|

REQUIRED TOOLS

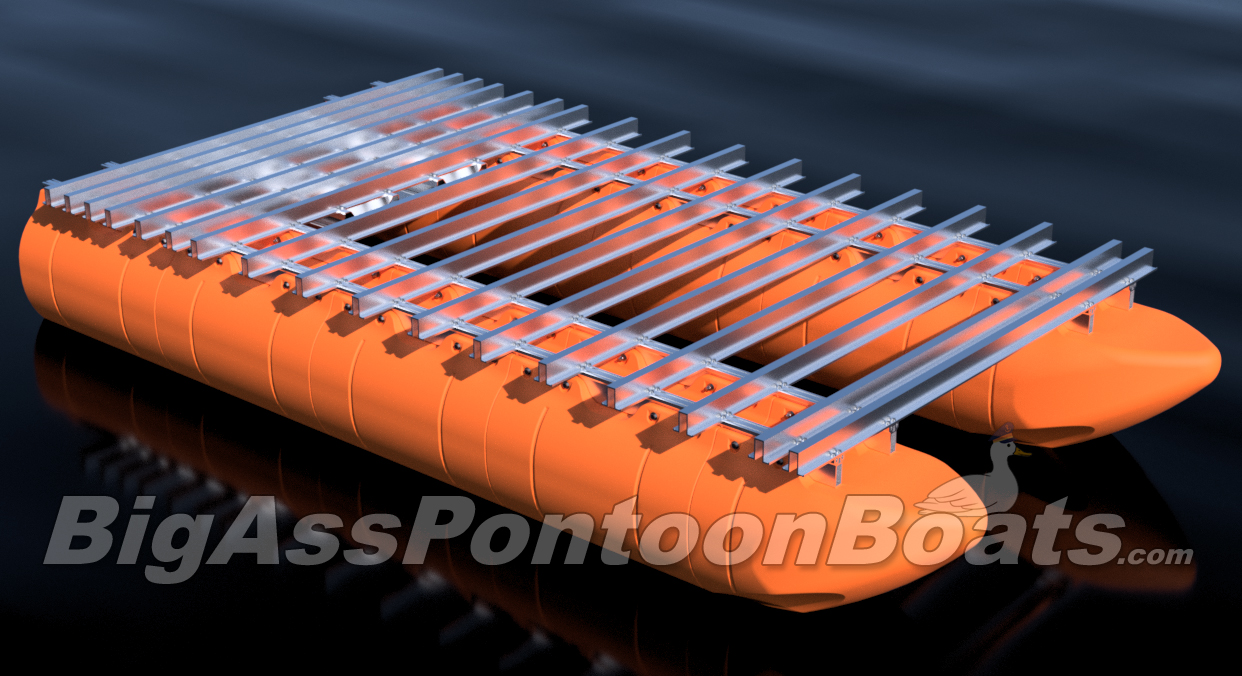

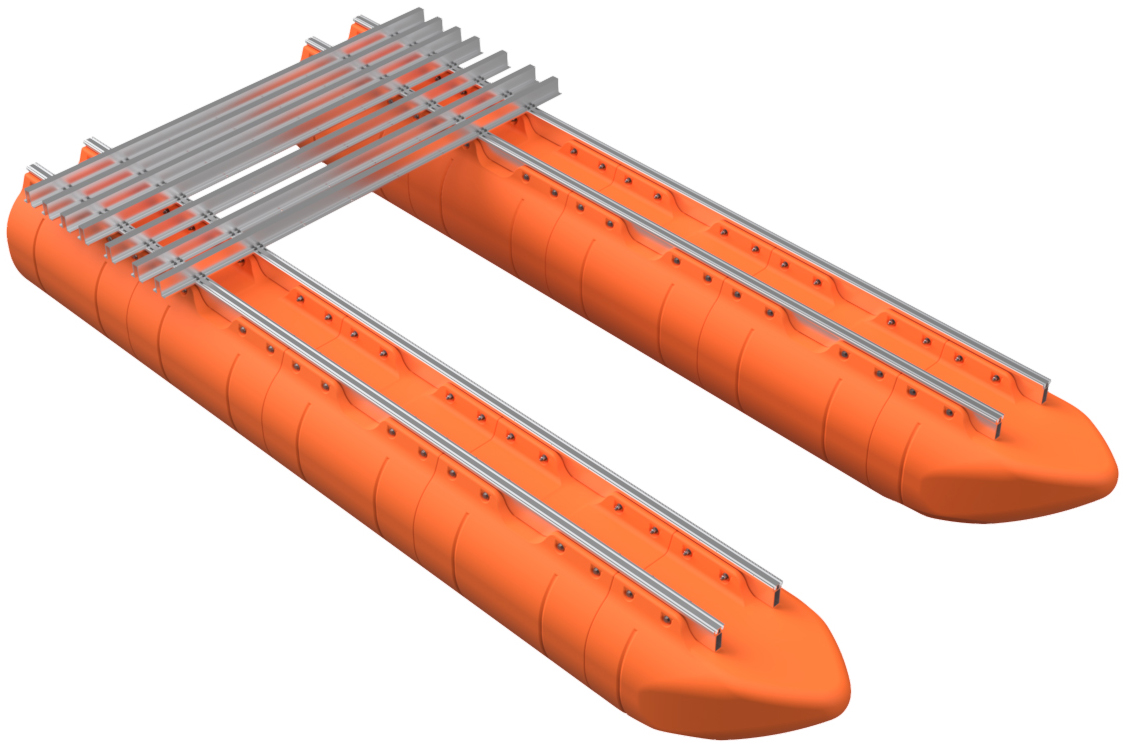

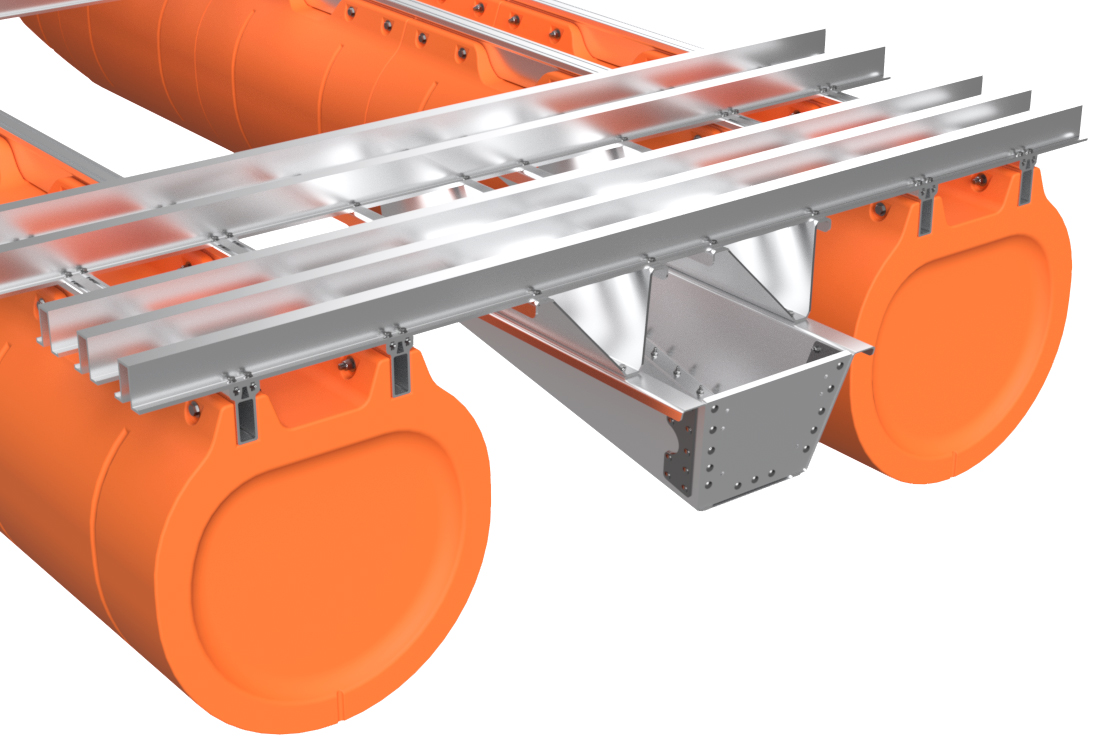

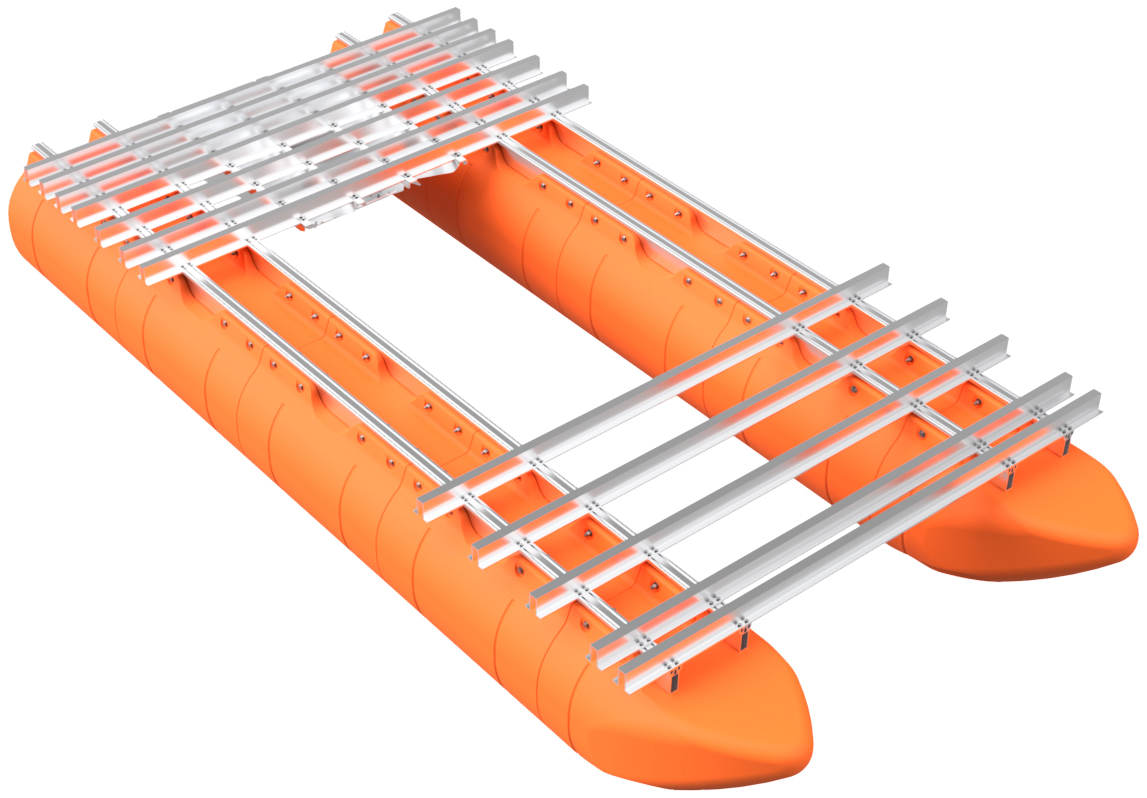

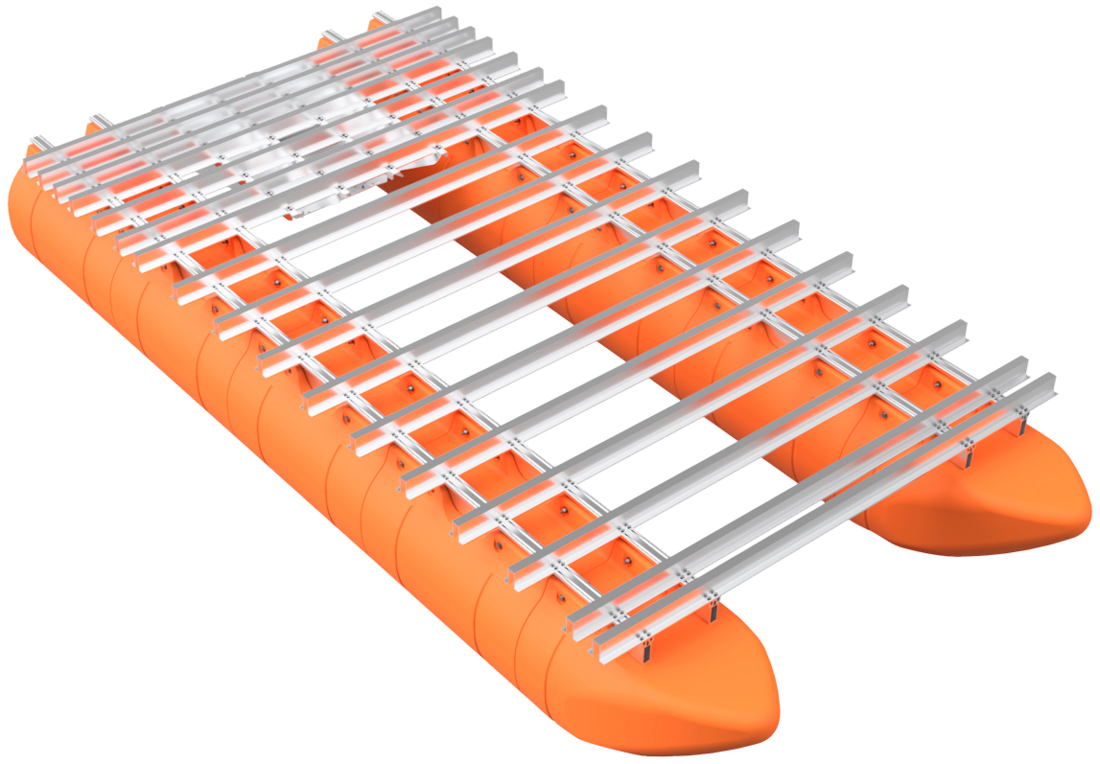

The pontoon and frame system assembly for our full aluminum frame large barge sytems with 36" floats is simple in concept and requires basic tools, a few specific tools, proper lifting equipment, and at least a 2-person team to complete safely. Even our shortest large barge system has pontoon assemblies that land at almost 700 pounds each, so this large-scale system requires a forklift or other lifting equipment to safely assemble pontoons and then move the completed vessel. Failure to be properly equipped for the task of assemby can cause risk of bodily harm, for which Tiny Pontoon Boats is not responsible. Don't underestimate the scale of what you are about to build! As our website states, you're building a Big Ass Pontoon Boat!

