|

SECTION 2

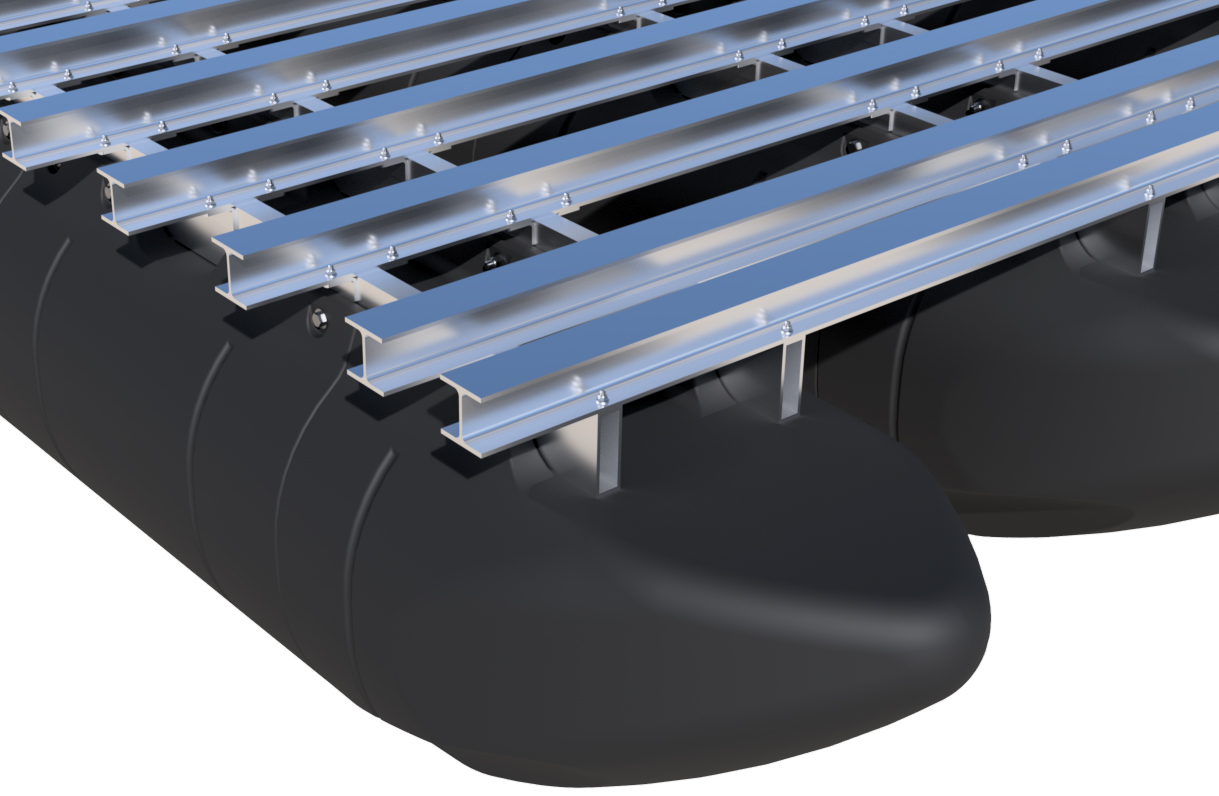

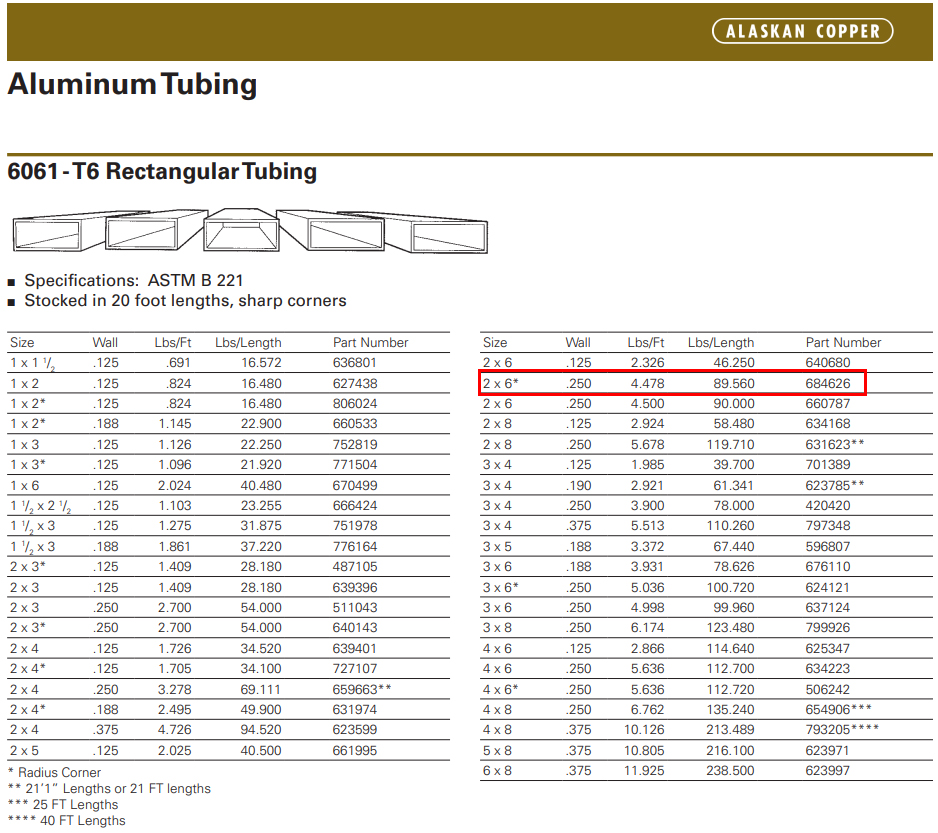

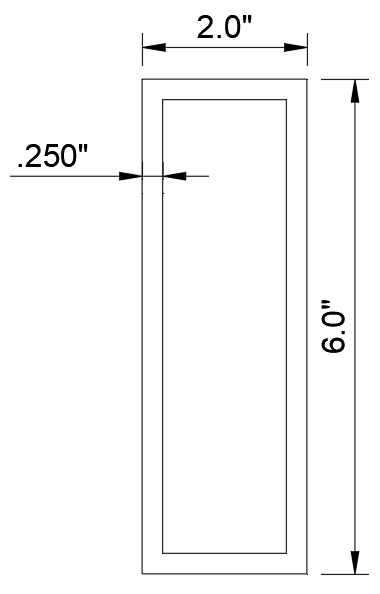

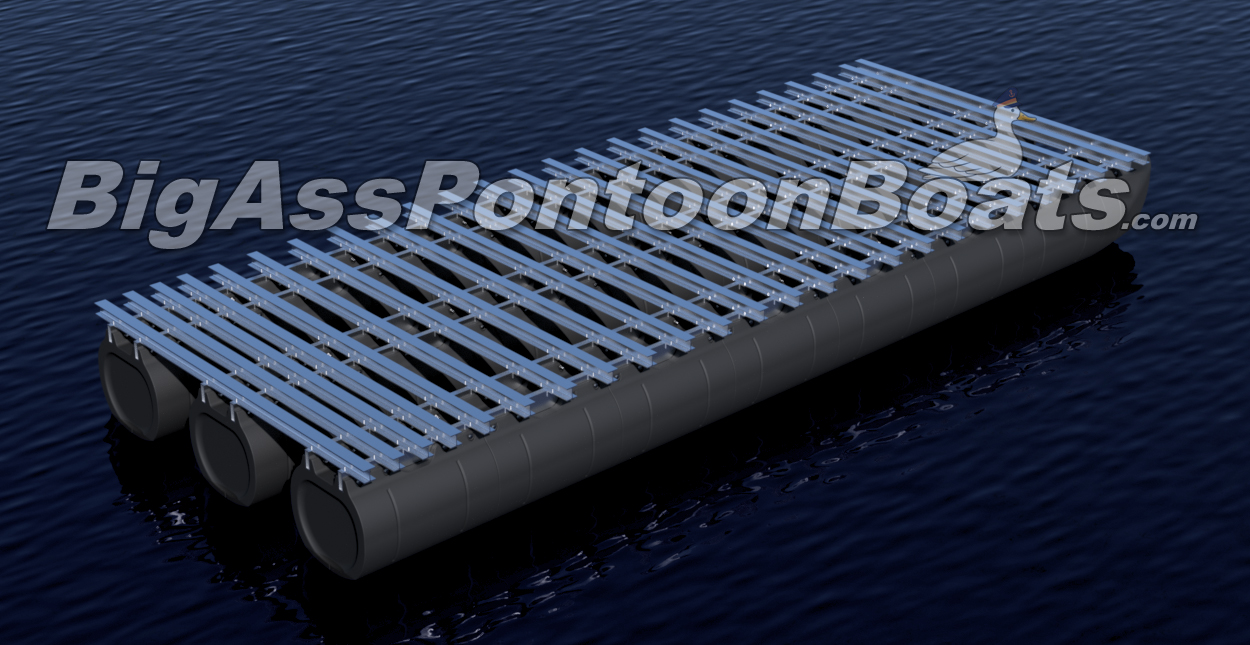

The I-beams are half of the puzzle, so what about the backbone for the floats? You know, the tube that runs the length of each pontoon assembly? That's easy! You need 2"x6", 1/4" wall 6061 aluminum for most barge systems, and many suppliers can get this material in lengths that are much longer than 20' if you ask nicely and have a little patience. Suppliers like

Alaskan Copper,

Metal Supermarkets,

OnlineMetals.com (Thyssenkrupp), and other independent suppliers can typically supply this material in lengths longer than 20'. If you don't have time to wait for longer lengths, you can splice 20' lengths and use gusset plates (recommend design listed later on this page) to ensure that you're making strong connections. Remember, you happen to be an absolute BOSS when it comes to welding aluminum, so you can do this. You said so yourself!

NOTE:

6"x2", 1/4" WALL "RADIUS CORNER" RECTANGULAR TUBE FROM ALASKAN COPPER |

|

|

SECTION 6

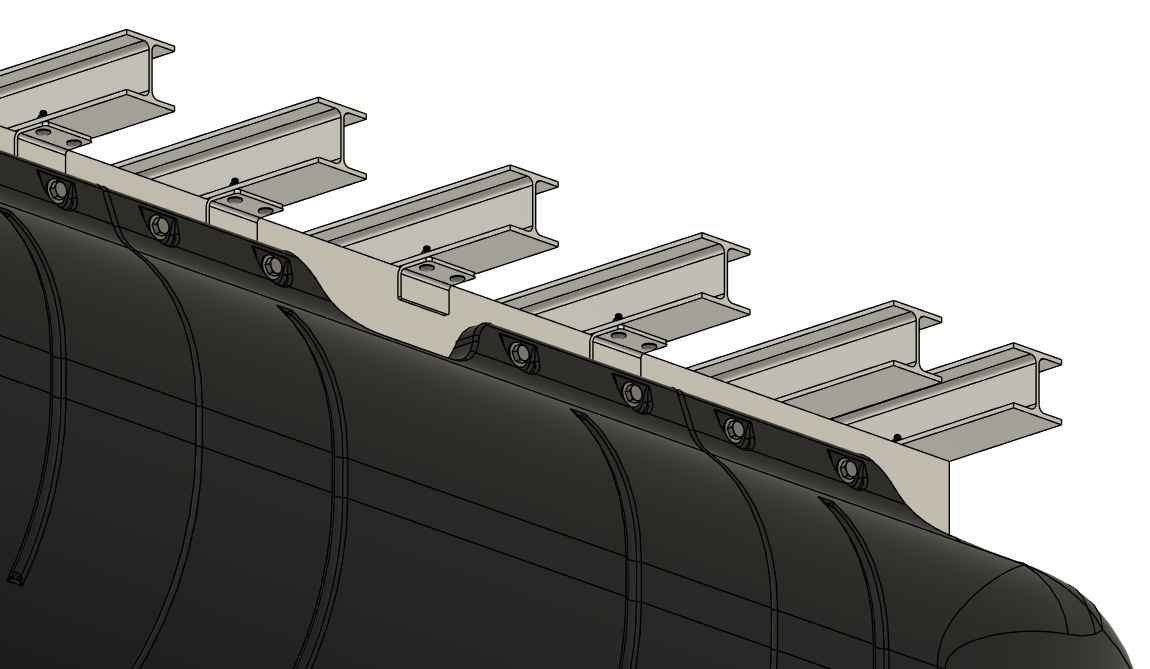

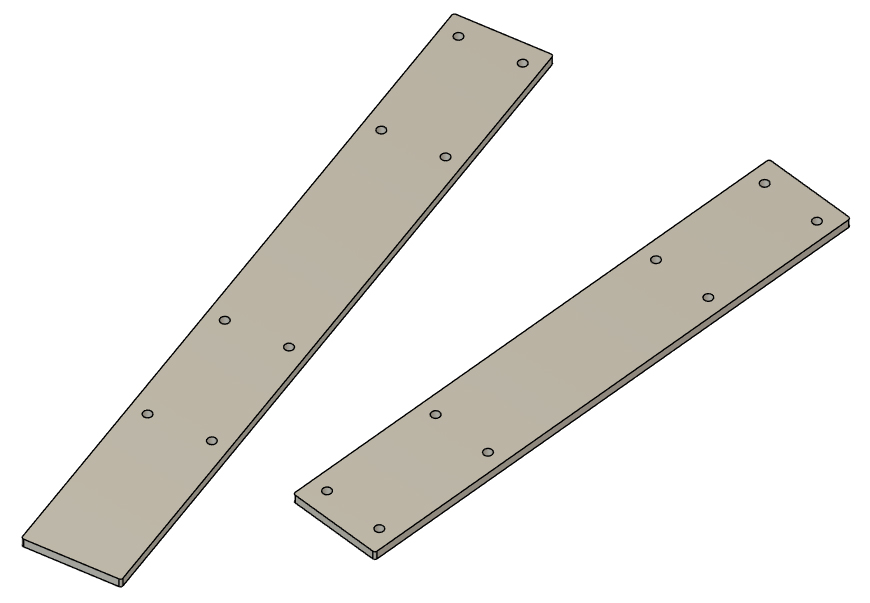

Now you want hole patterns for the crossmembers? Sure, why not?! Here are a couple hole patterns for your I-beam crossmembers. The "Outer Float Hole Pattern" keeps the outer edge of the floats even with the ends of your crossmembers. The "Inner Float Hole Pattern" is for those building barges with 3 or more rows of floats. If building a tri-toon, you'll have to center this pattern on your crossmembers. The hole patterns below are for I-beams that are being bolted to the weld-on brackets:

INNER I-BEAM HOLE PATTERN We mentioned that the I-beams at the end of the barge could be bolted straight through to the Main Tubes, so how about those hole patterns? Well, as the specified 16" on-center spacing for the floats' mounting channels actually lands more toward 15.9" when the floats are cold, you should mark and drill those holes individually. The weld-on brackets allow for the minor variation in the 16" measurement, but if you drill round holes before the rest of the crossmembers are attached, you'll just end up having to over-size the holes to make them fit. Drill and attach those crossmembers after the rest of the I-beams are attached. |

|

|

SECTION 7

If we're providing all this info, we really should provide a hardware list for these frame builds. That's all listed below in a 18-8 stainless steel material and required quantities will vary per design application.

