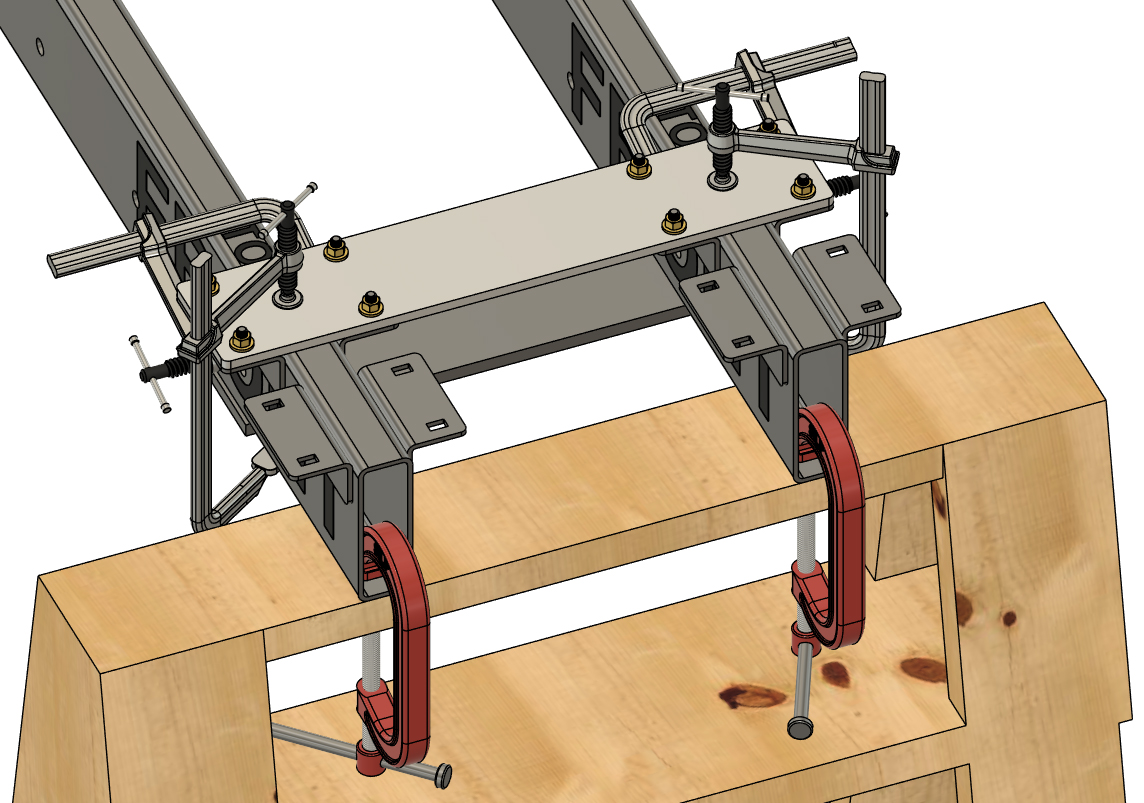

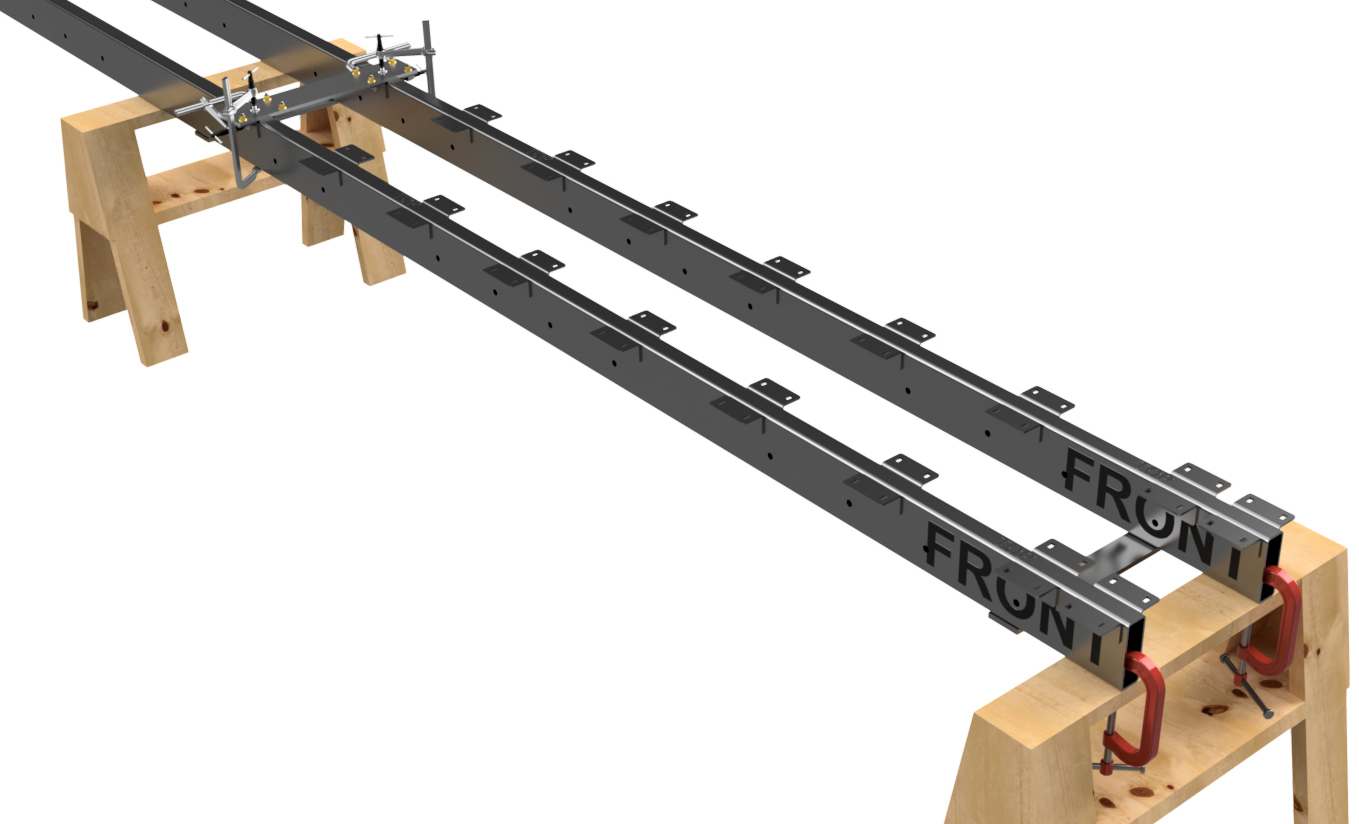

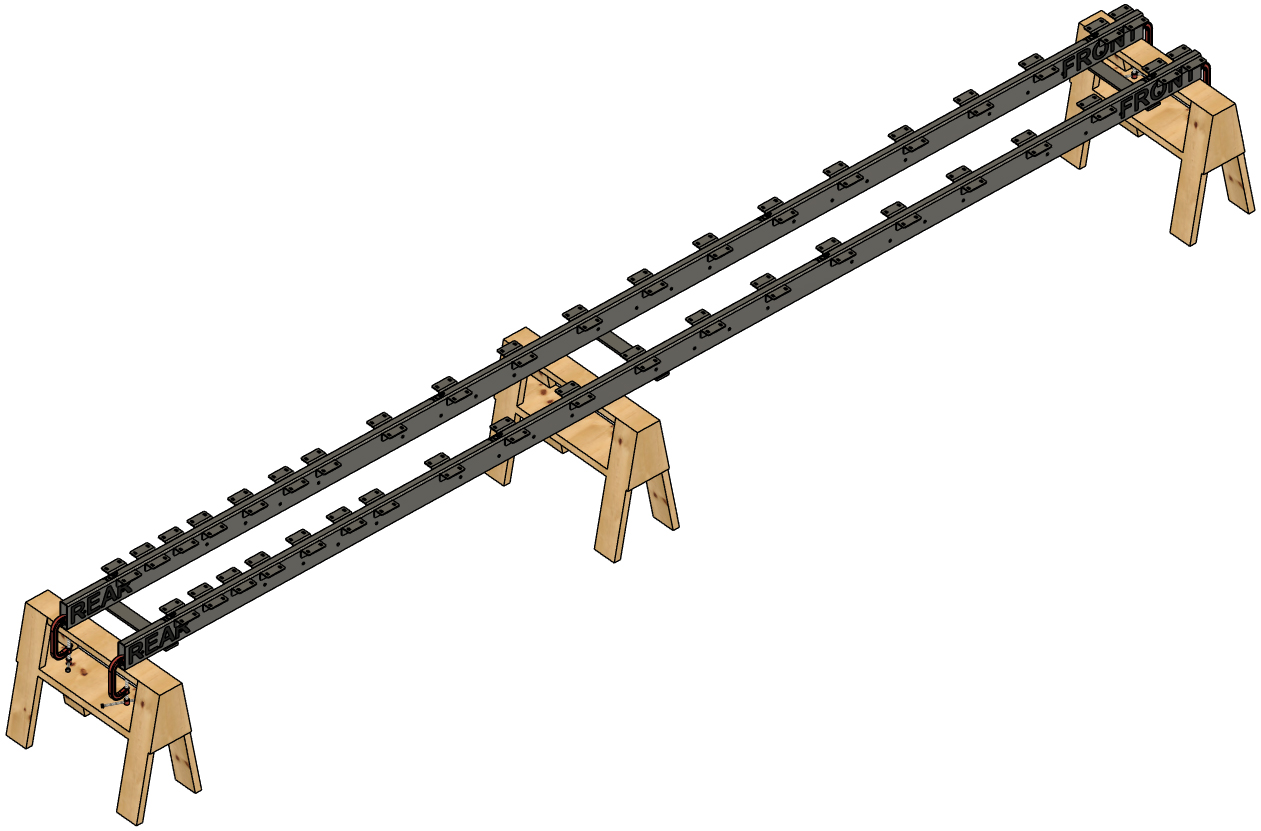

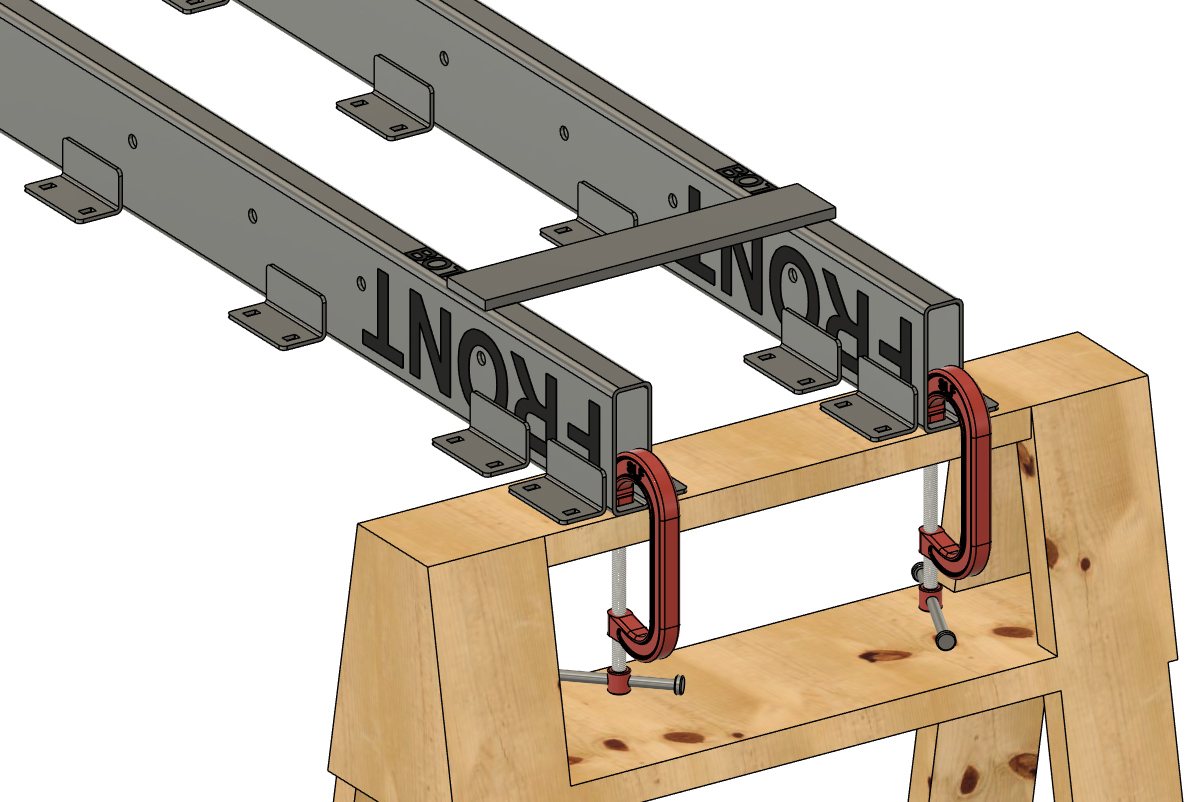

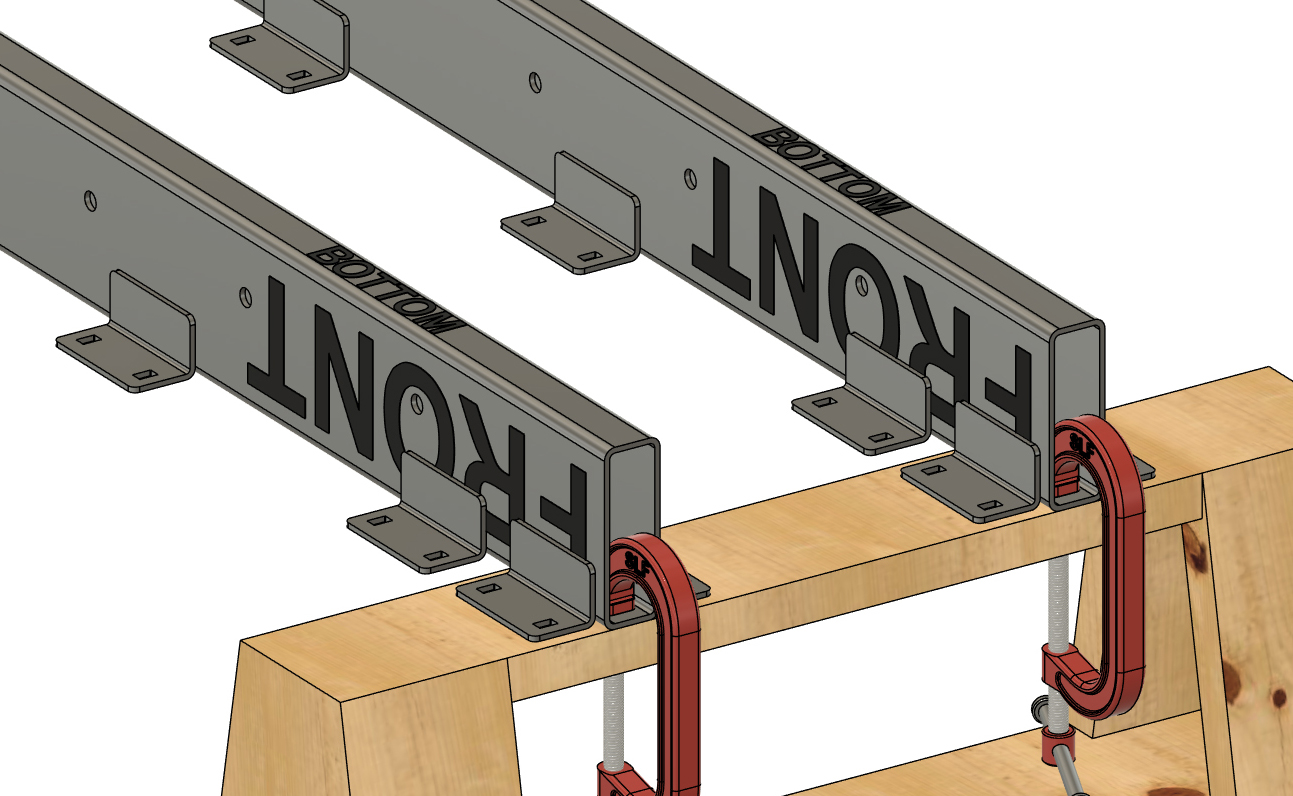

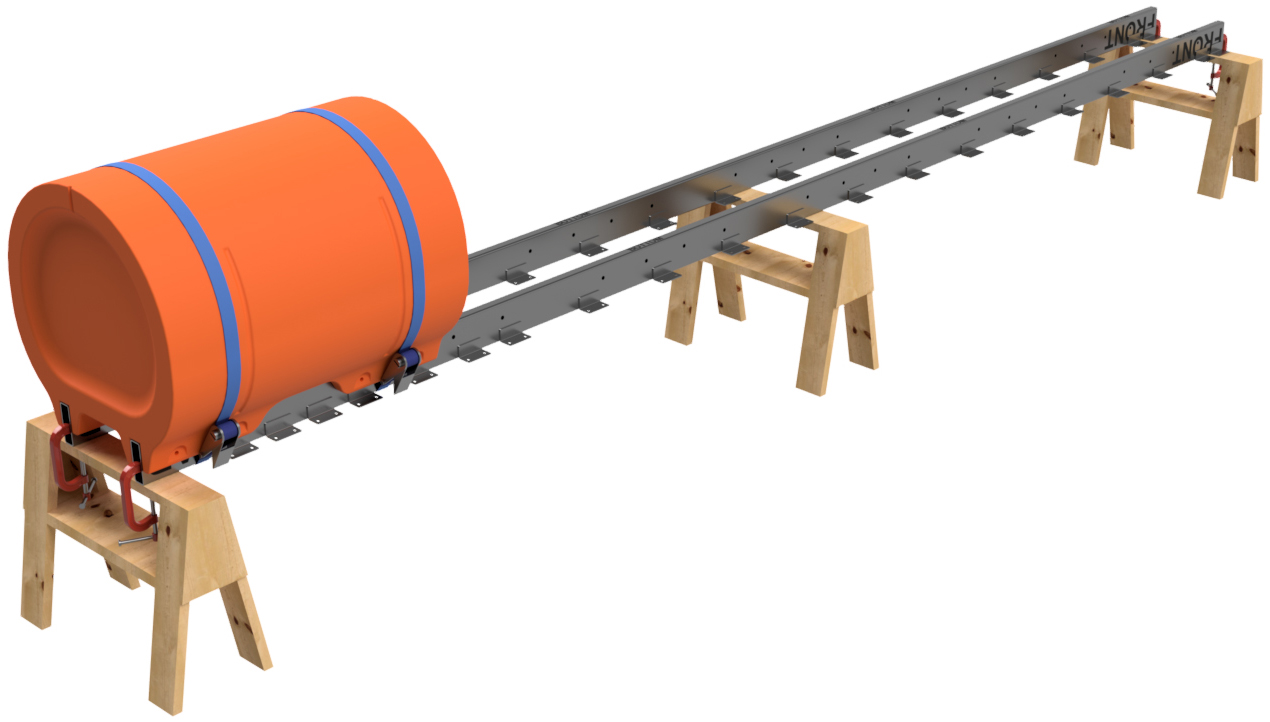

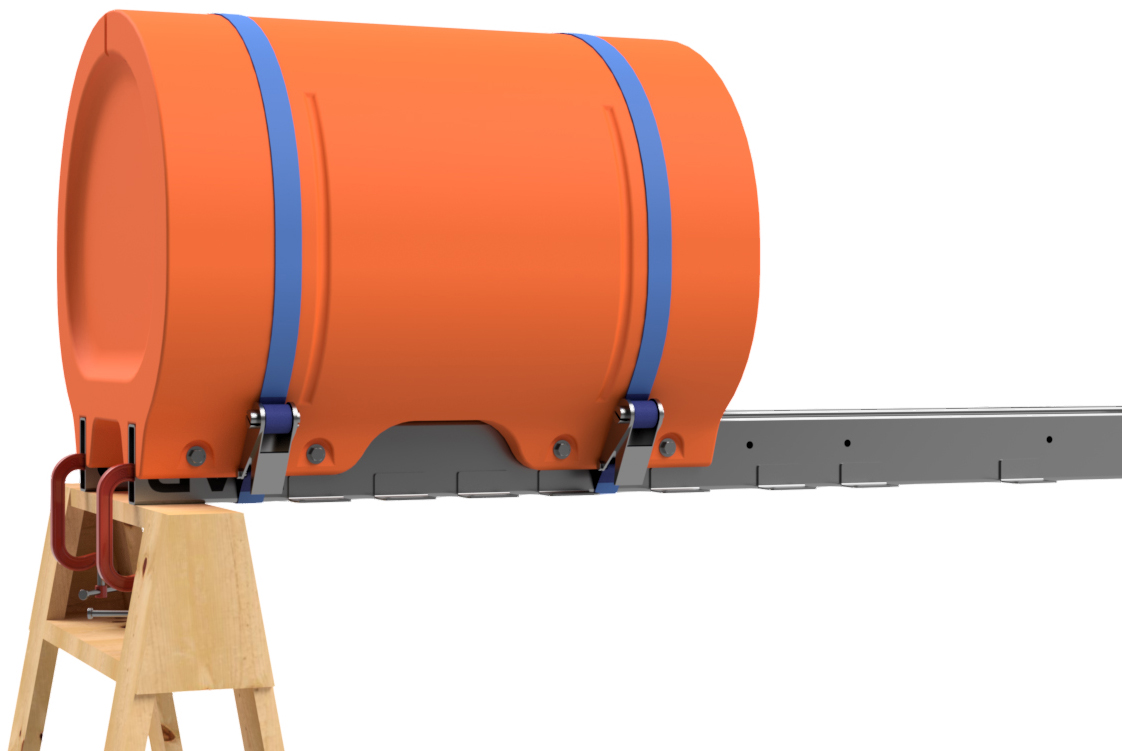

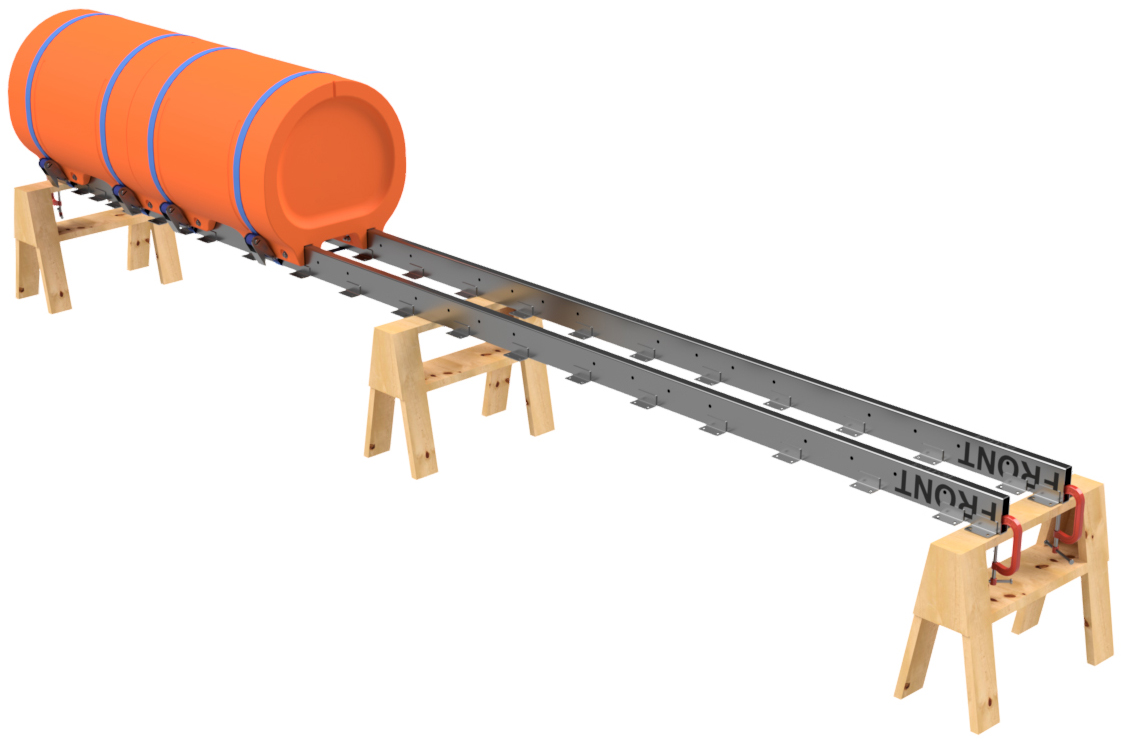

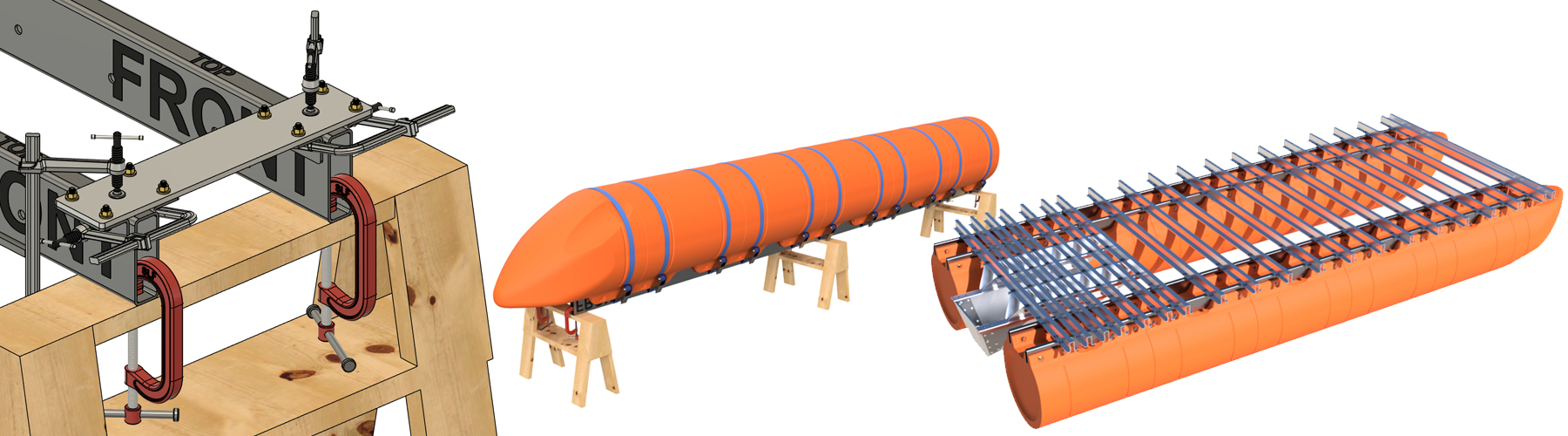

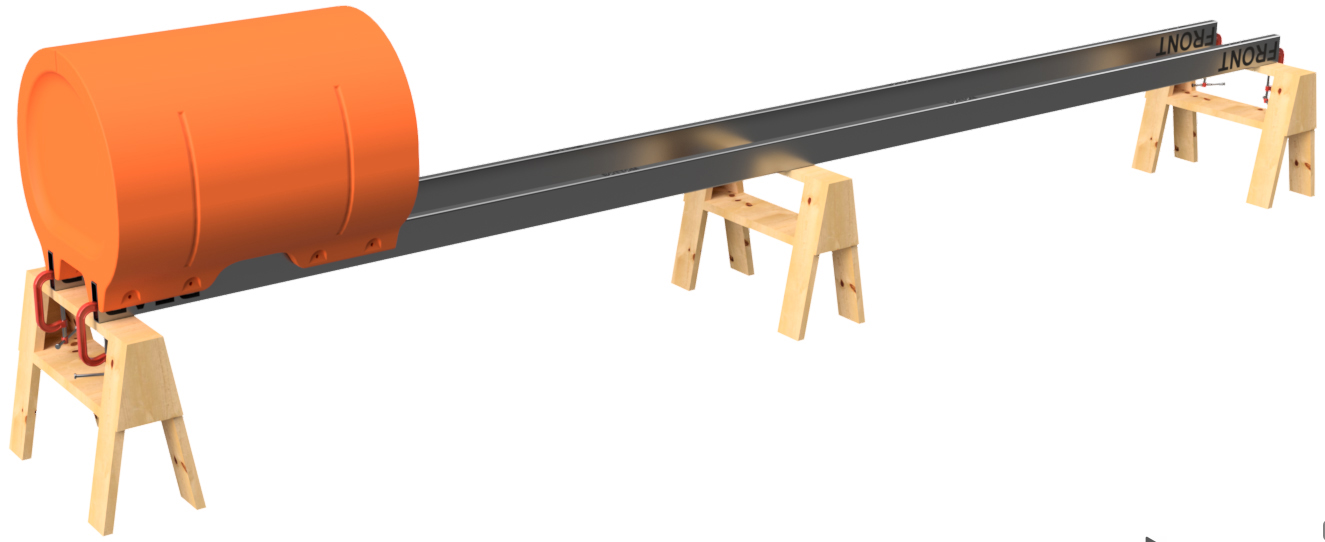

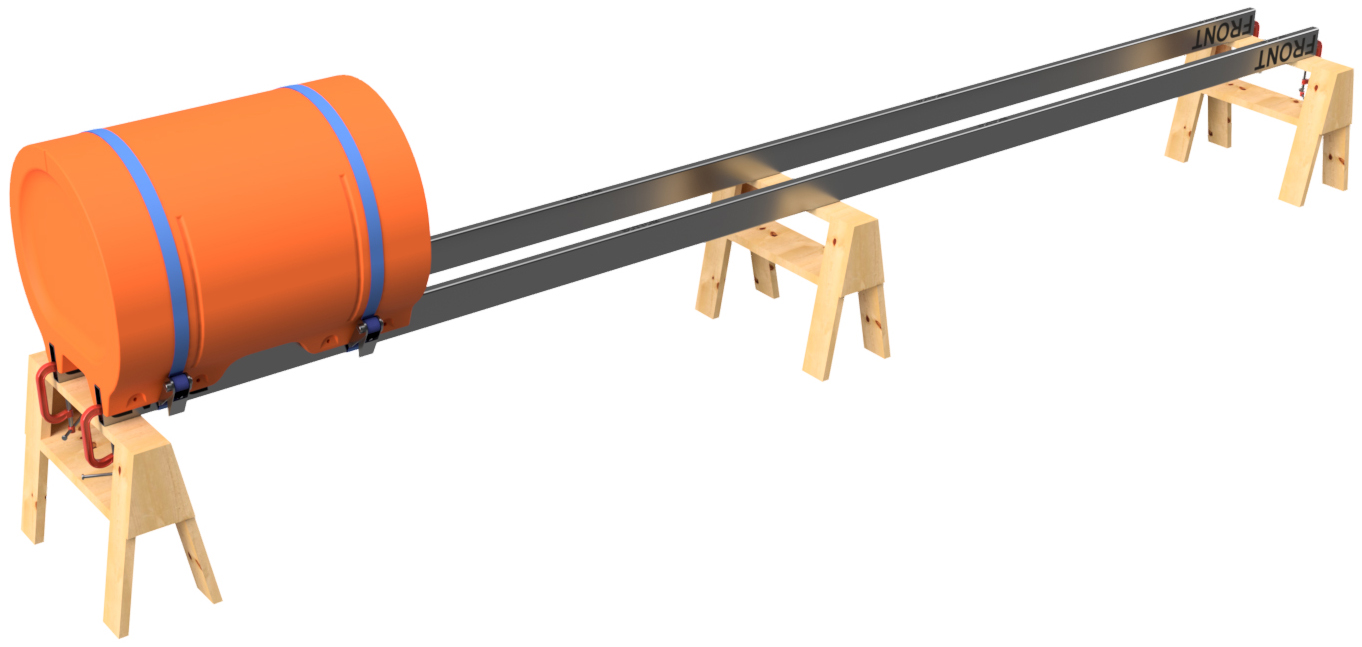

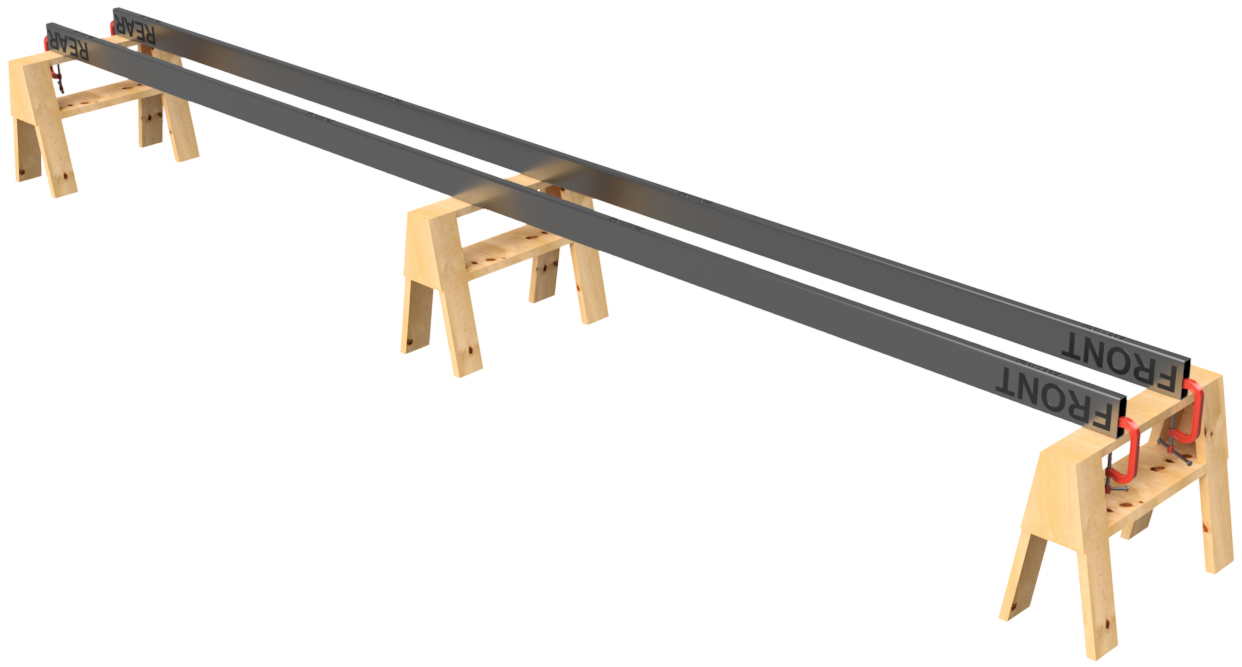

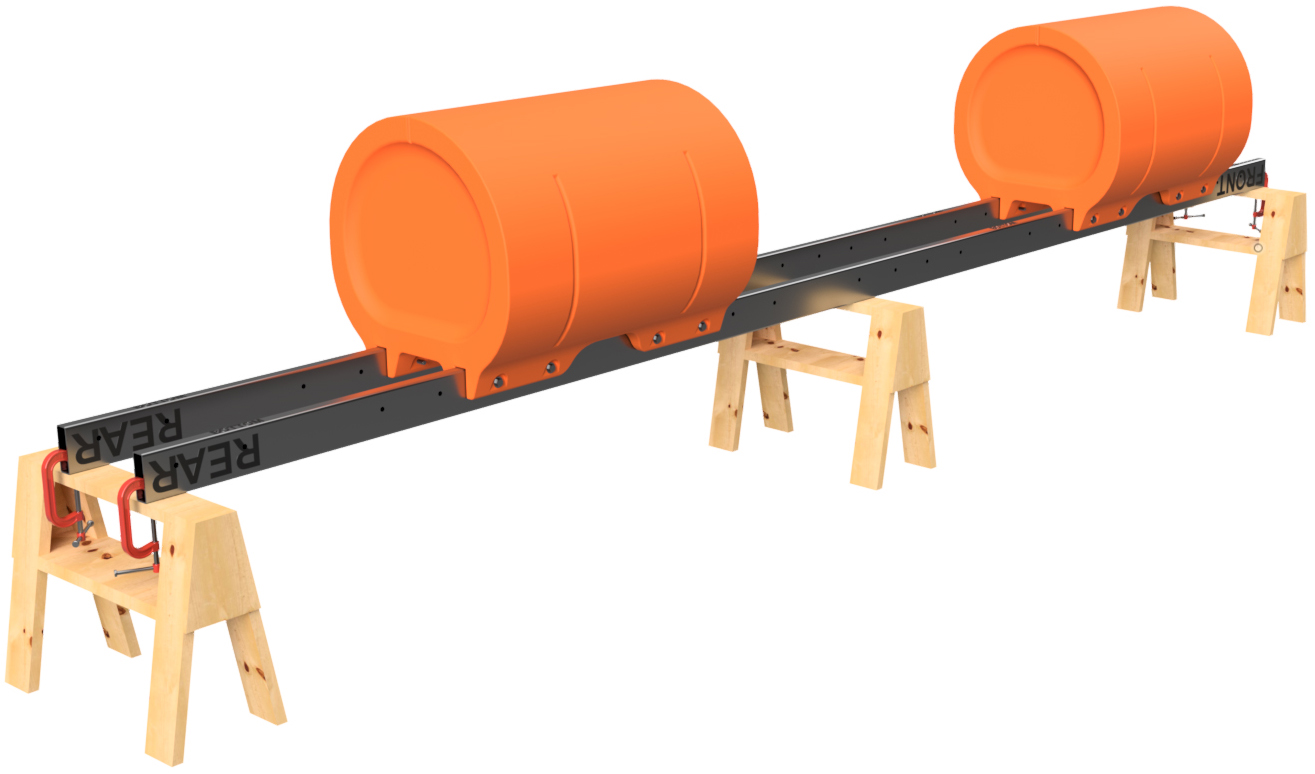

Place one of your straight floats (blunt-end floats) on the ENDS of the pair of frame tubes that are across your sawhorses. You may have to loosen the clamps on one of the 6"x2" tubes. Adjust the placement of the float so that the end is even with the ends of the tubes. Use your square to ensure that the REAR ends of the tubes are still even. Fully tighten the clamps that are holding the frame tubes to the saw horses.