Below we have provided a list of everything that you'll need, as well as part numbers and links to where you can get the specialized tools from McMaster, which is a reasonably priced industrial supplier. Click on the part number to view the item on the McMaster website. Many customers will already have the majority of these tools, if not all of them. Many of these tools should be stocked at your local home supply or hardware store as well.

|

|

|

STEP 6

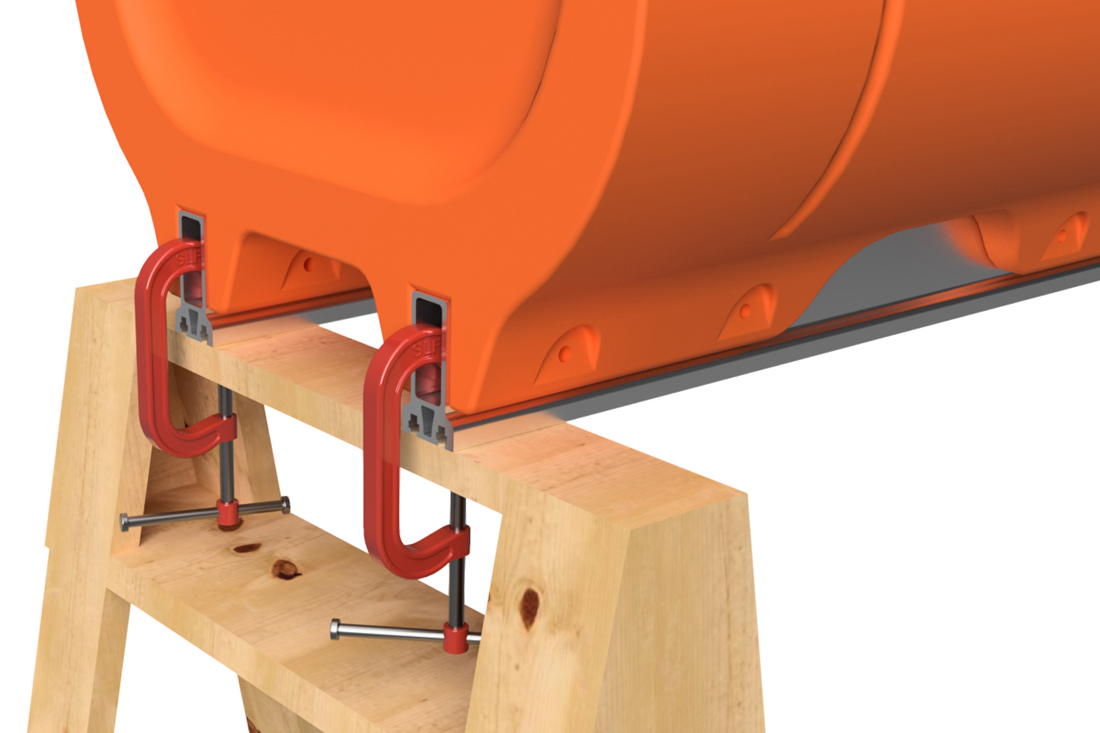

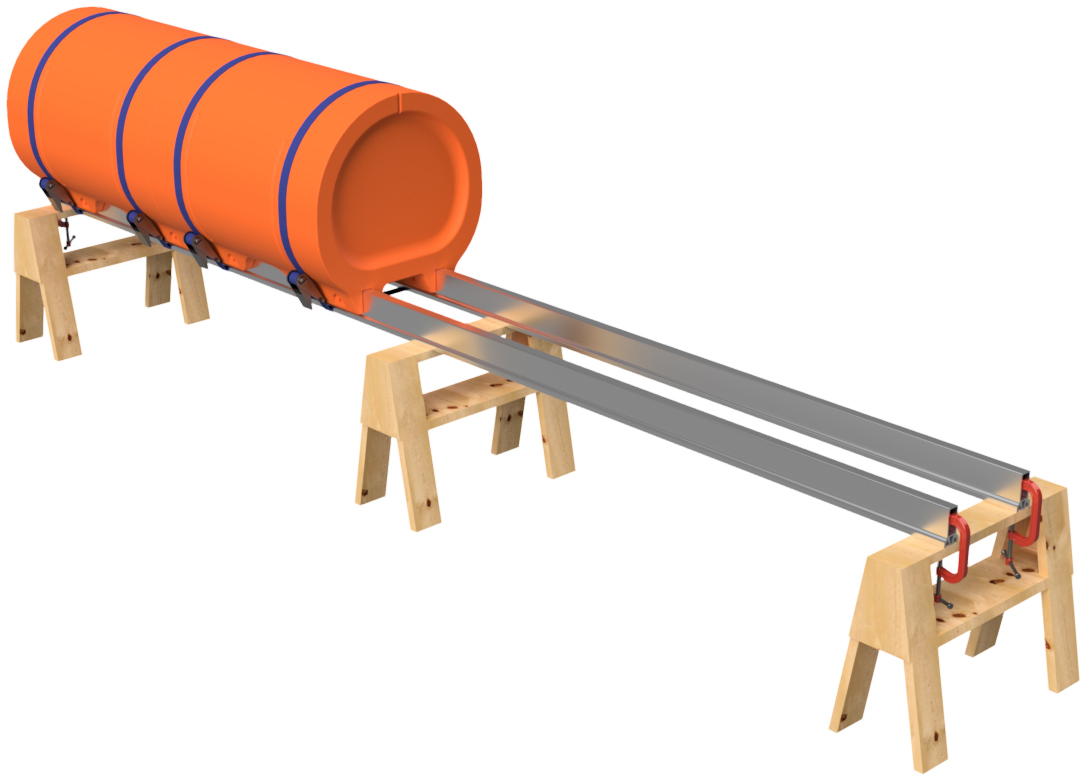

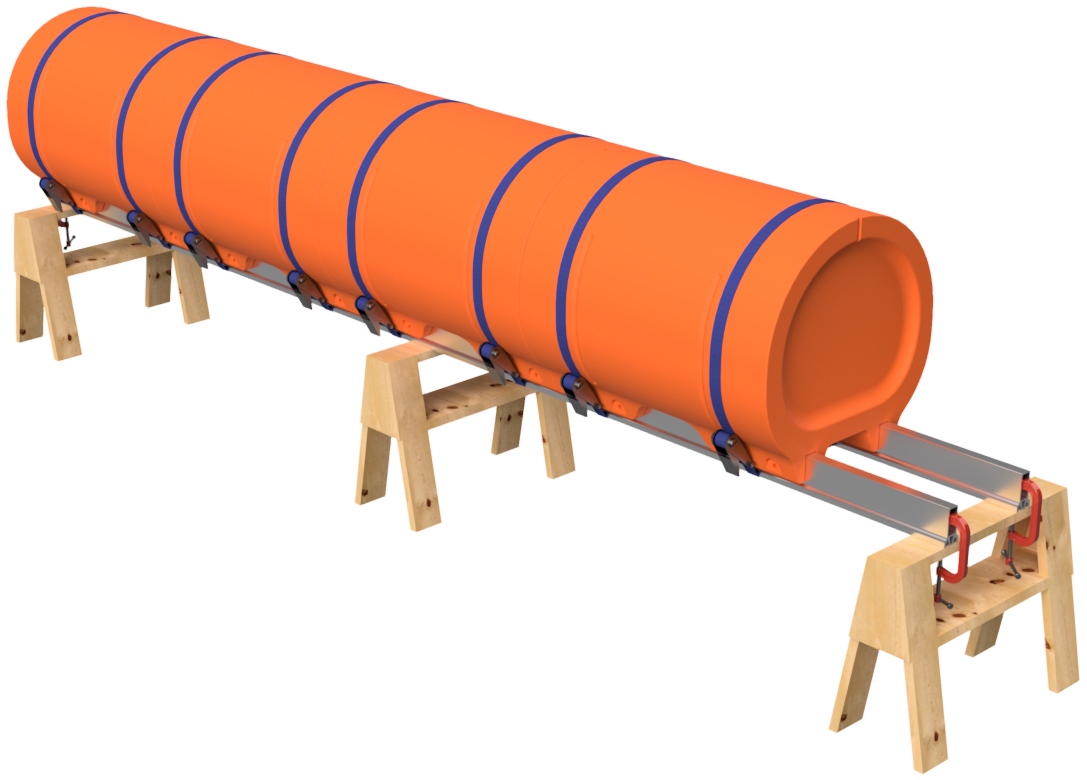

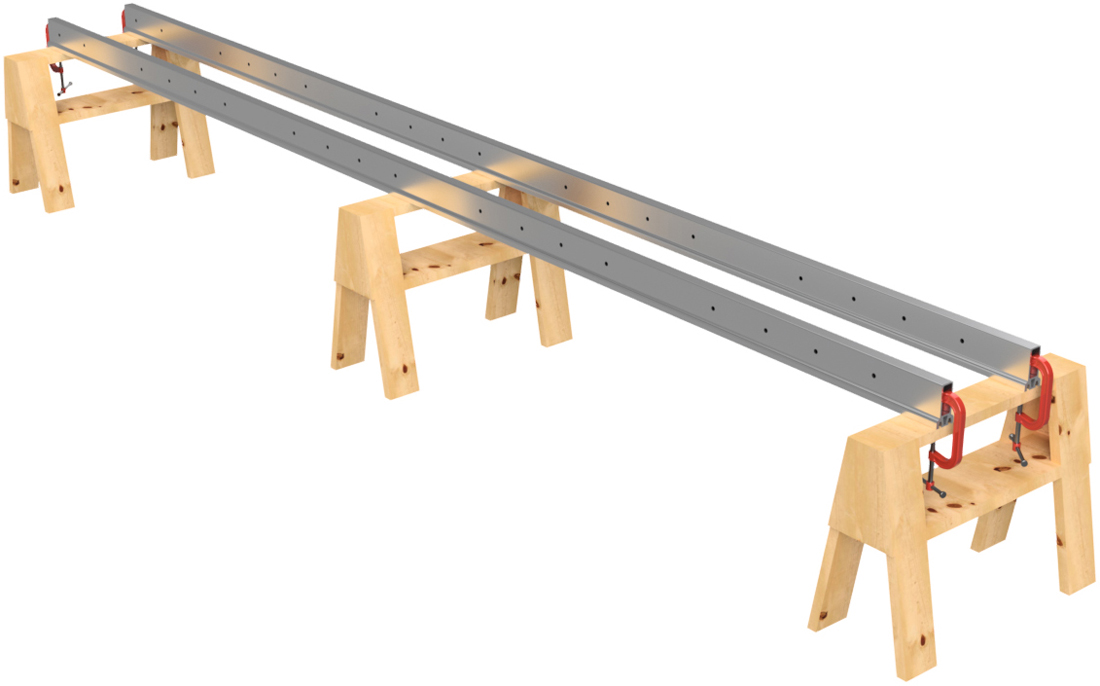

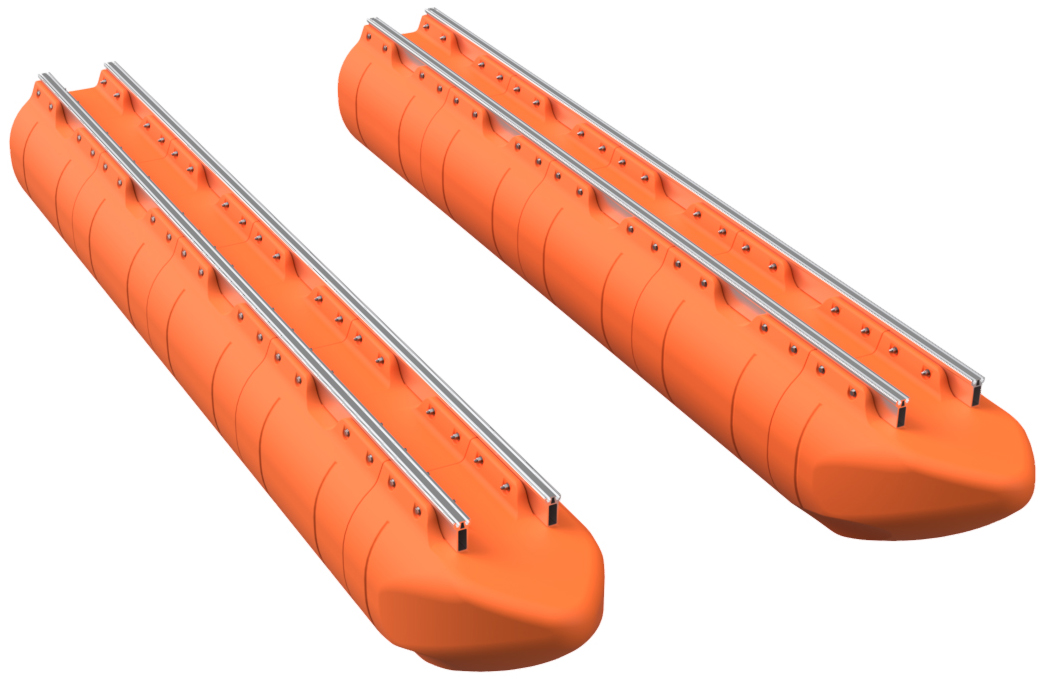

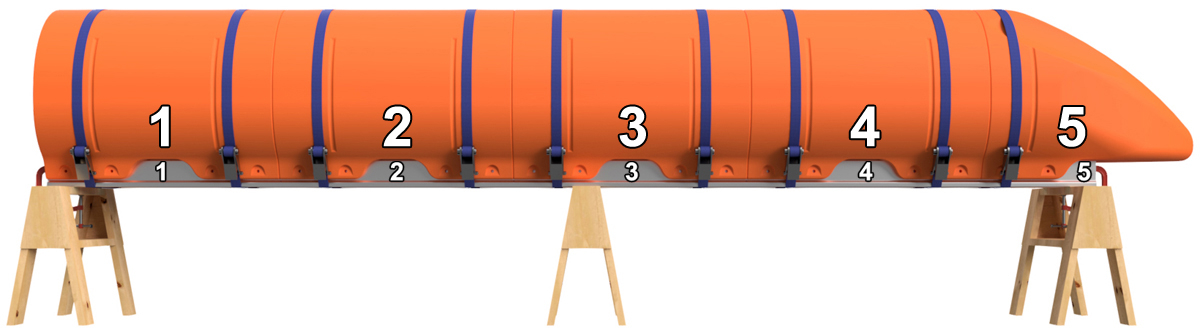

Remove the ratchet straps. Before removing the floats, number the positions of the floats on the Main Beams as shown. Number the floats and Main Beams on both sides of the pontoon assembly. For instance, if you're building a 20' long pontoon, you'll want to label position 1, 2, 3, 4, and 5 on one side and 6, 7, 8, 9, and 10 on the other. This ensures that you don't mix up the positions of the floats after you drill holes. You can use a piece of masking tape to write on or you can use a marker to write on the floats and Main Beams. If using a marker, lacquer paint thinner will remove the ink after assembly, and the paint thinner will not hurt the plastic or the aluminum. Remove the floats and unclamp the Main Beams from the saw horses.