Hardware for crossmembers attaching to weld-on brackets

Hardware for crossmembers bolting directly through Main Tubes

Hardware for attaching floats to Main Tubes

|

|

|

SECTION 8

Since we've gone this far with info, we have a few more tips to share:

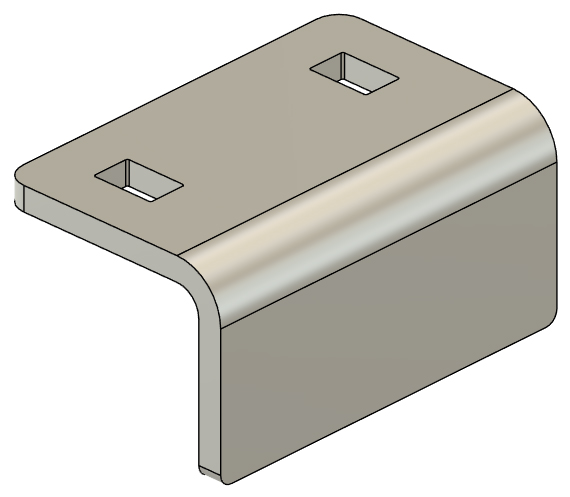

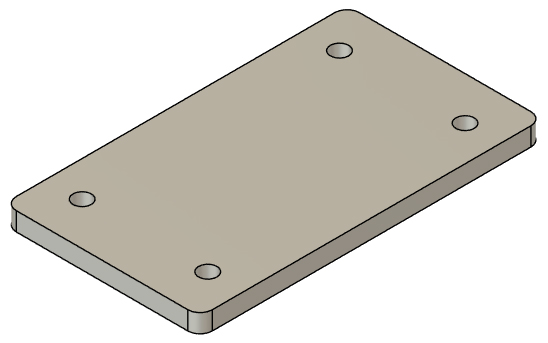

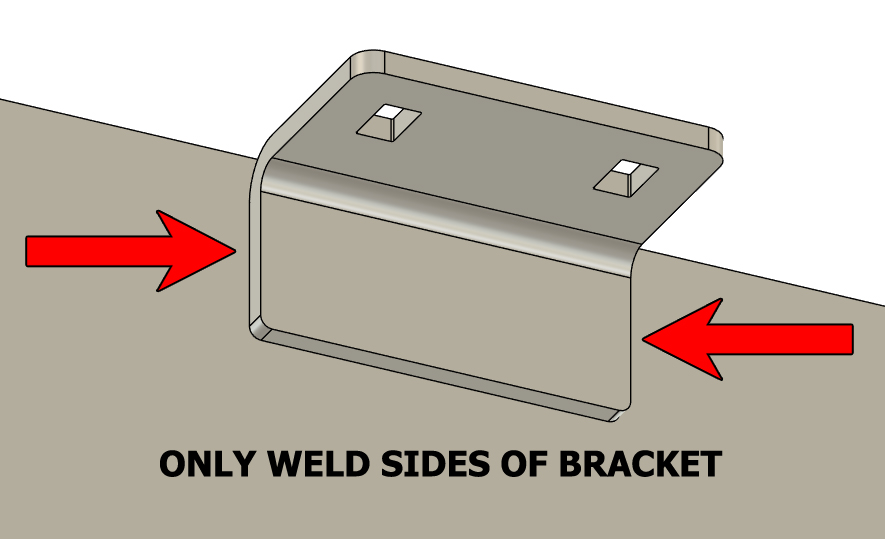

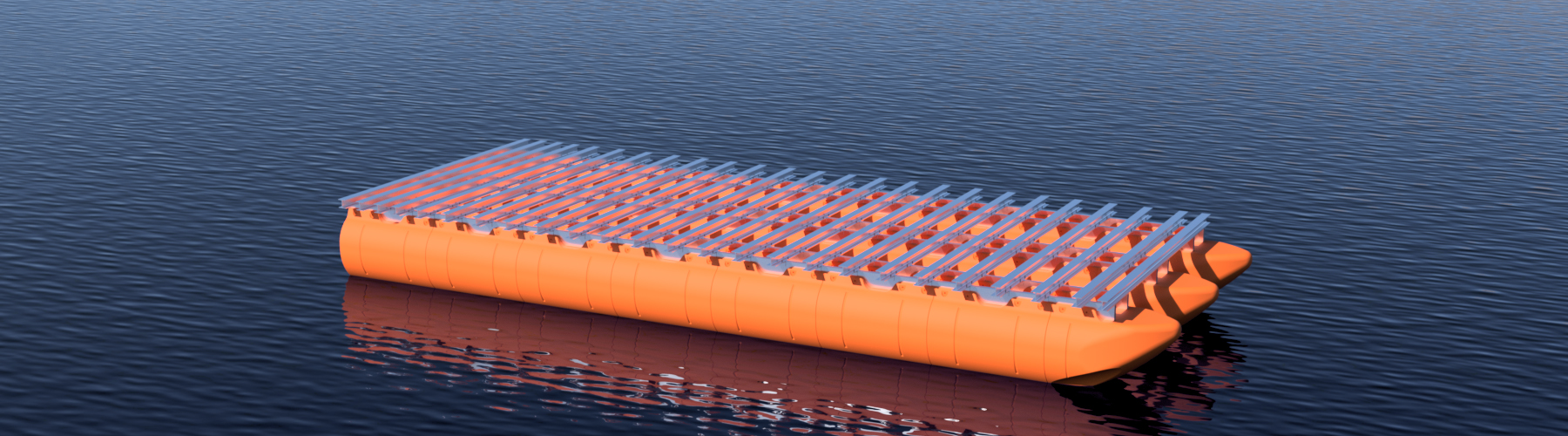

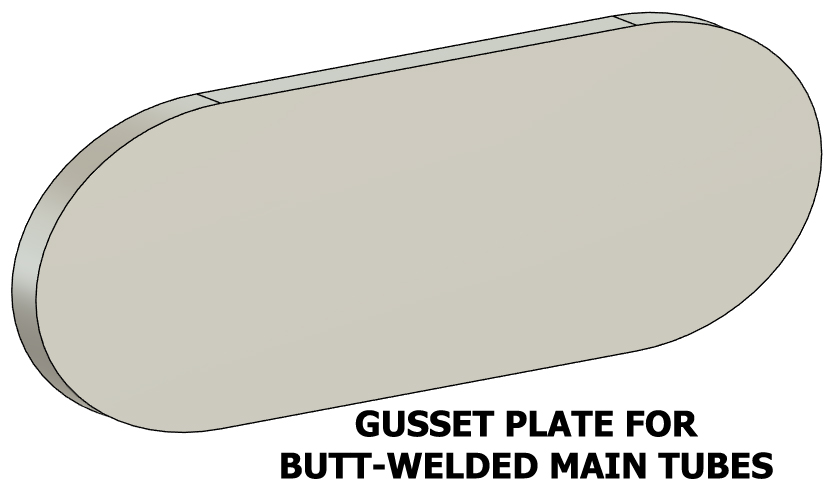

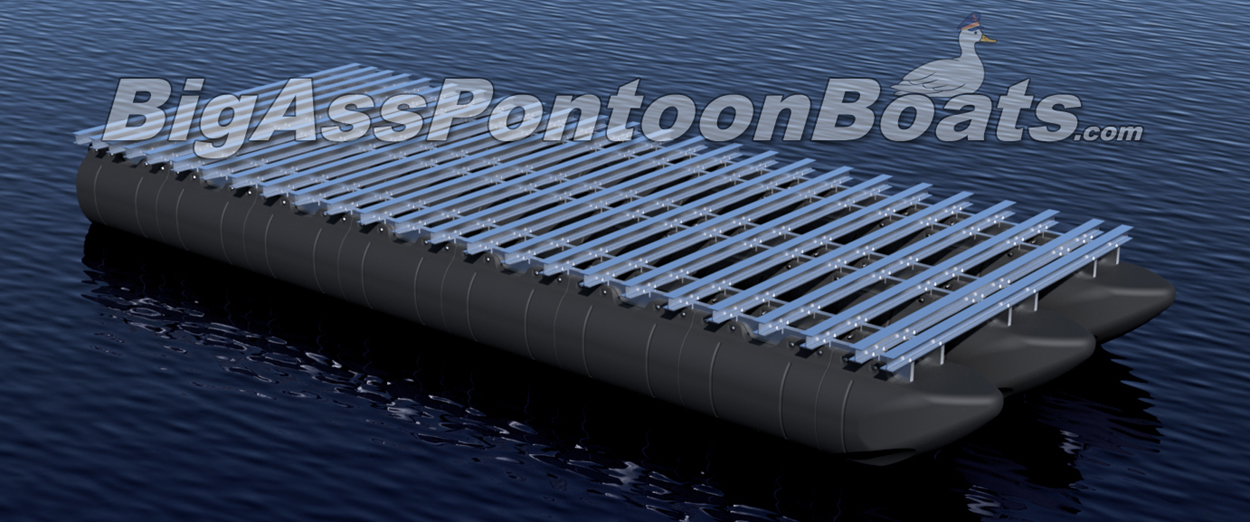

1. This tip applies to folks who are using "sharp corner" 6"x2" rectangular tube for your Main Tubes. If you are able to use the "radius corner" tubing for your barge, this tip does not apply. Before mounting your Main Tubes to your floats, we recommend running a wood-working router with a "corner rounding" bit (1/8" radius or smaller) down the bottom edges of the tube. This stops "sharp corner" tube from digging into the floats over time. 2. We recommend following Step 1-12 of our Full Aluminum Frame System