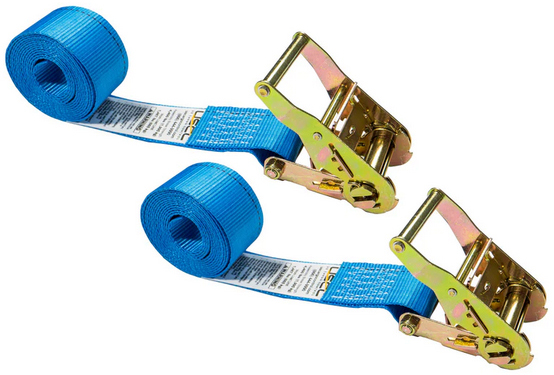

Use two ratchet straps to ensure that the float is seated onto the frame tubes. Make sure the ratchet straps are TIGHT as they will be holding the position of the float as we place other floats against it moving forward. When we build these barges, we prefer the 2" wide "endless" ratchet straps from US Cargo Control. We use their 15' long straps for this. You will require straps no shorter than 12' ratchet straps for this operation. |

|

|

STEP 7

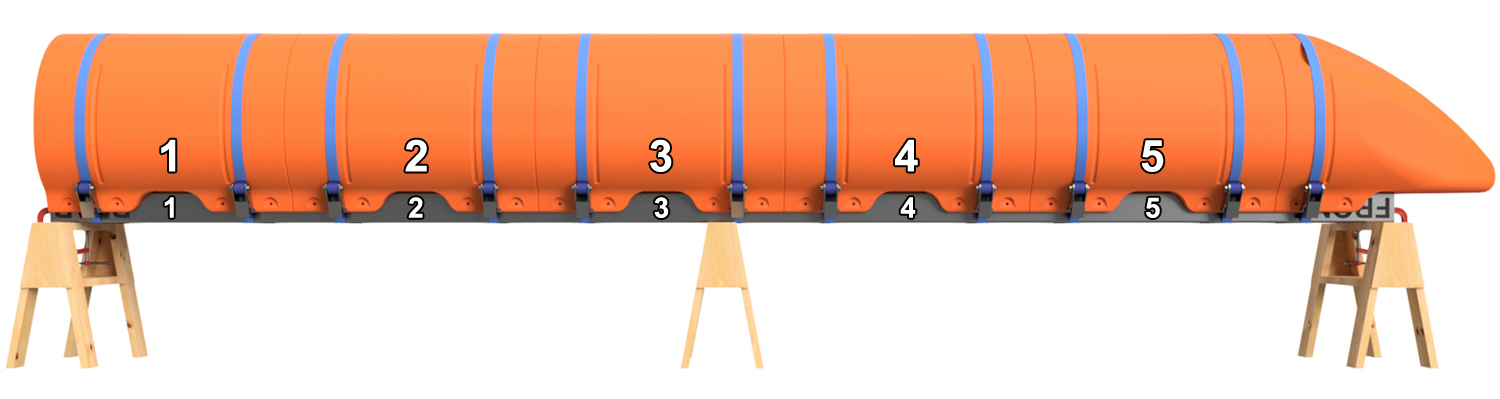

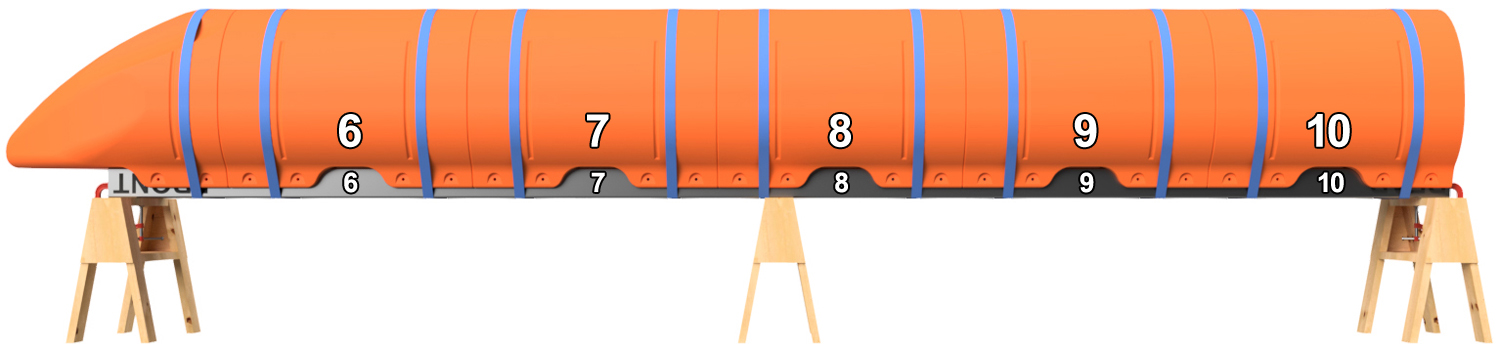

Using a marker (ink or paint), number the positions of the straight floats on the frame tubes as shown. Do this on both sides of the pontoon assembly. For instance, if you're building a 20' long pontoon, you'll want to label position 1, 2, 3, 4, and 5 on one side and 6, 7, 8, 9, and 10 on the other. This ensures that you don't mix up the positions of the floats after you drill holes. You can number the nose cone poisition if you'd like, but it will only fit in one position anyhow. We chose not to number the nose cone in our example pictures. You can use a piece of masking tape to write on or you can use a marker to write on the floats and frame tubes. If using a marker, lacquer paint thinner will remove the ink or paint after assembly, and the paint thinner will not hurt the plastic or the stainless steel.

Remove the ratchet straps and pull all the floats from the two frame tubes. |

|

STEP 8

Using a standard center punch, make the marks you made on the frame tubes with the transfer punch in step 5 more pronounce. This will make the holes easier to drill in the next step.