|

|

STEP 7

Using a standard center punch, make the marks you made with the transfer punch in step 5 more pronounce. This will make the holes easier to drill in the next step.

|

|

|

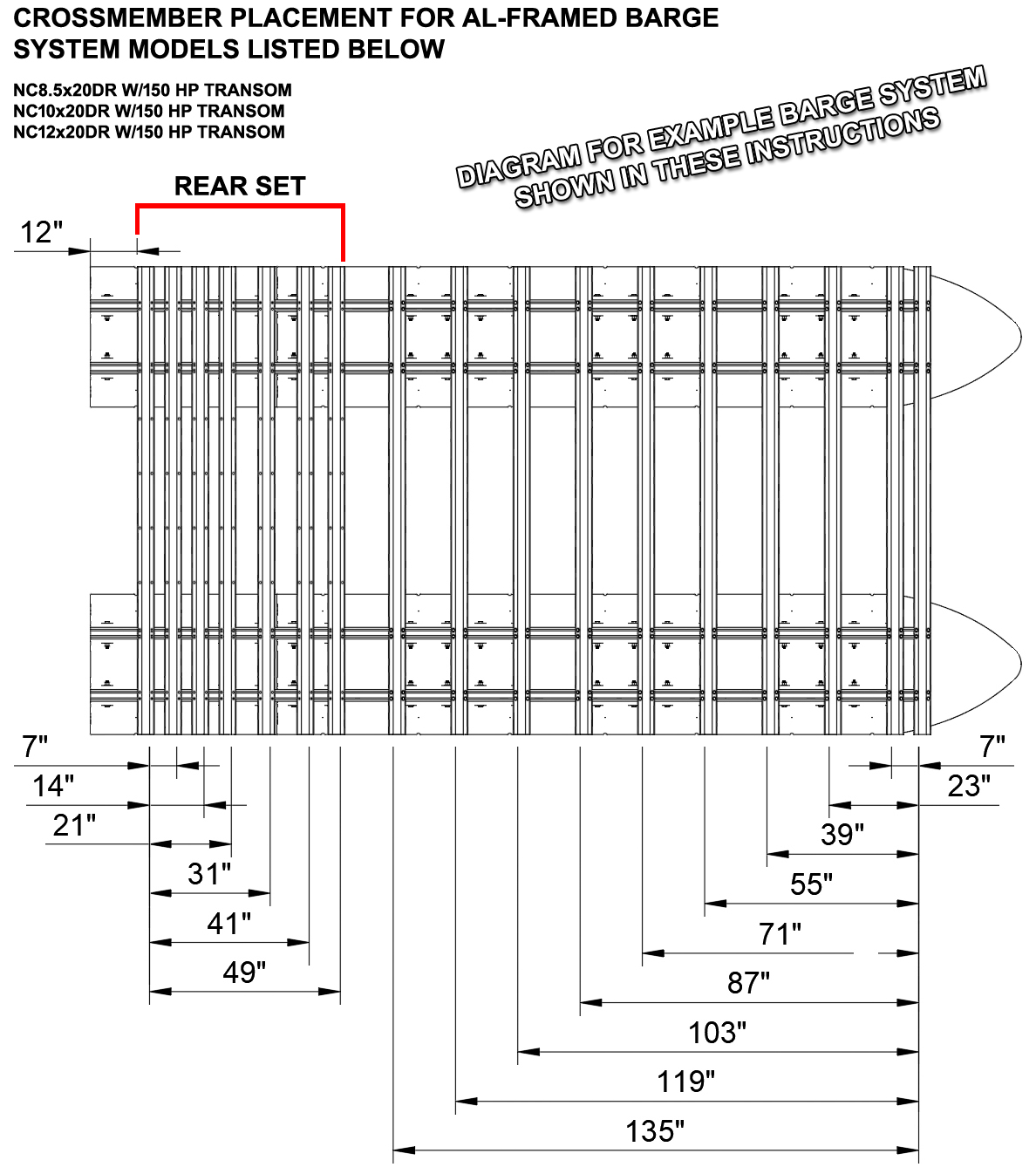

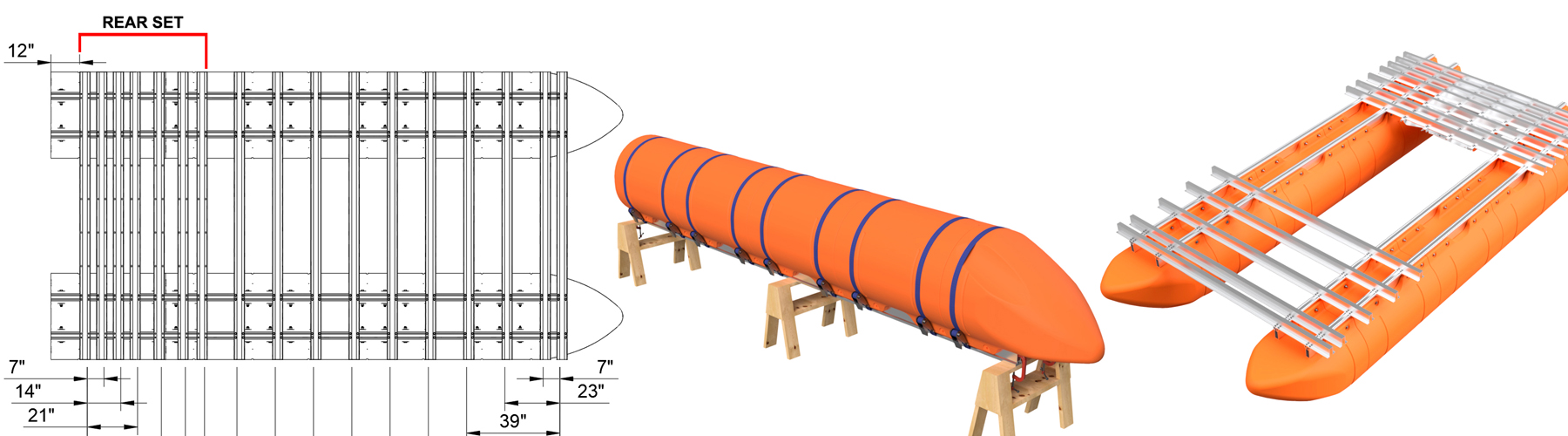

CROSSMEMBER PLACEMENT DIAGRAMS:

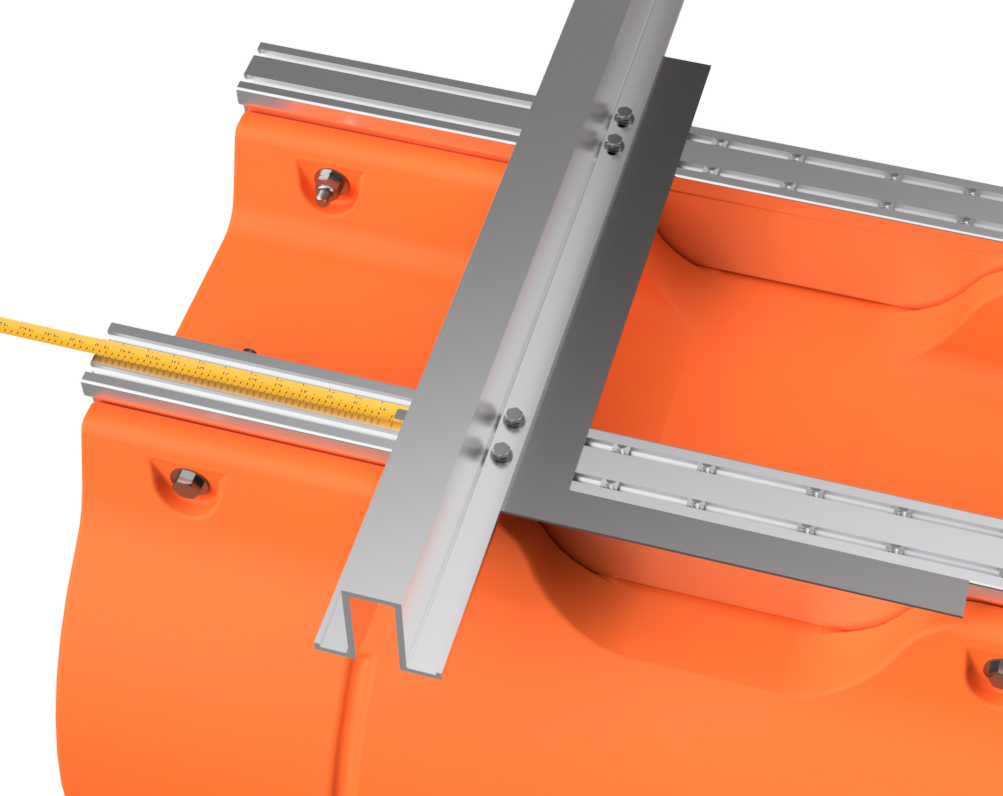

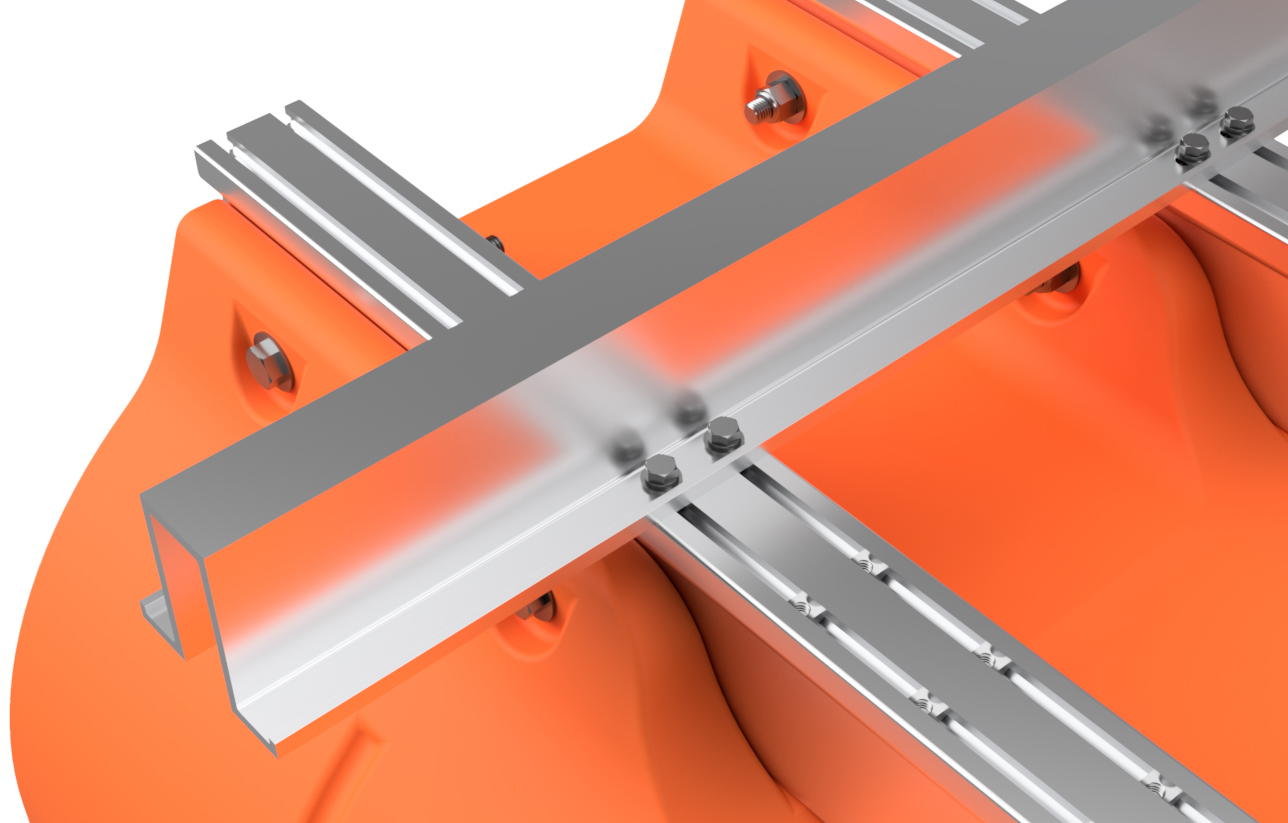

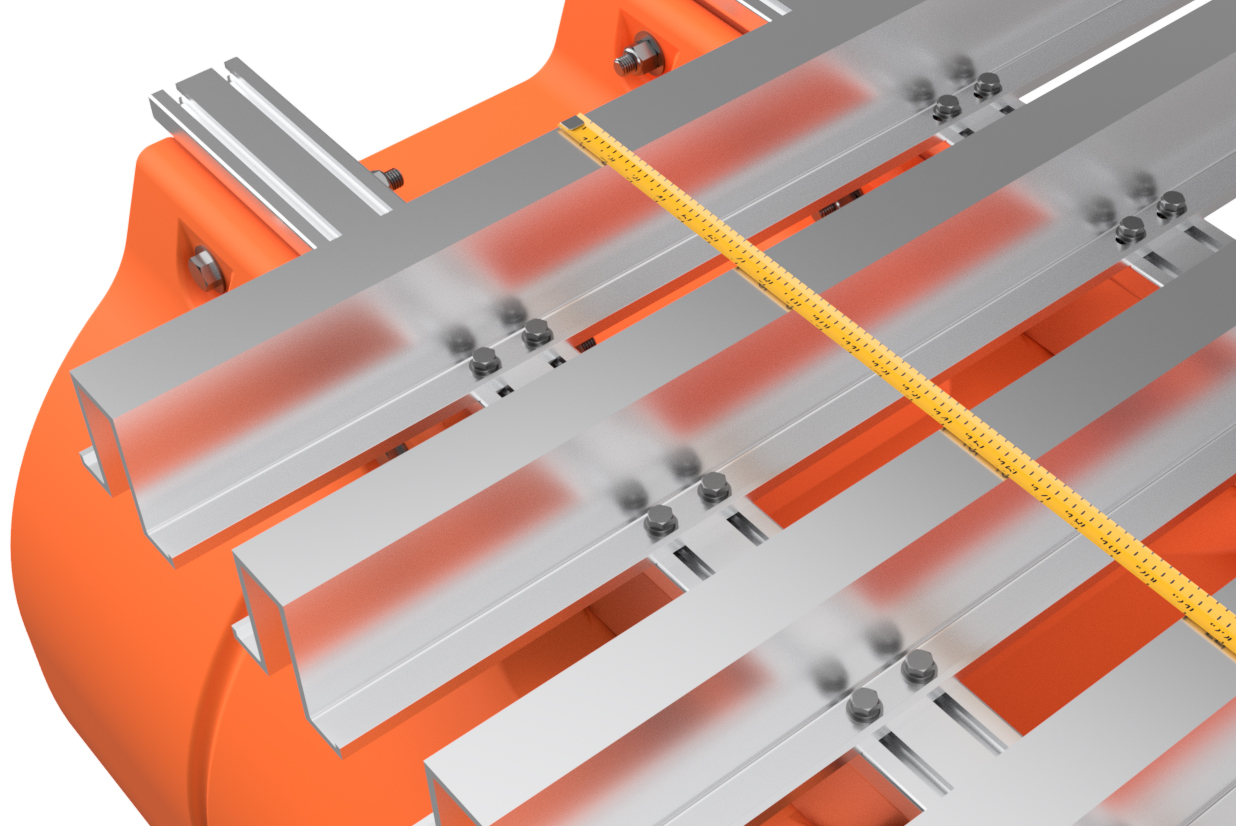

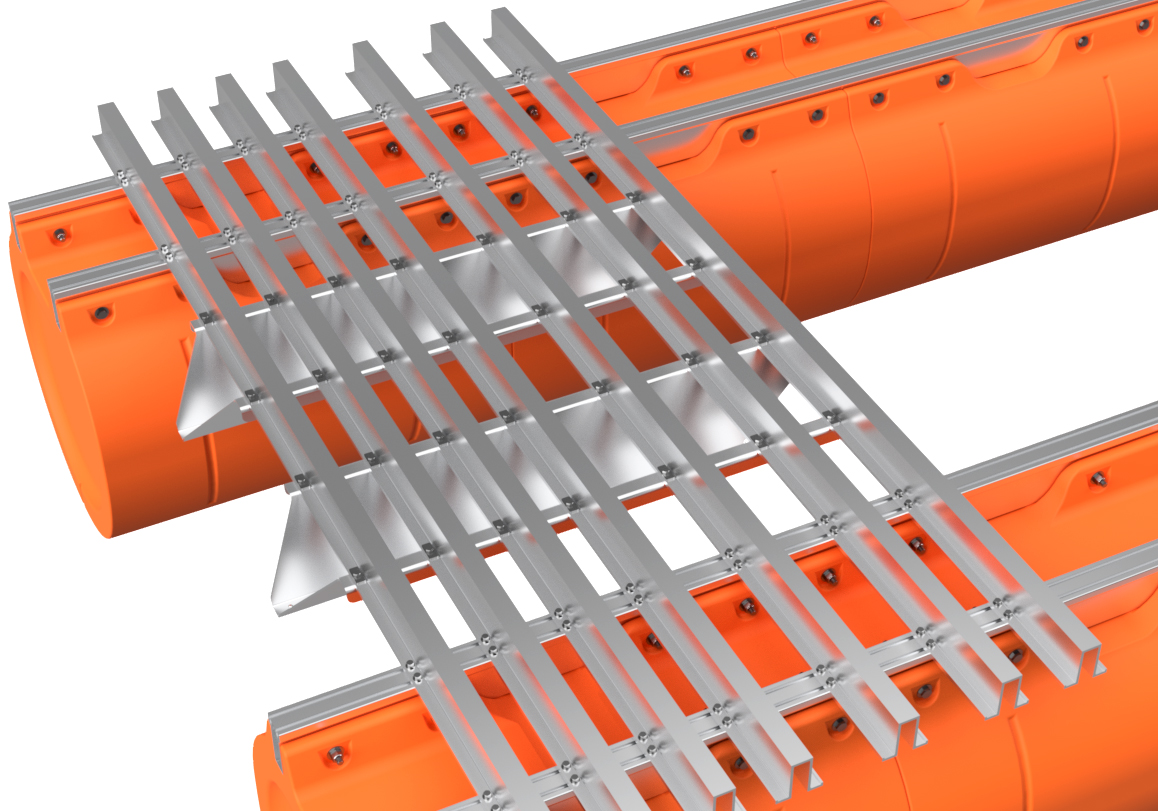

Moving forward, you will have to reference the crossmember placement diagram applicable to your specific barge kit. At this time, we do not have diagrams for every standard option on our site, but the applicable diagram will be provided after your purchase. If possible, print your required diagram or have it handy on a mobile device as you will need to reference it throughout the remaining assembly. The diagram is particularly important to follow if you purchased additional accessories designed to mount to specific crossmembers on your barge. Be careful and double-check all crossmember placement before fully tightening bolts from this point forward.