instructions (frame option A) when mounting the pontoons themselves. When reading through the instructions, replace "Main Beam" with your "Main Tube weldments". The rest is the same. Those instructions are listed here: READ THROUGH STEP 1-12 OF FULL ALUMINUM BOLT-TOGETHER FRAME SYSTEM 3. If you need to splice your Main Tubes, you'll need gusset plates for either side of your butt-joints. Here's a CAD file for the gusset plate design that we like for this application. Bear in mind that you'll want to have this plate centered in a recess of a float's mounting channels (centered on a float) and you'll want to space it about 3/4" up from the base of the butted tubes. Also, this gusset plate requires beefy welds all the way around. RECOMMENDED GUSSET PLATE CAD MODEL 4. For the love of Pete, don't ask us for full instructions for this frame concept as we won't provide them as we do for the frame systems that we do sell. What we are providing here is all free information for a system that we are not making a dime on! We will not provide full designs and we will only provide verbal advice from this point forward regarding this expert-level, DIY frame concept. If you're not actually an expert-level fabricator, we recommend sticking with the "Option A" frame system that we offer. 5. Take a good solid look at an example barge system that we have designed with this frame concept to see how it all comes together. We have a 3D viewer and the full CAD model available to download for a 12'x32' triple-row barge system at the link below. |

|

|

DISCLAIMER

The information listed on this page is only for expert-level aluminum welders and fabricators. Silver Lake Fabrication LLC DBA Tiny Pontoon Boats is not responsible in any way for any work not performed directly by Silver Lake Fabrication. Follow these instructions above at your own risk. Our universal terms and conditions apply when using any information or products provided by Silver Lake Fabrication LLC DBA Tiny Pontoon Boats. Full terms and conditions are viewable here.

|