|

|

|

STEP 30

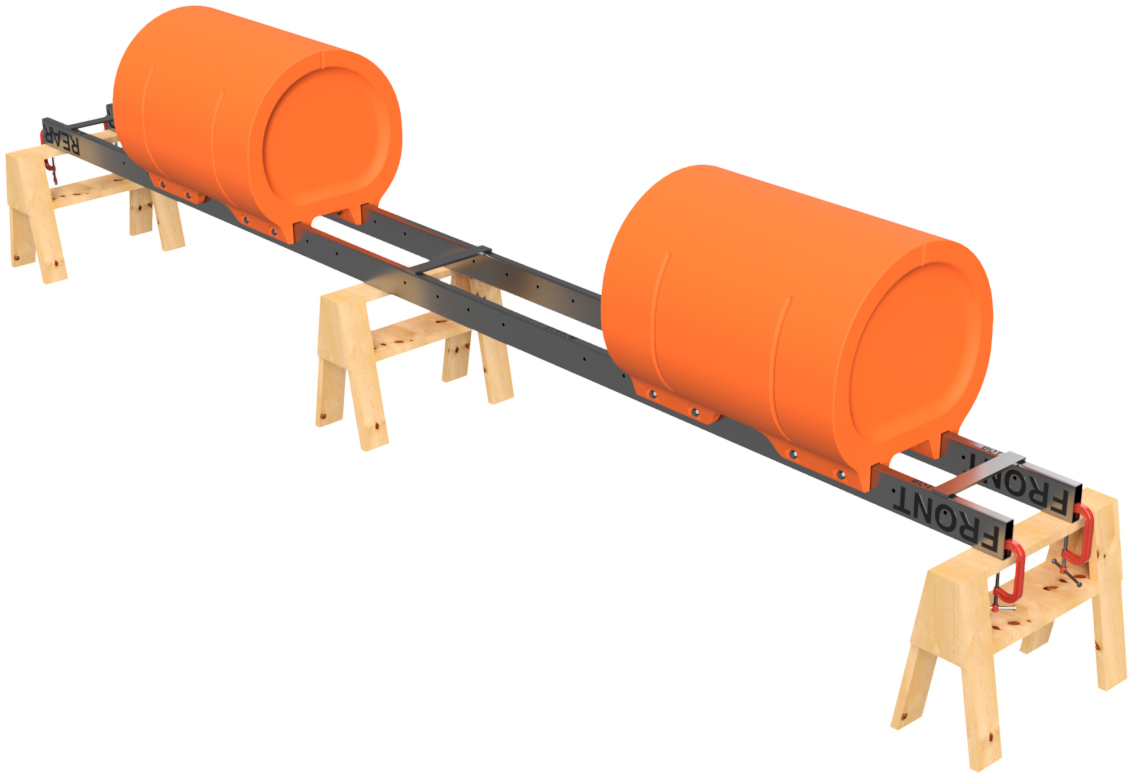

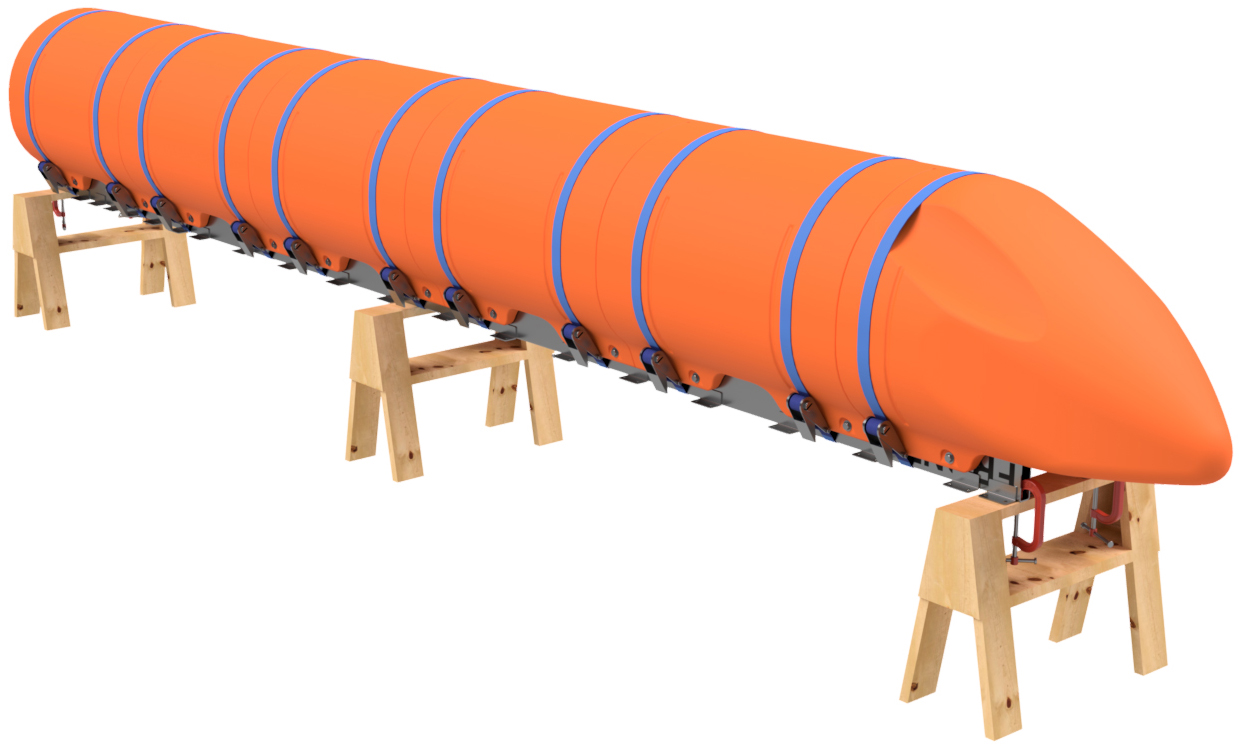

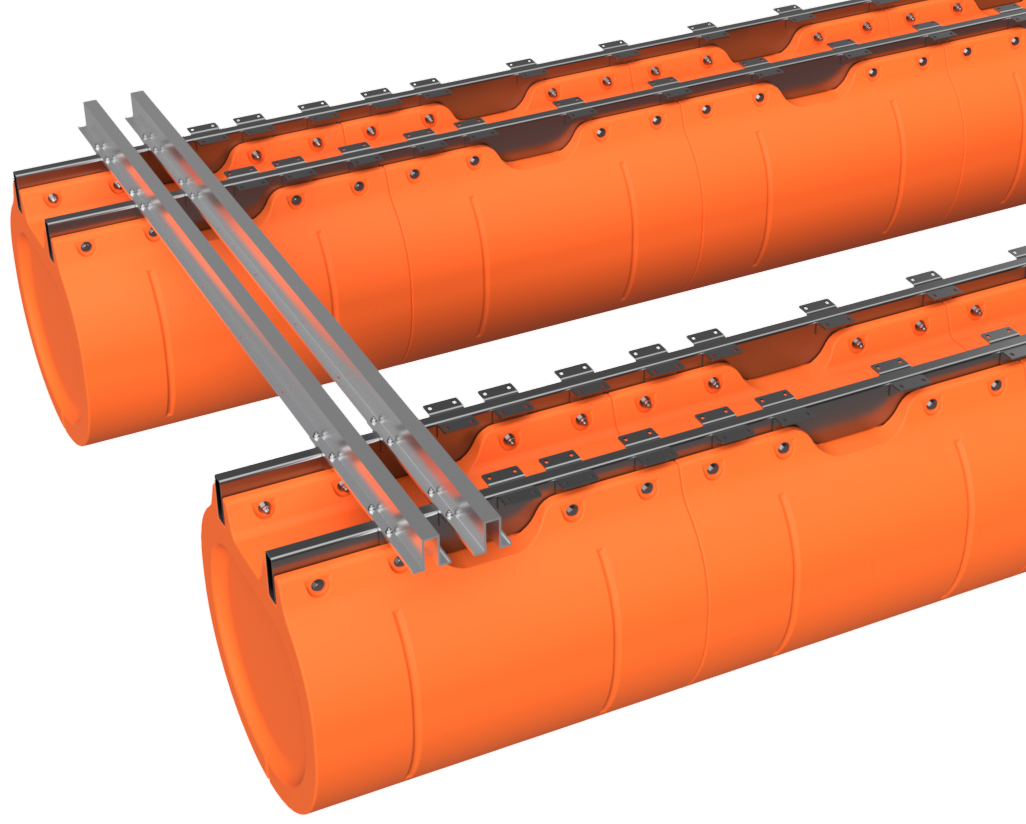

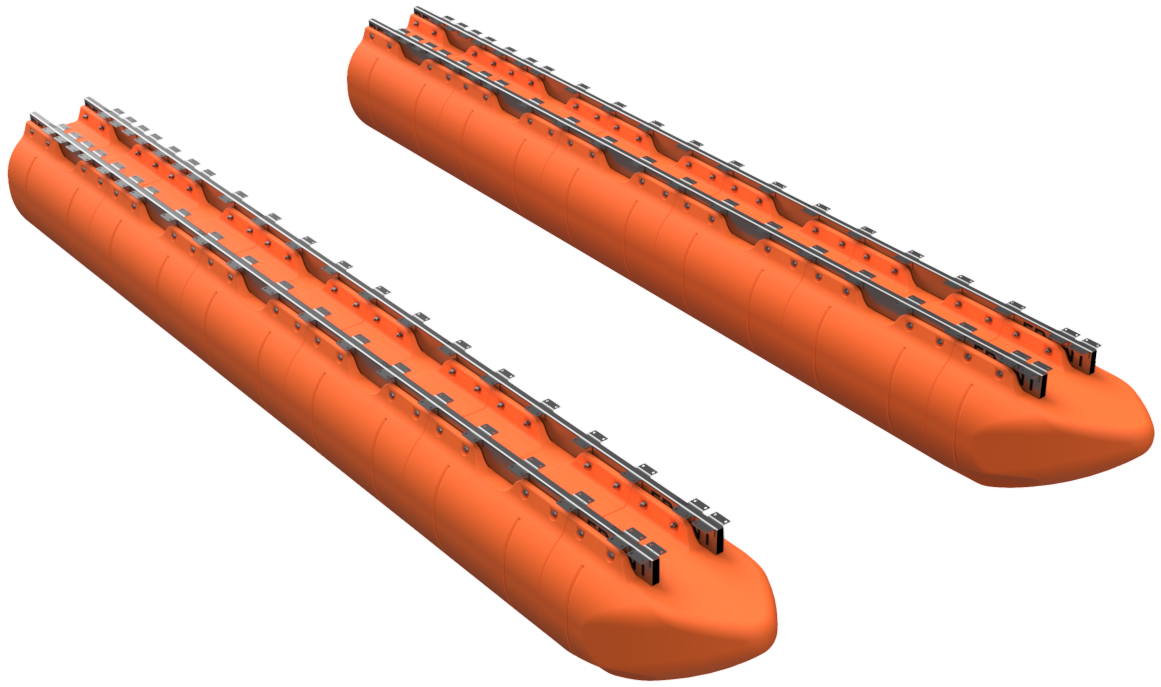

If you've reached this point, you've built at least one of your pontoon assemblies. Place your completed pontoon/pontoons aside and repeat Steps 1-29 until all of your pontoon assemblies have been built.

|

|

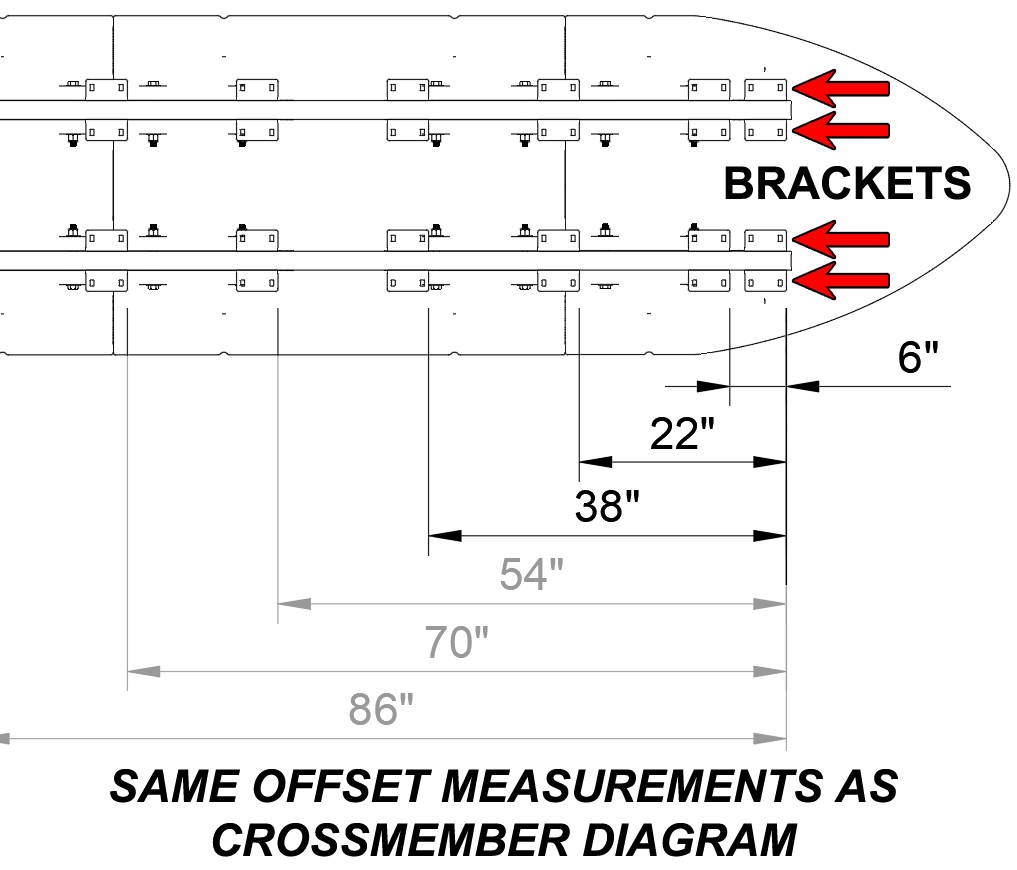

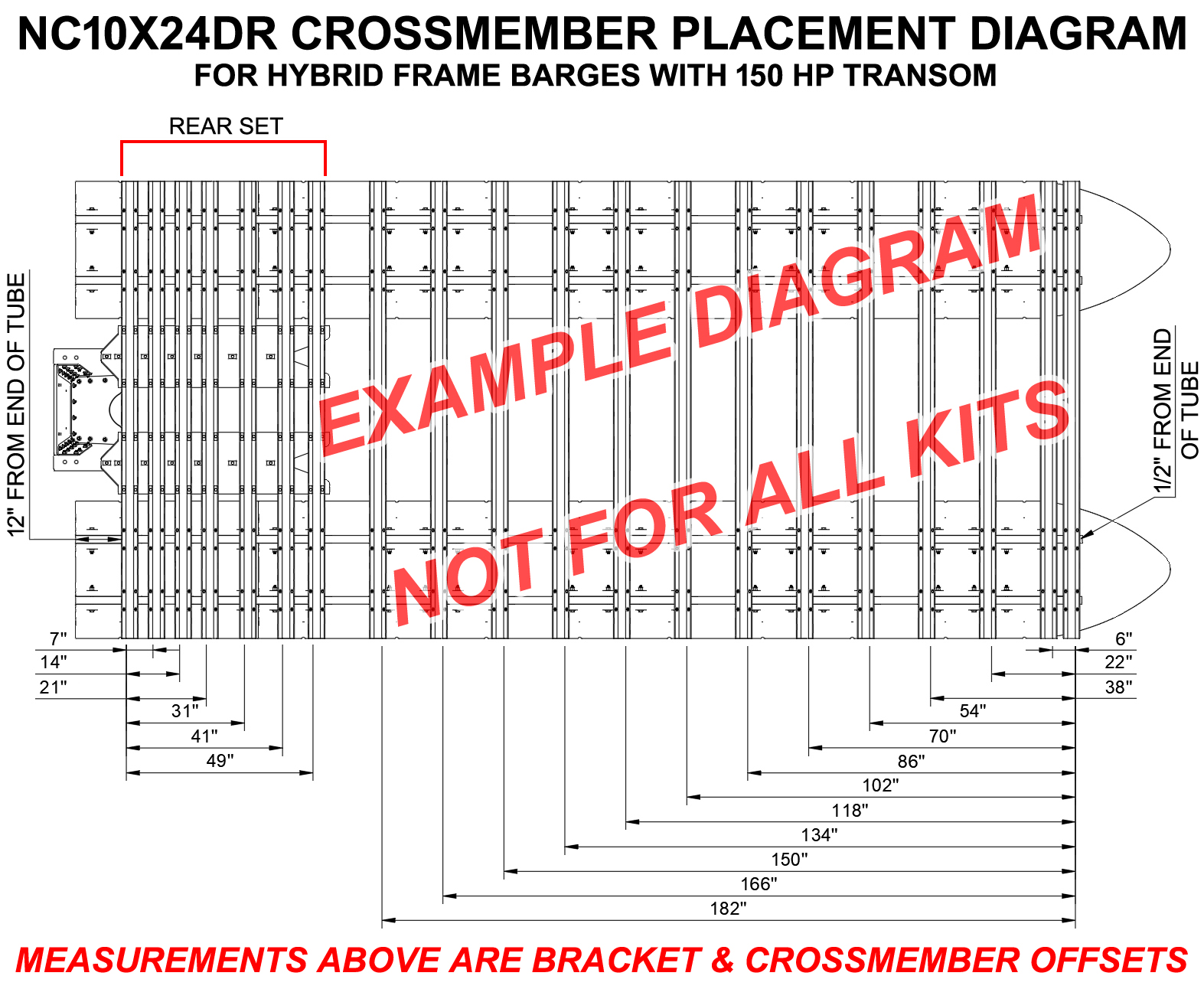

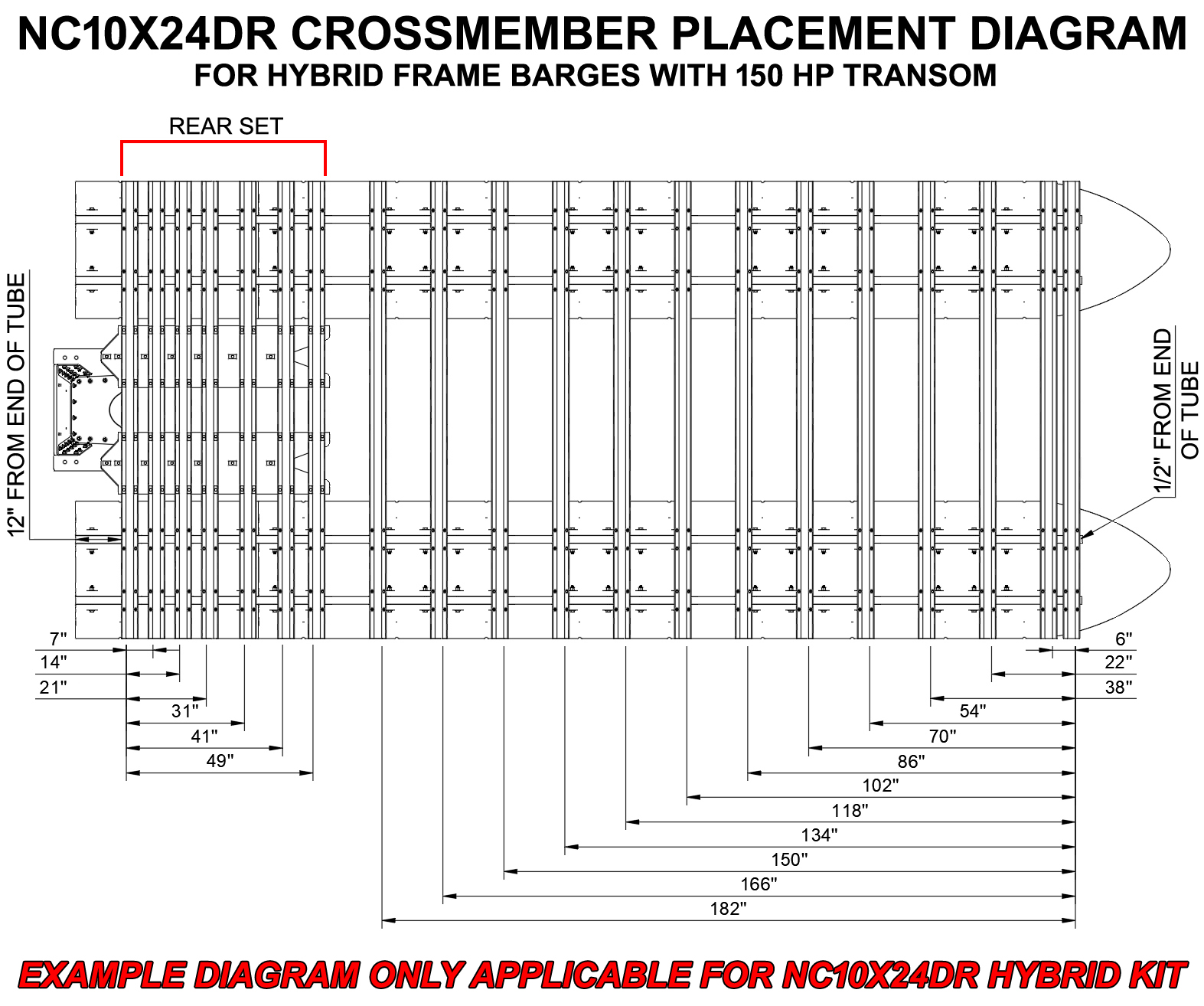

CROSSMEMBER PLACEMENT DIAGRAM NOTE #2:

The tough part of your build has been completed, so take a breath, enjoy a piece of the pizza we specified at the top of this page, and enjoy the rest of your project. The remaining part of the assembly is near impossible to mess-up!

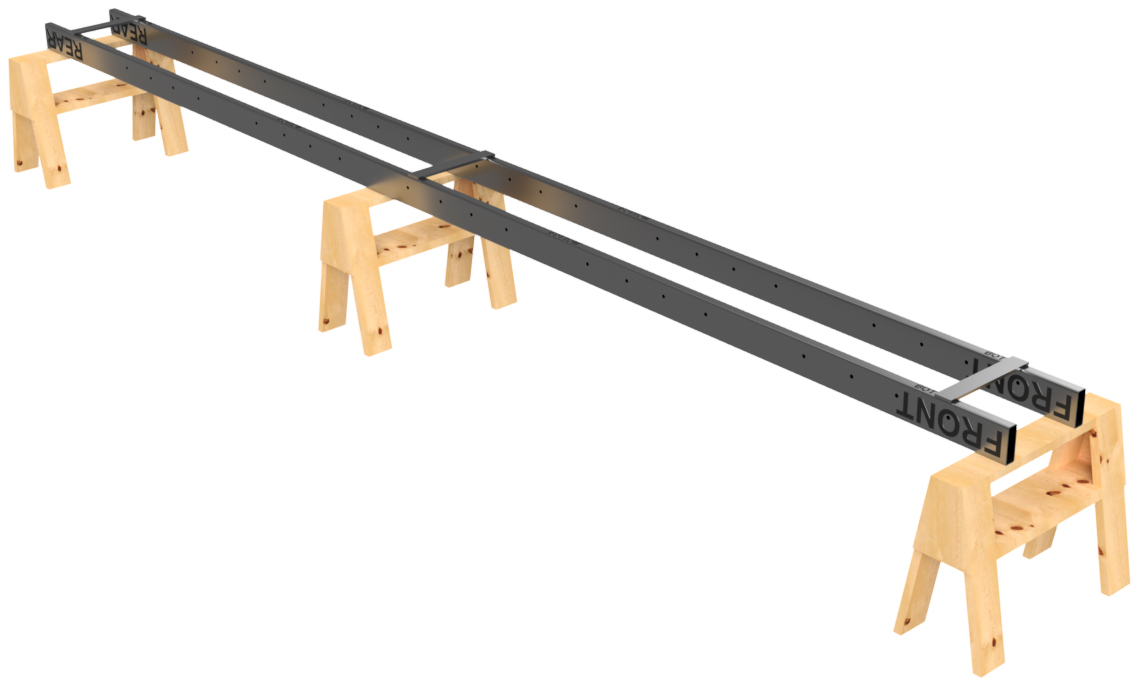

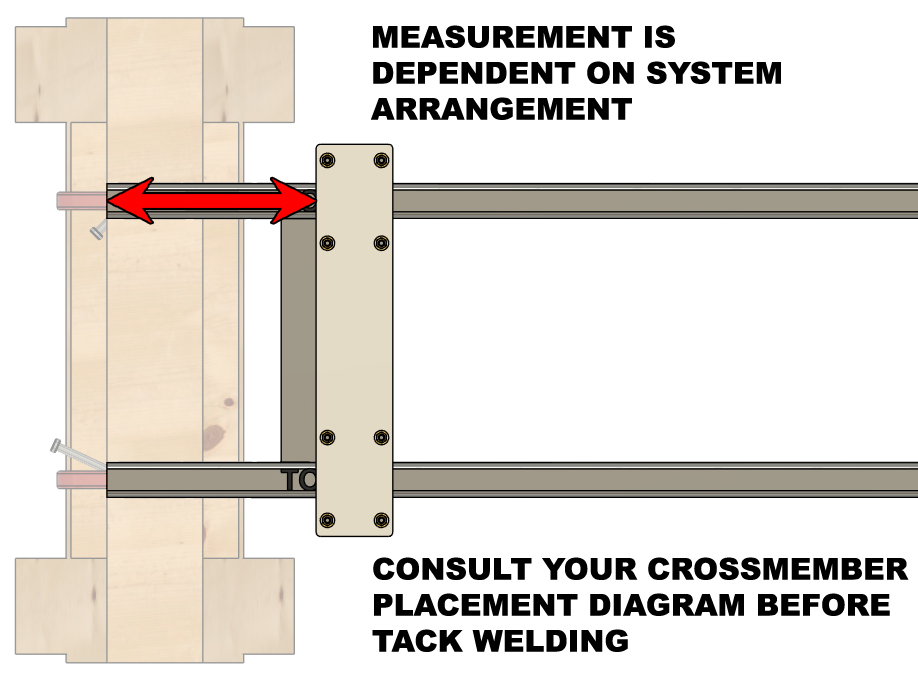

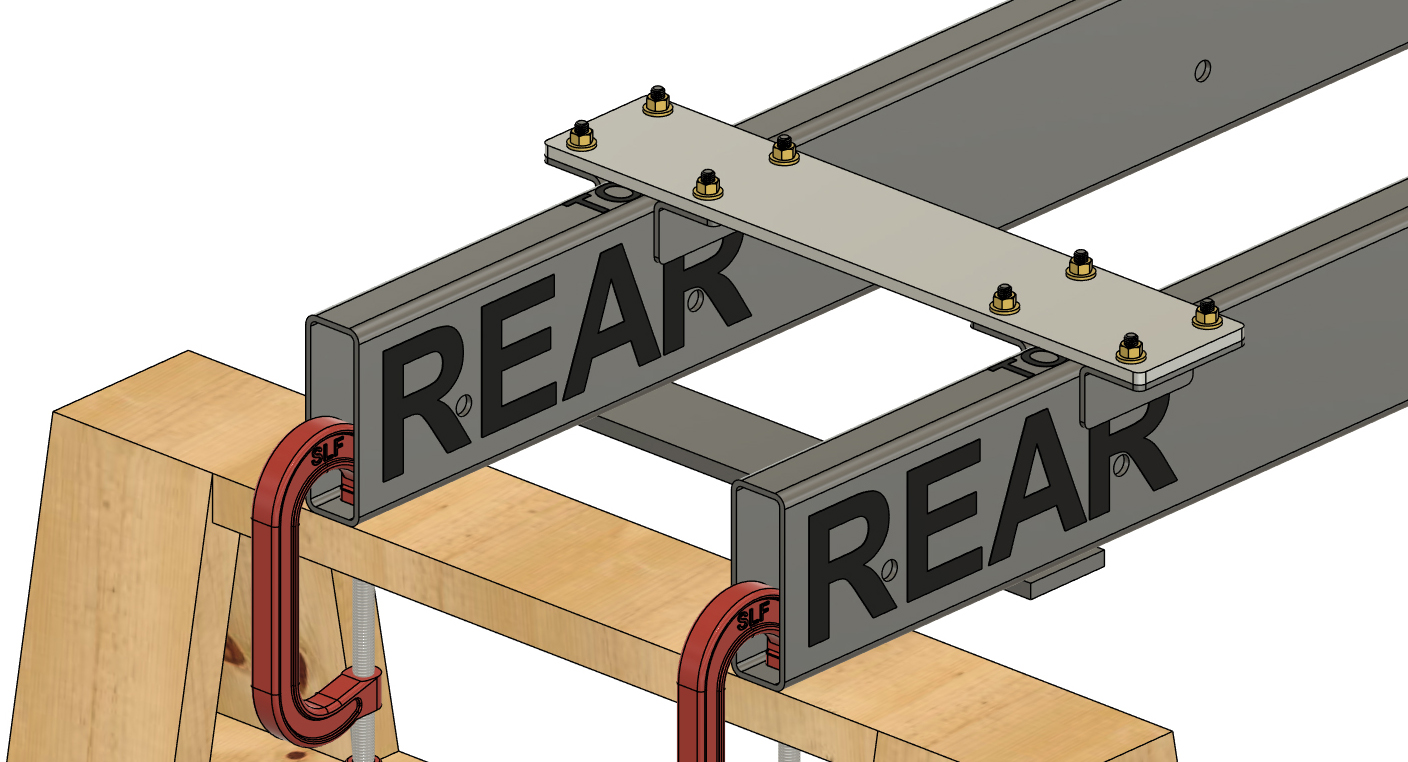

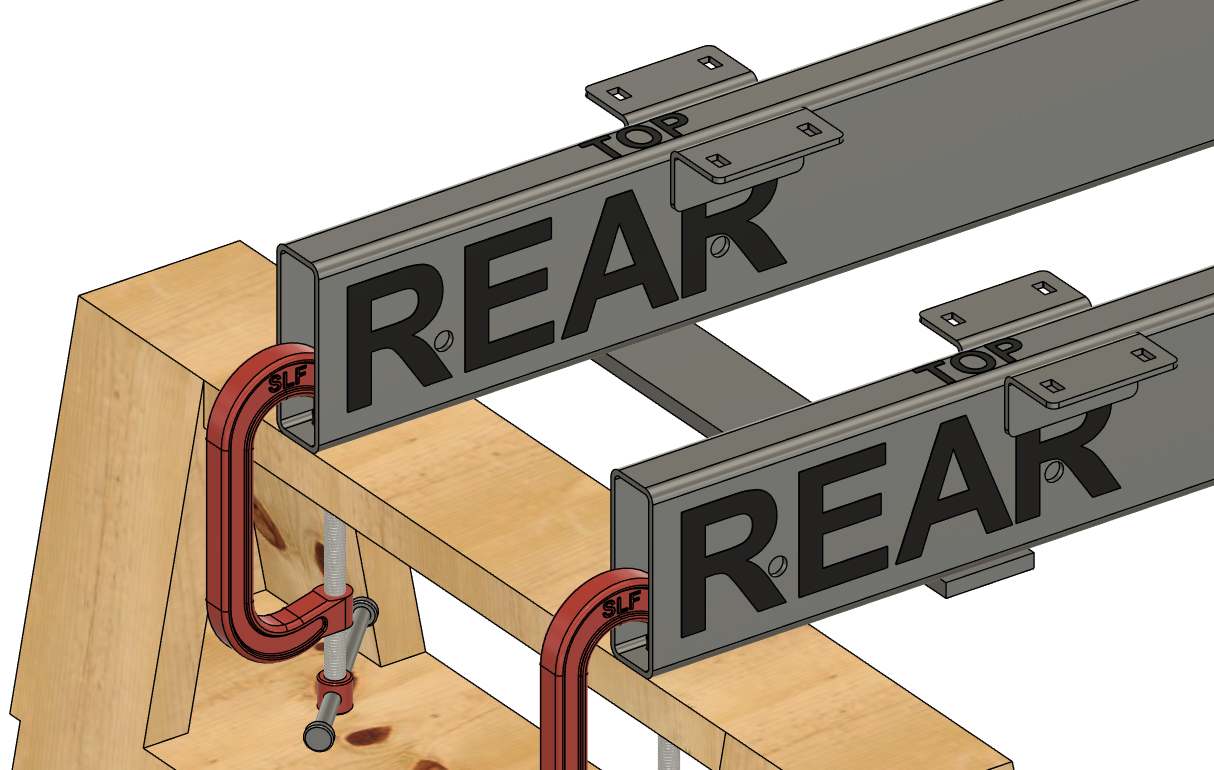

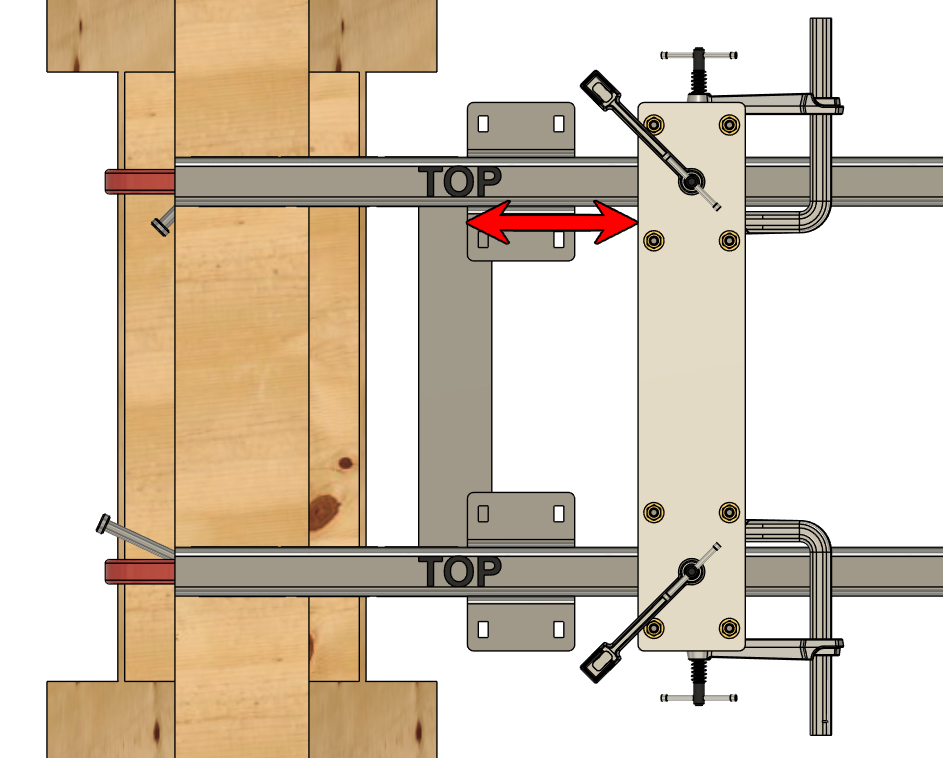

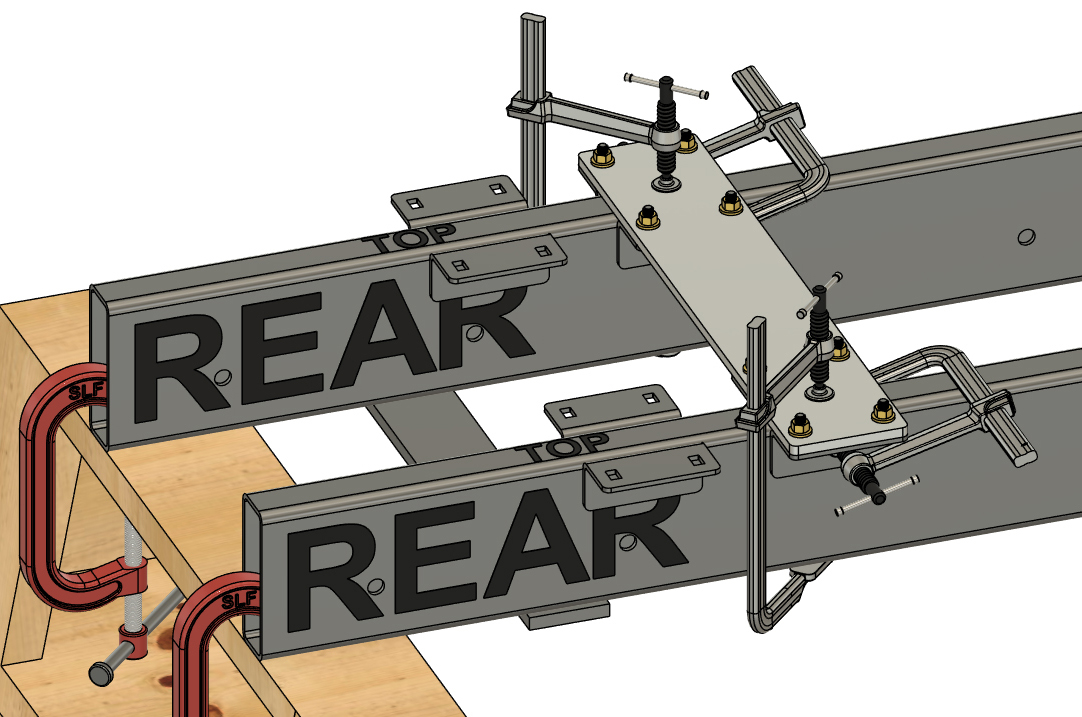

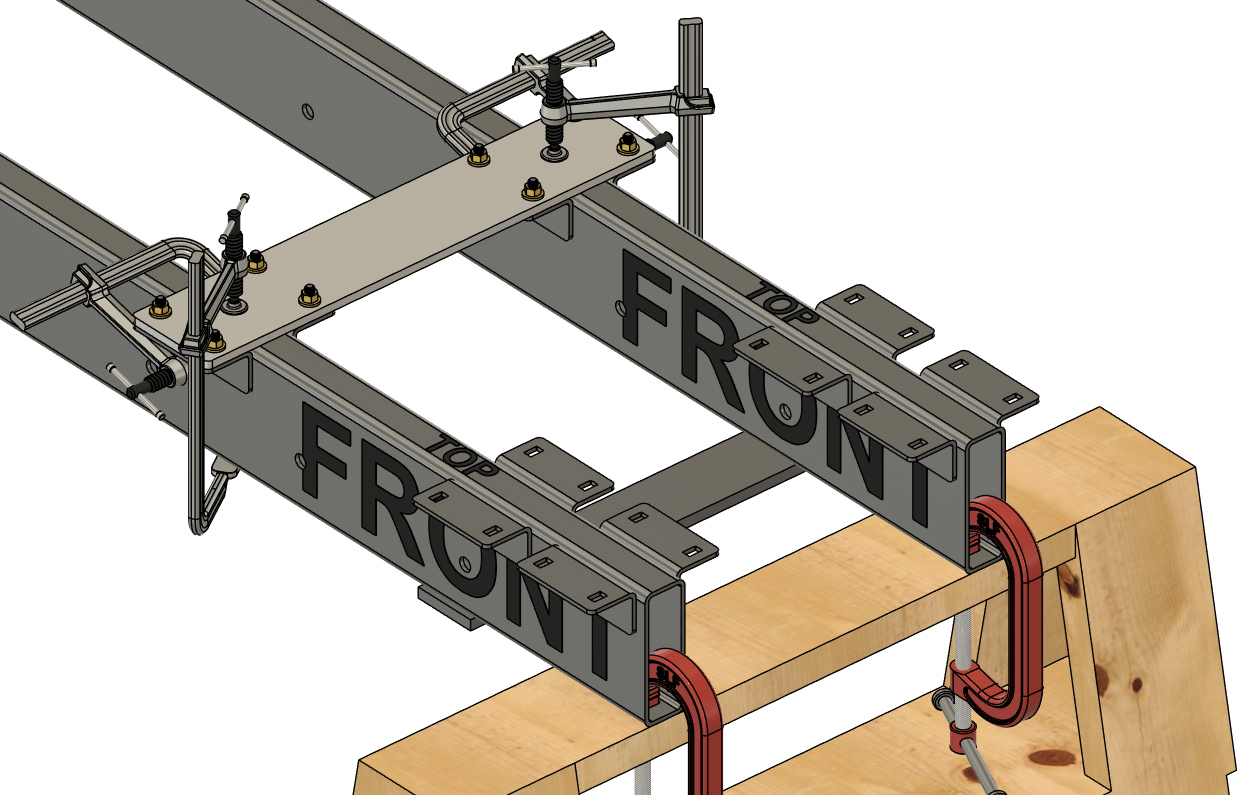

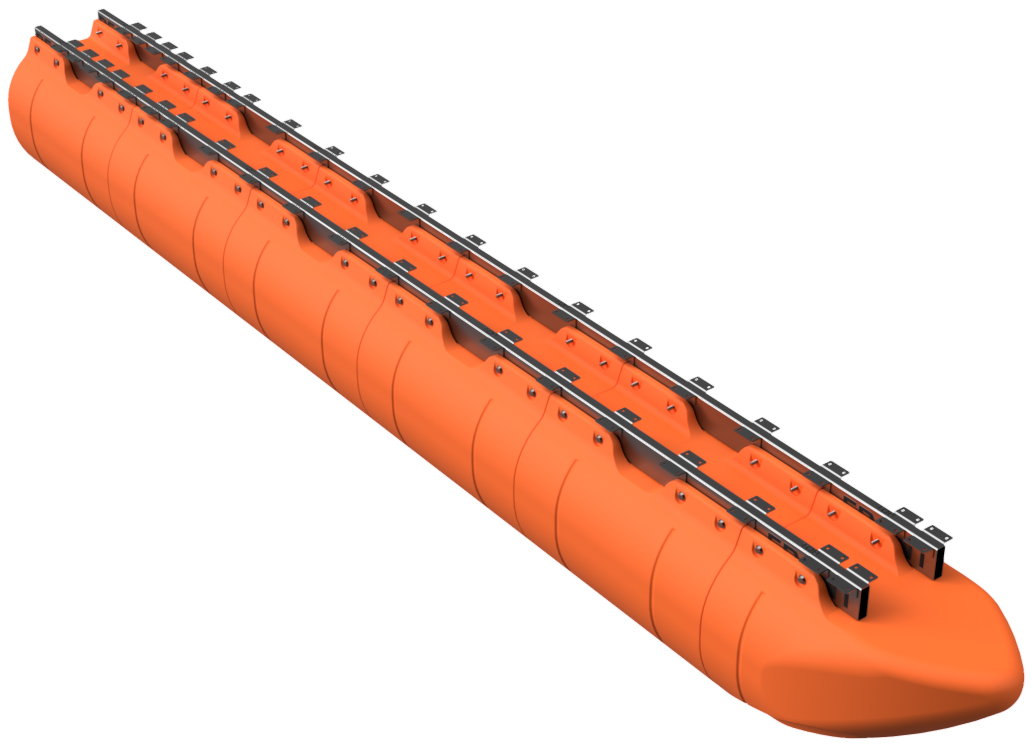

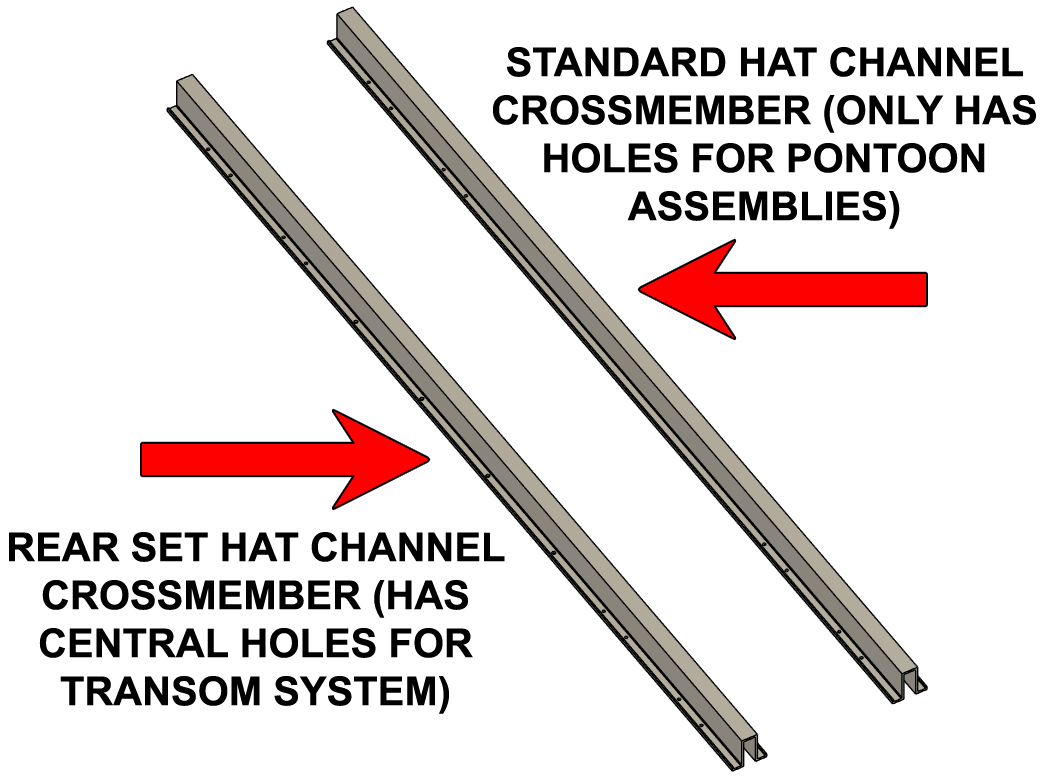

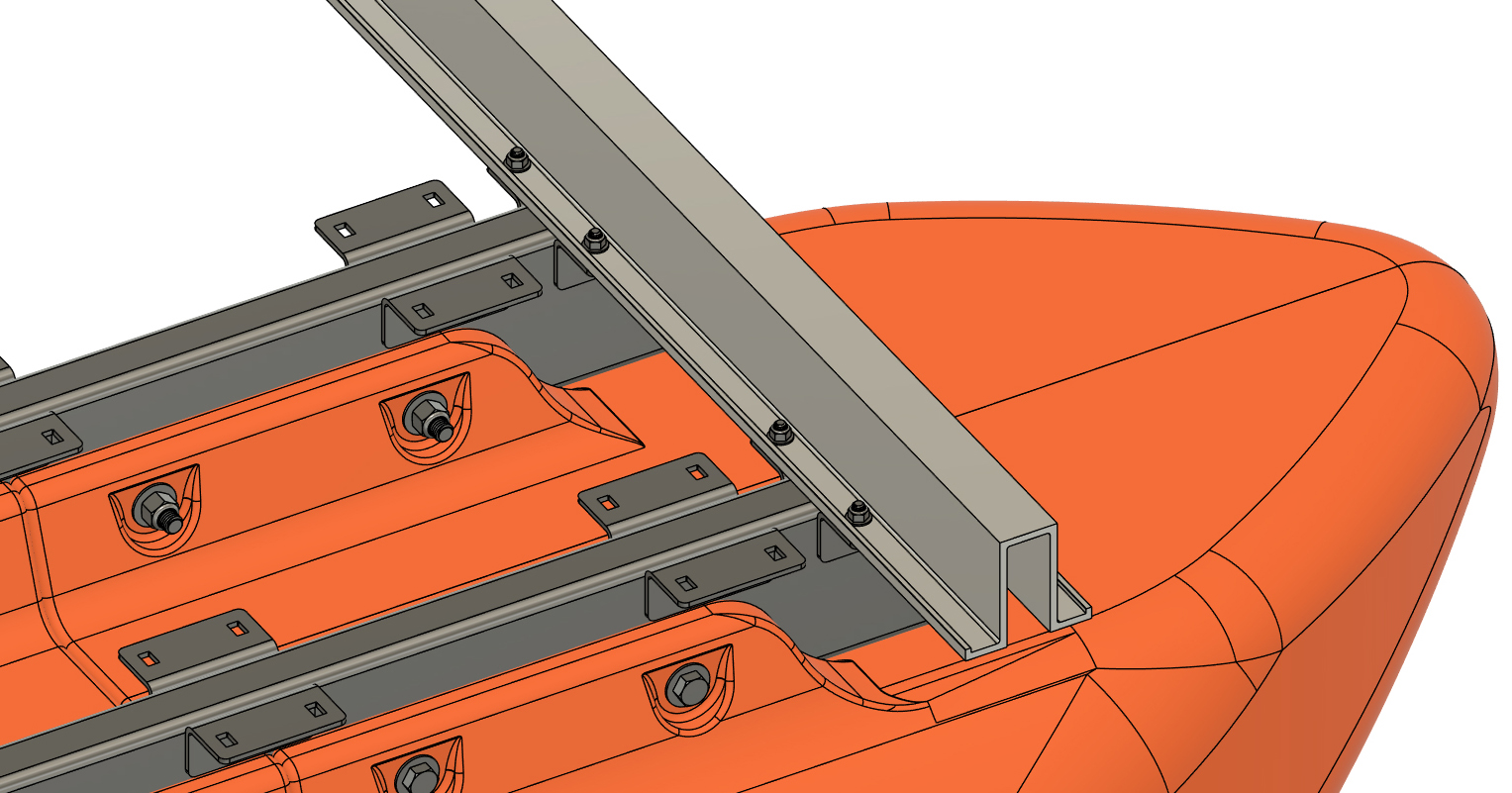

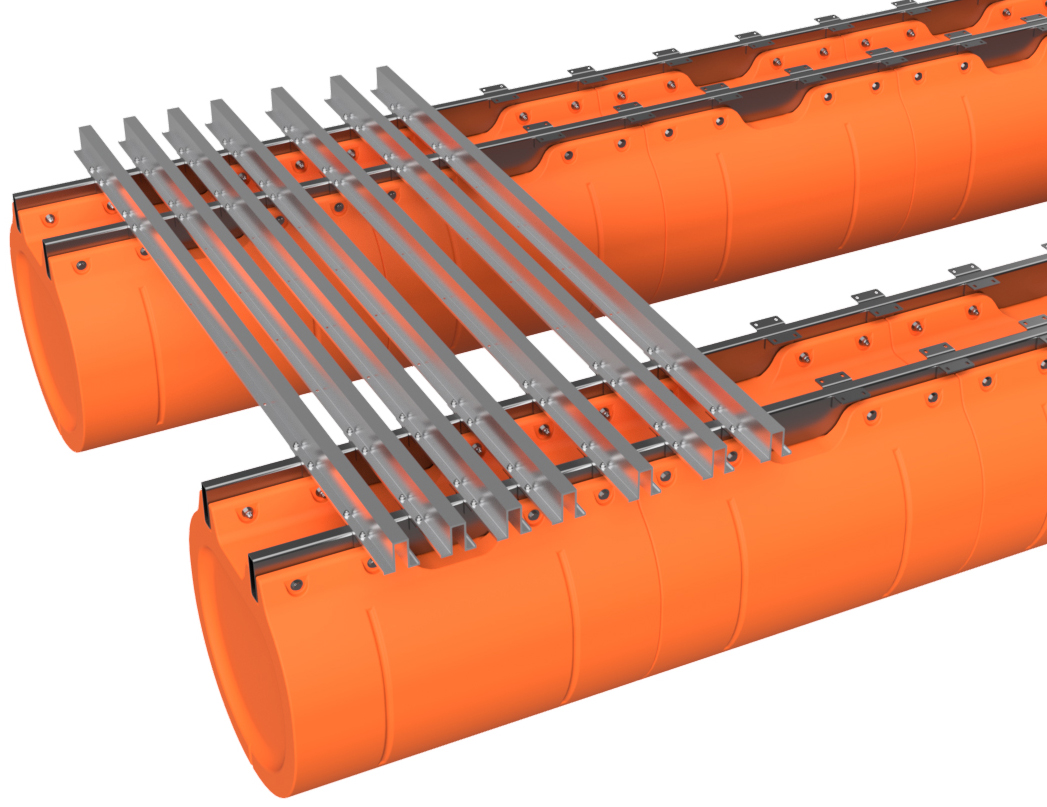

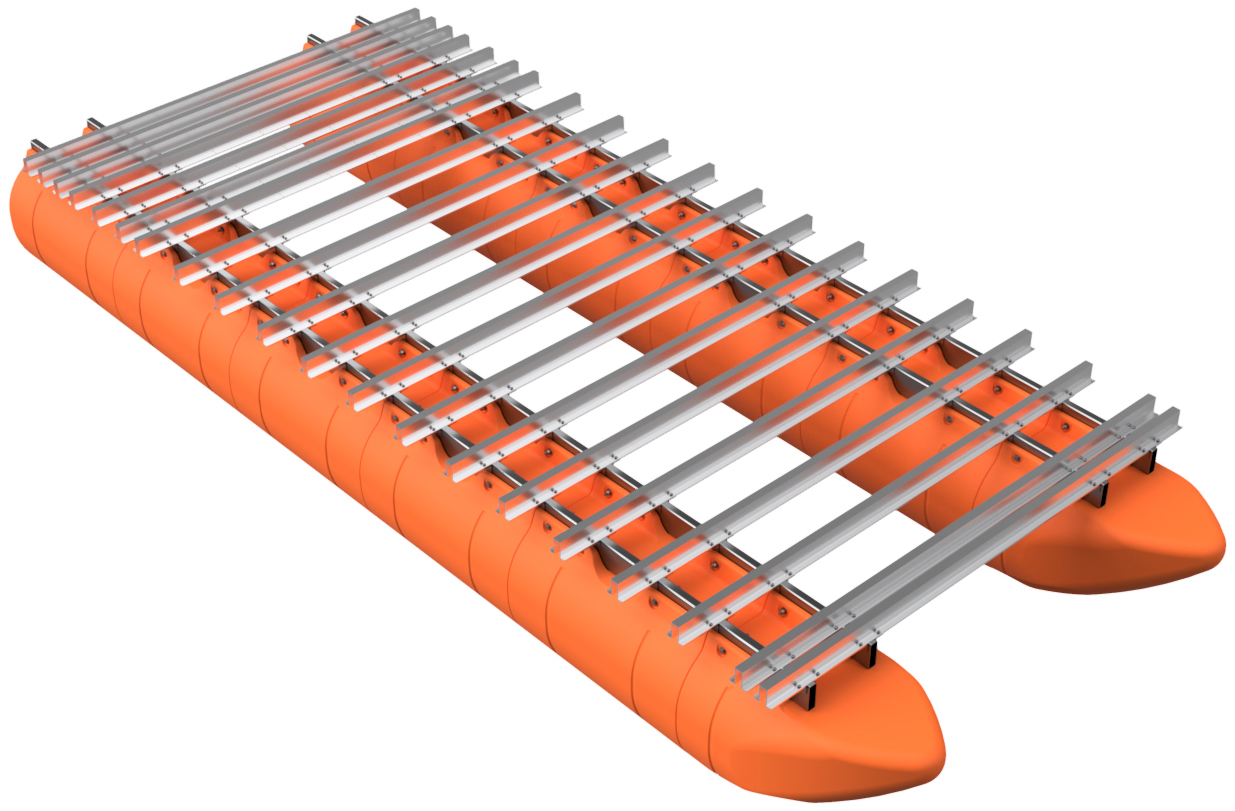

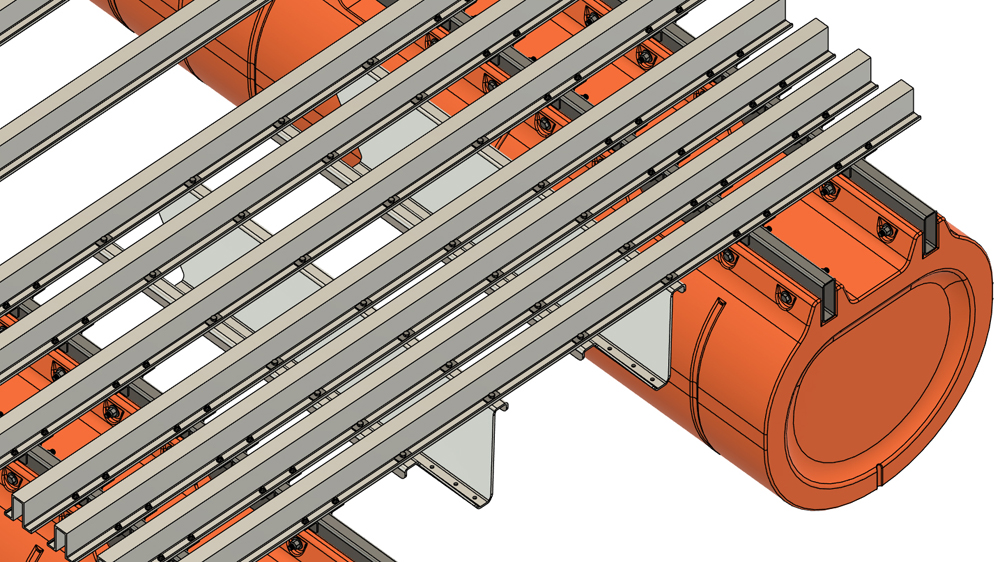

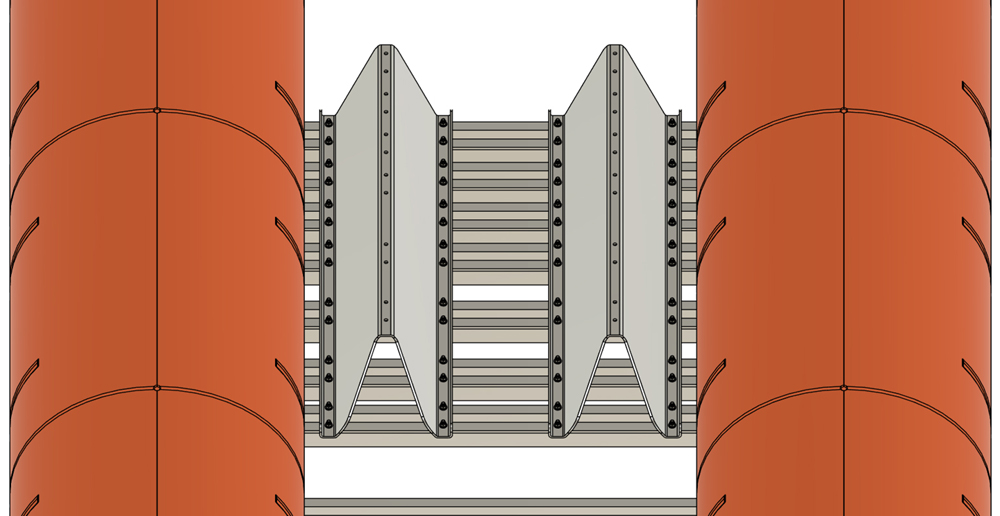

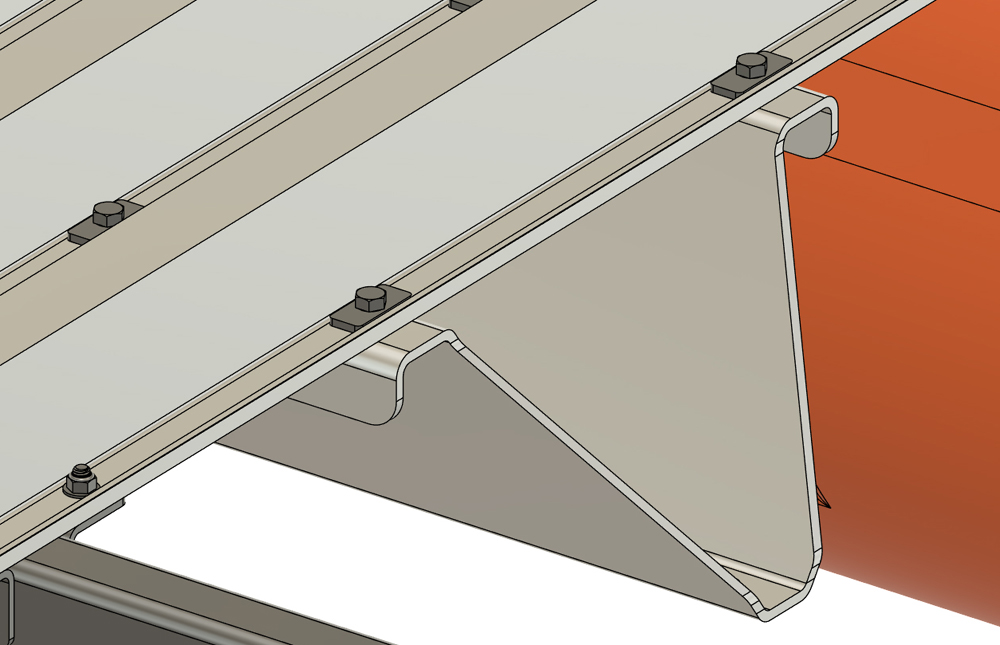

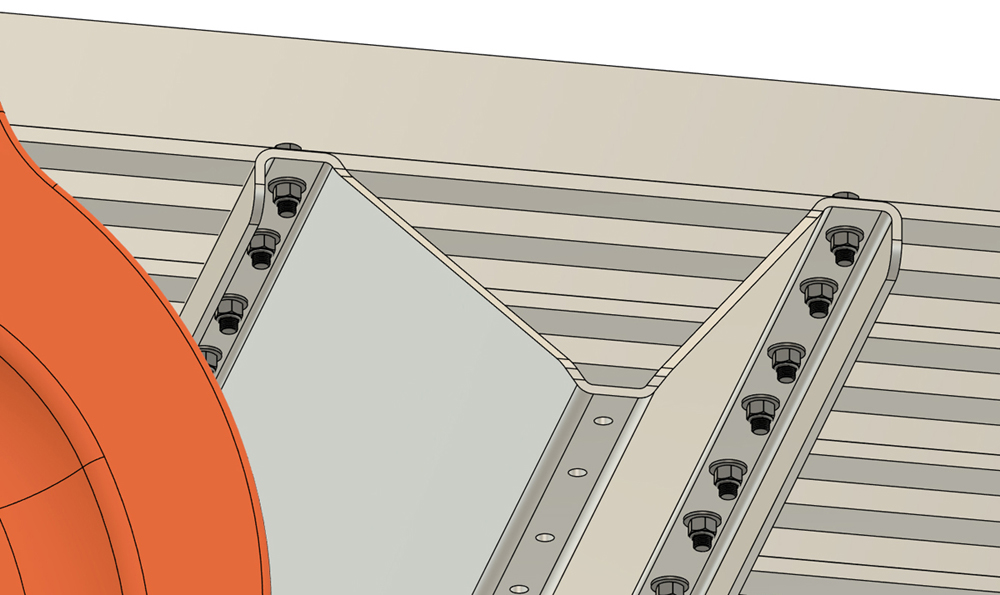

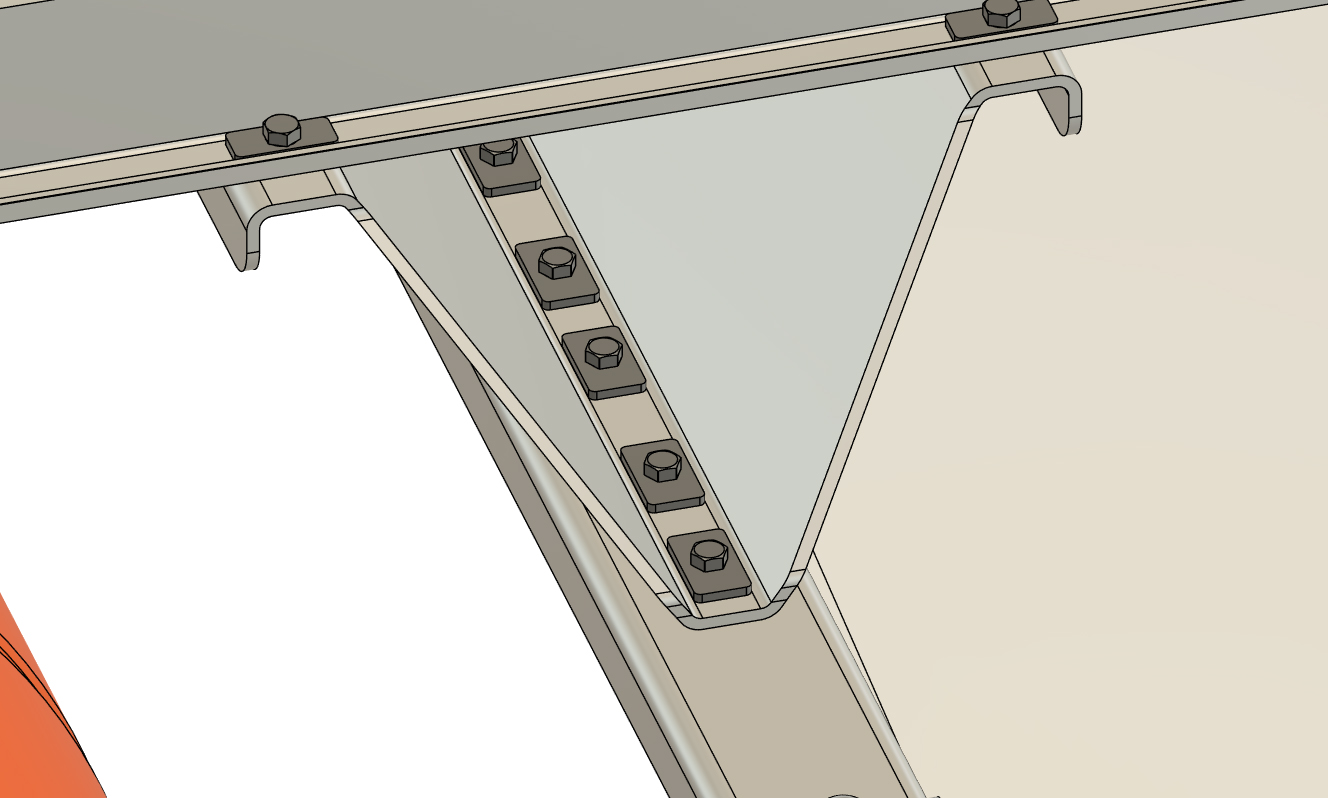

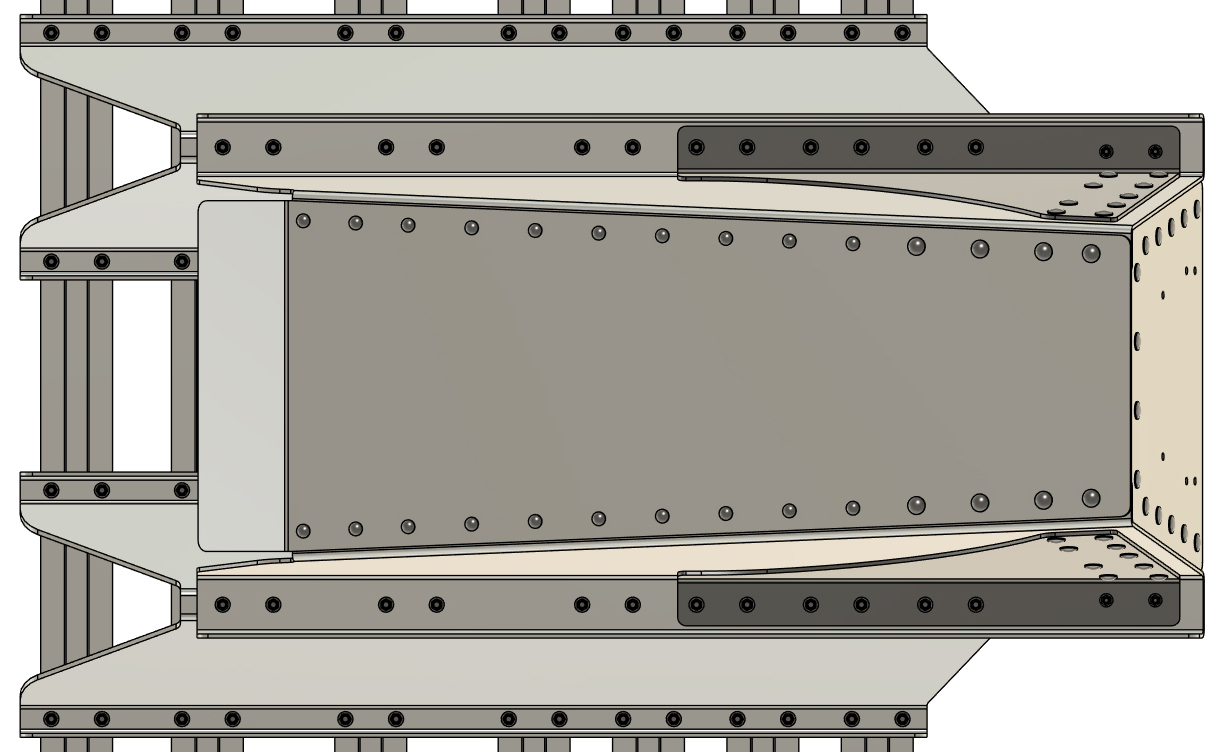

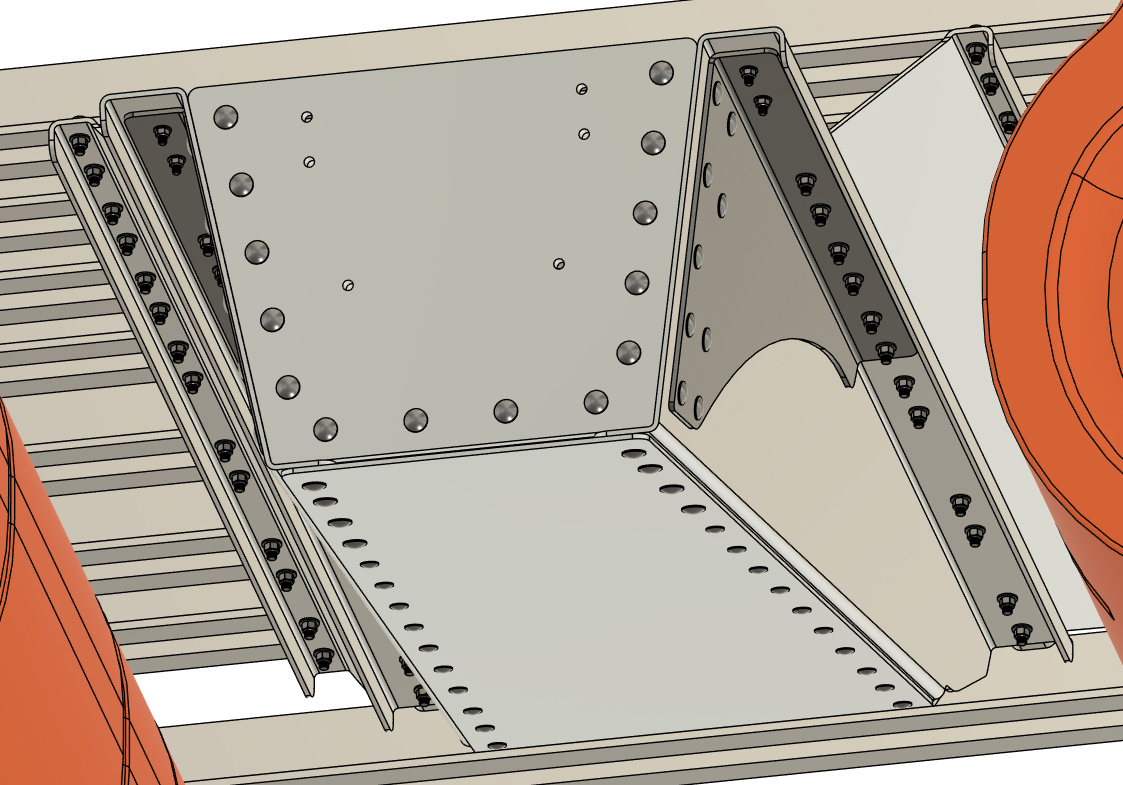

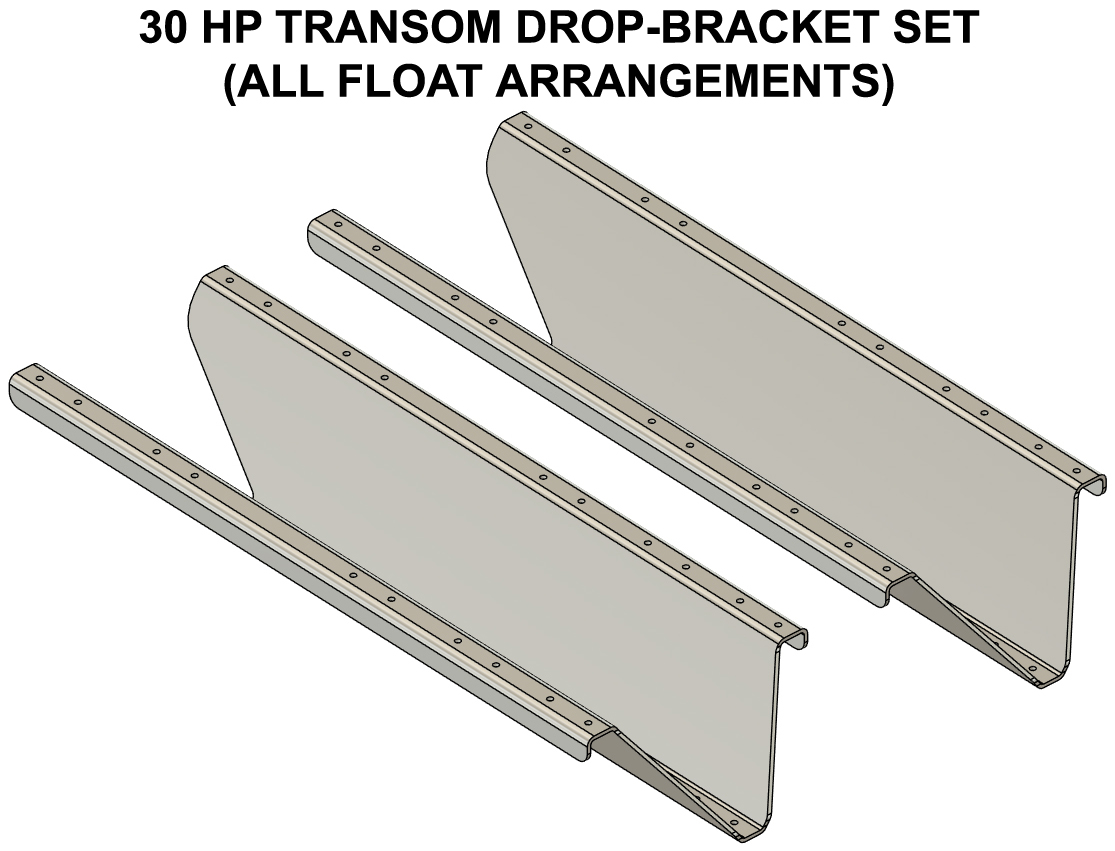

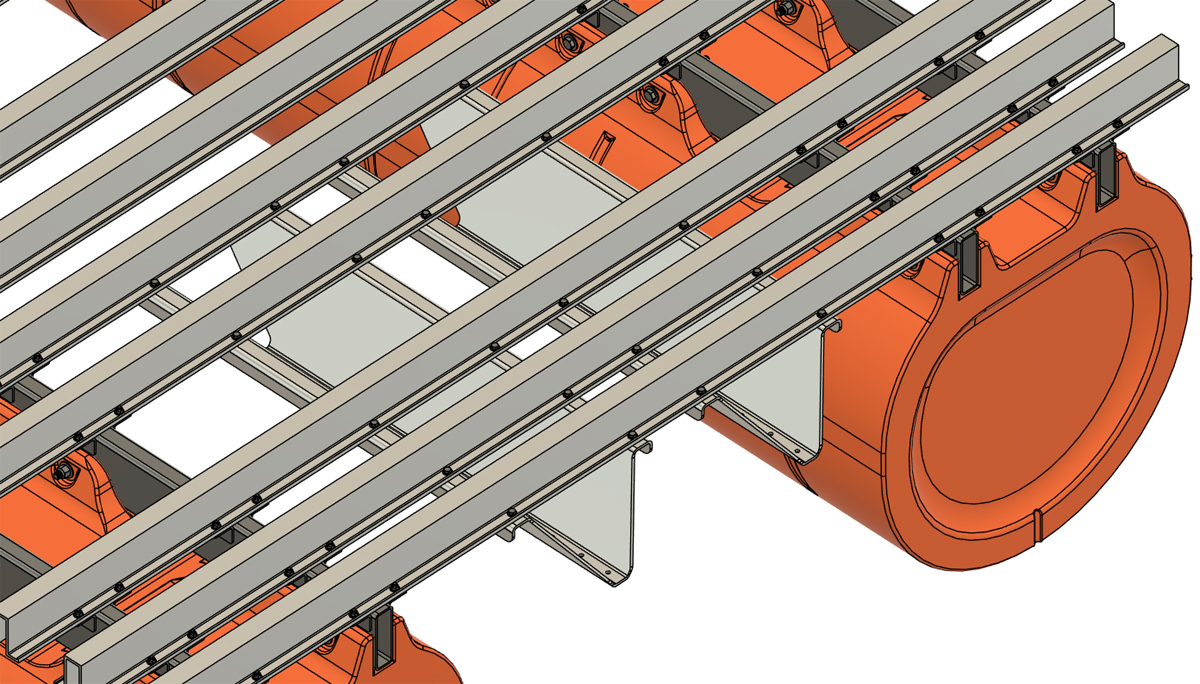

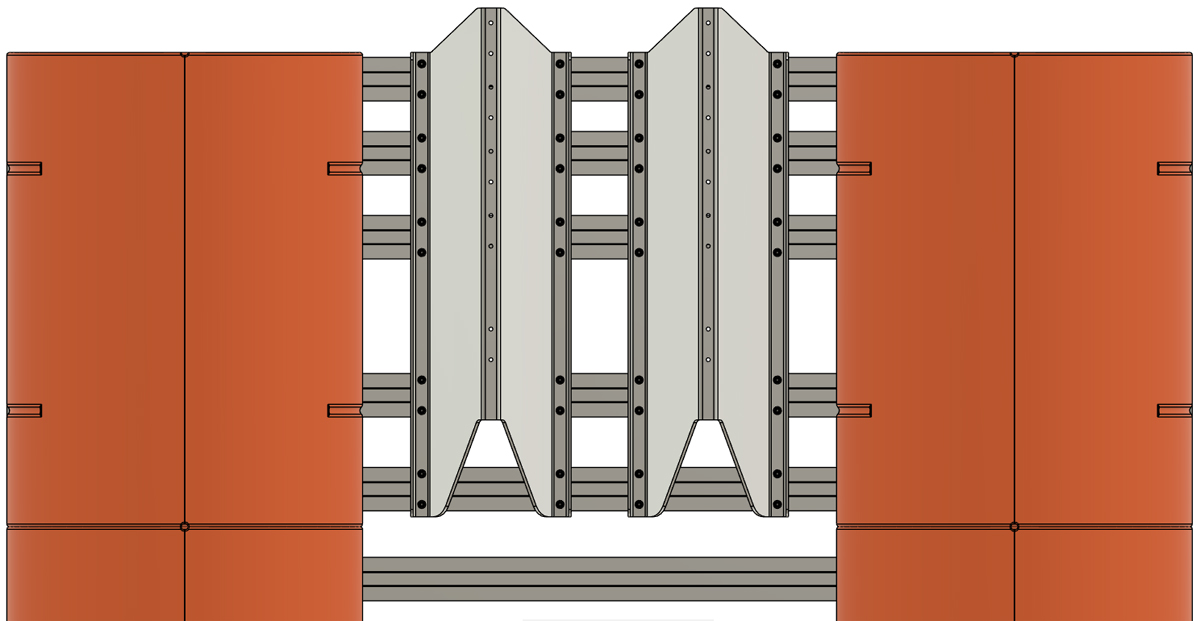

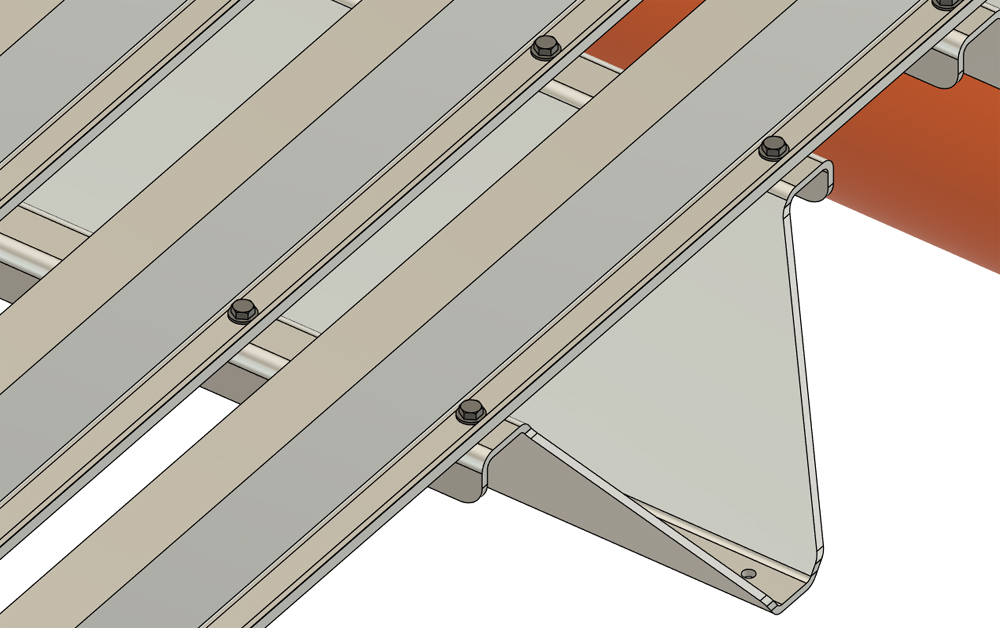

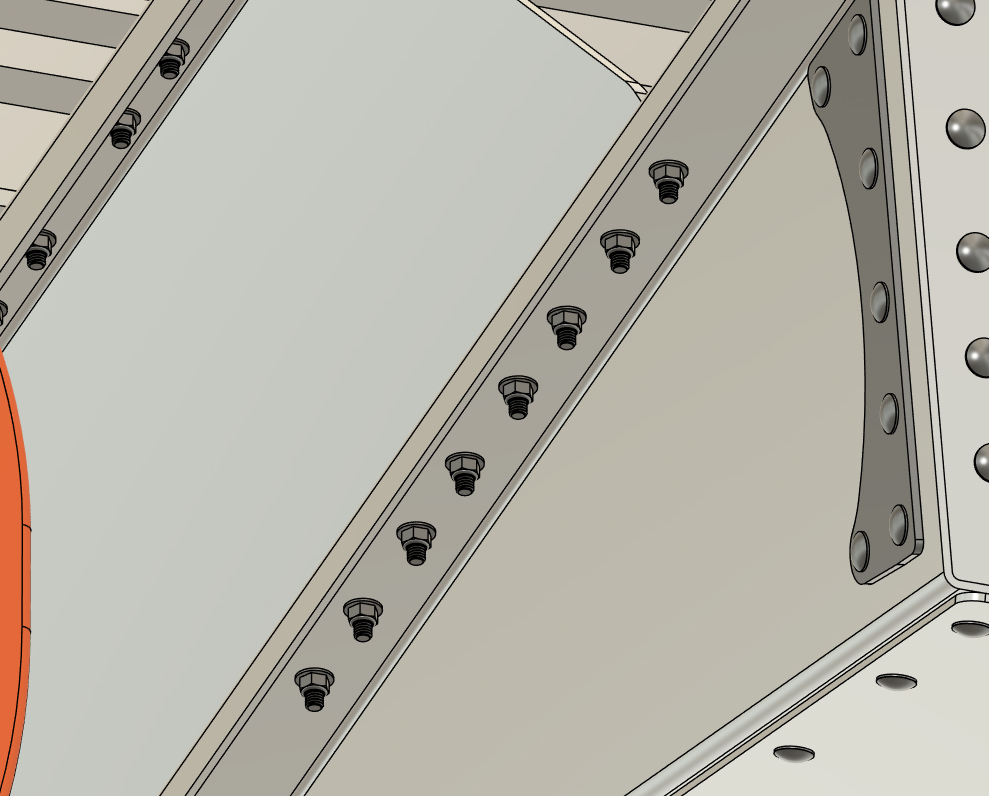

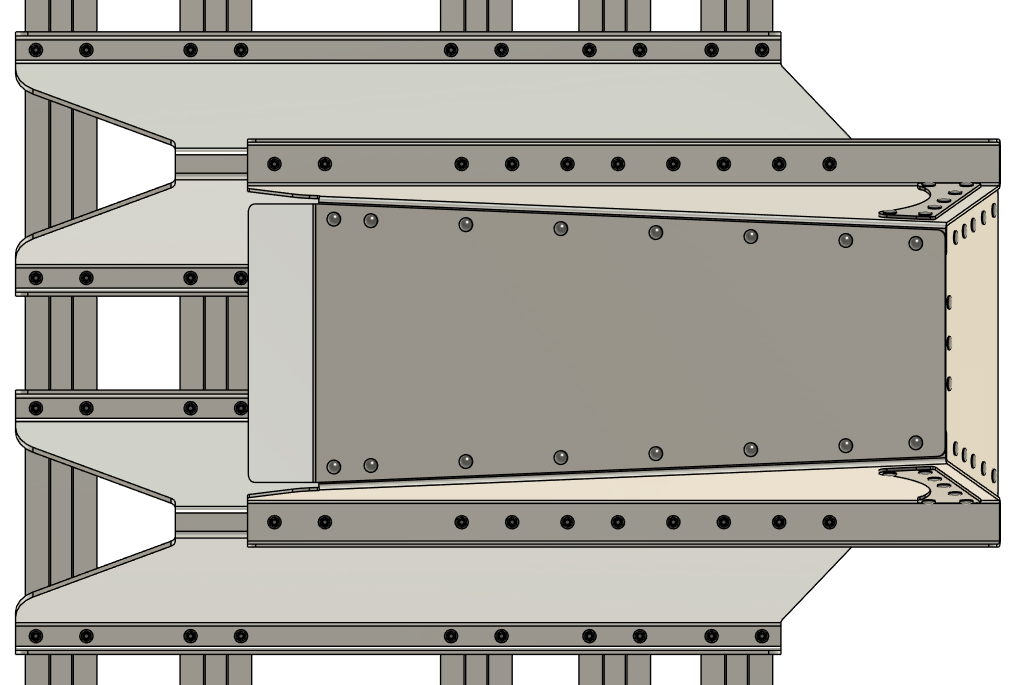

Once again, moving forward, you will have to reference your crossmember placement diagram specific for your barge system. In this set of instructions, the example we are working through is a 10'x24' barge system with a 150 HP transom. The crossmember placement diagram we are working with is shown to the right and will only apply to this particular barge arrangement. We repeat, you must reference the diagram provided to you after your order is placed (or prior if requested). Your crossmember placement diagram shows all the hat channel crossmembers that are now to be bolted to your pontoon assemblies. Please note that the rearmost set of crossmembers for your barge are labeled "RS", and we reference them as the "Rear Set" of crossmembers. If you purchased a transom with your barge system, these crossmembers will have central bolt holes for mounting your transom system. If you did not purchase a transom, all the crossmembers will be identical and your diagram may not have "RS" labels on any of the crossmembers. |