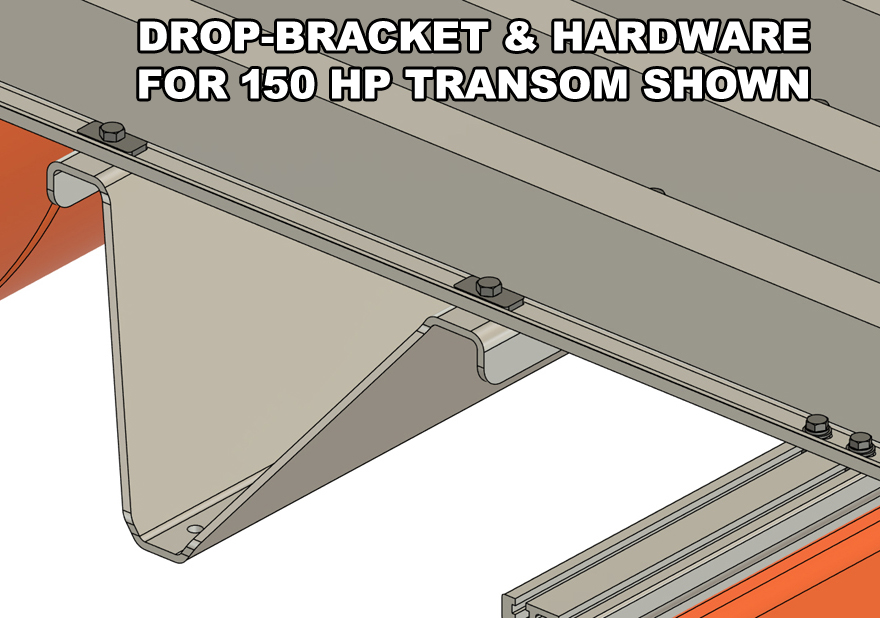

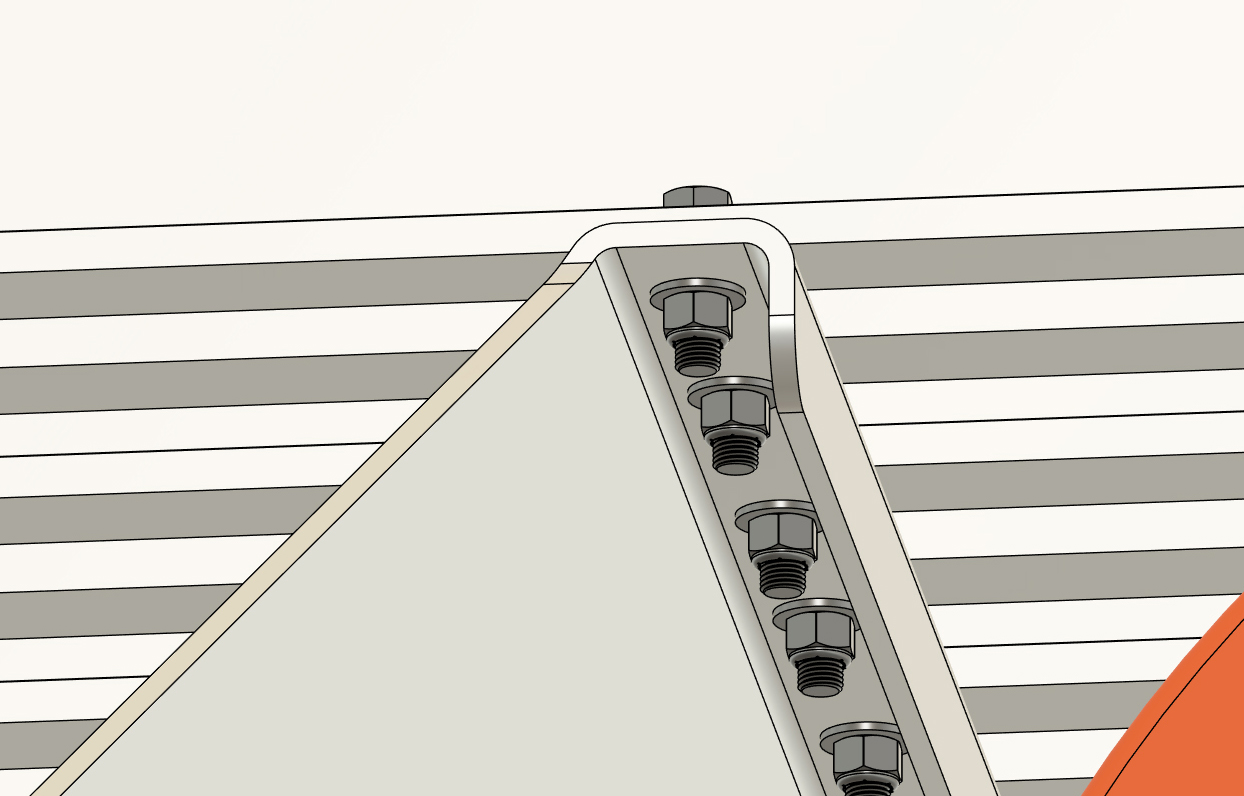

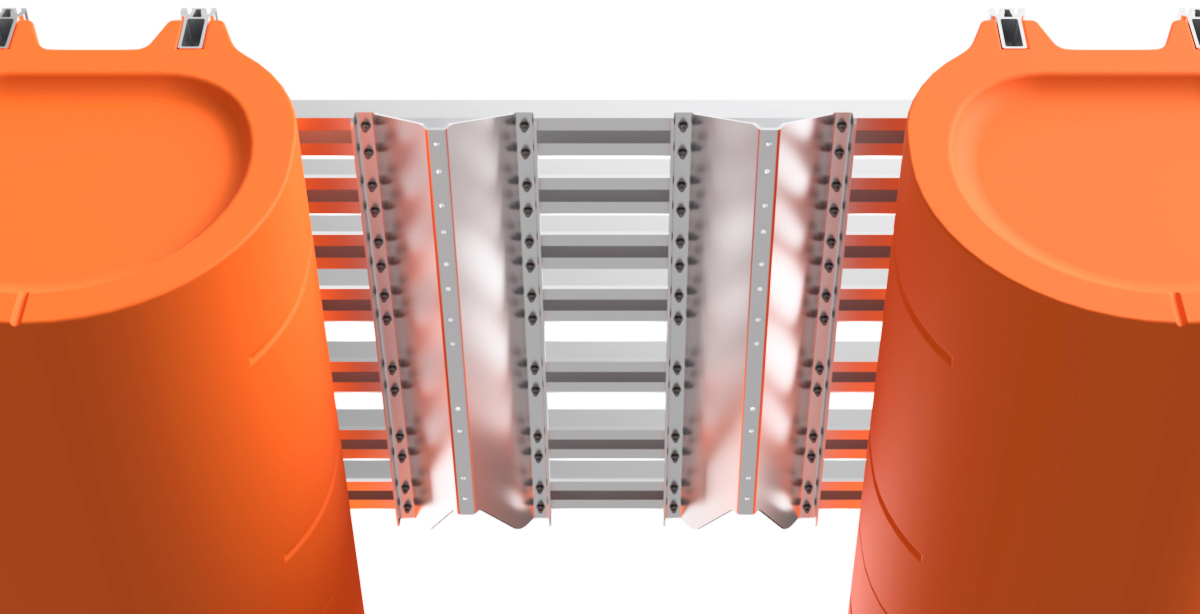

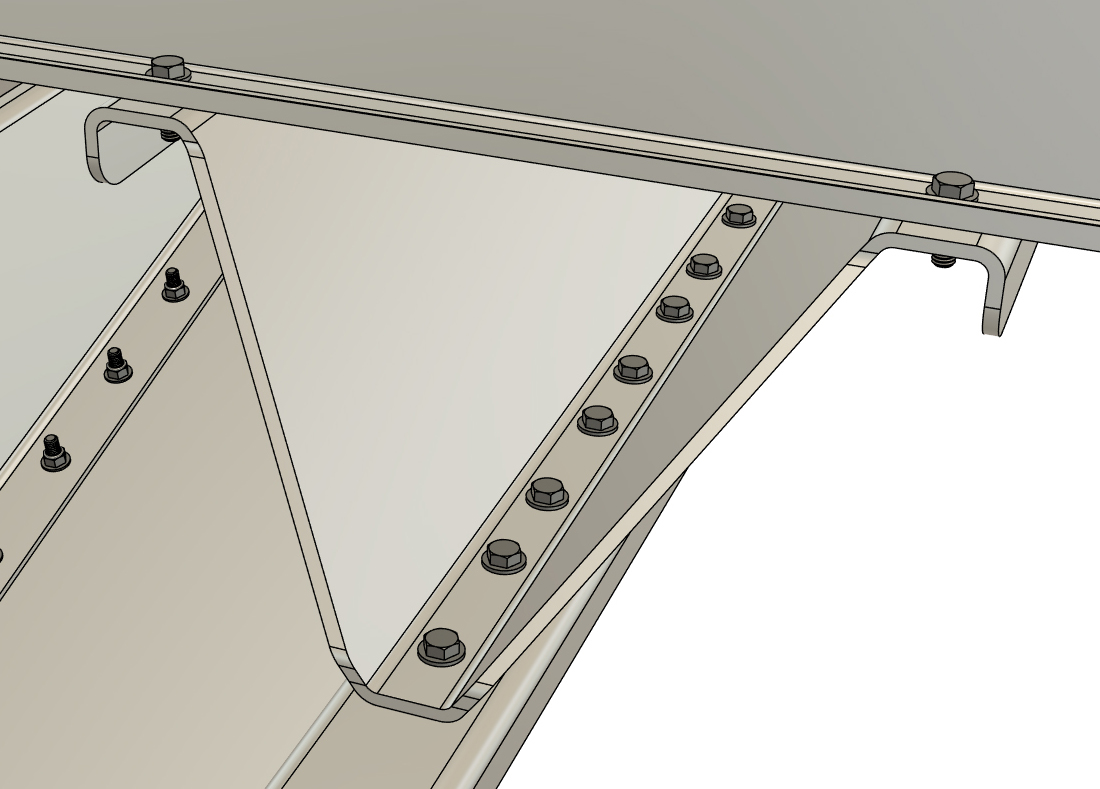

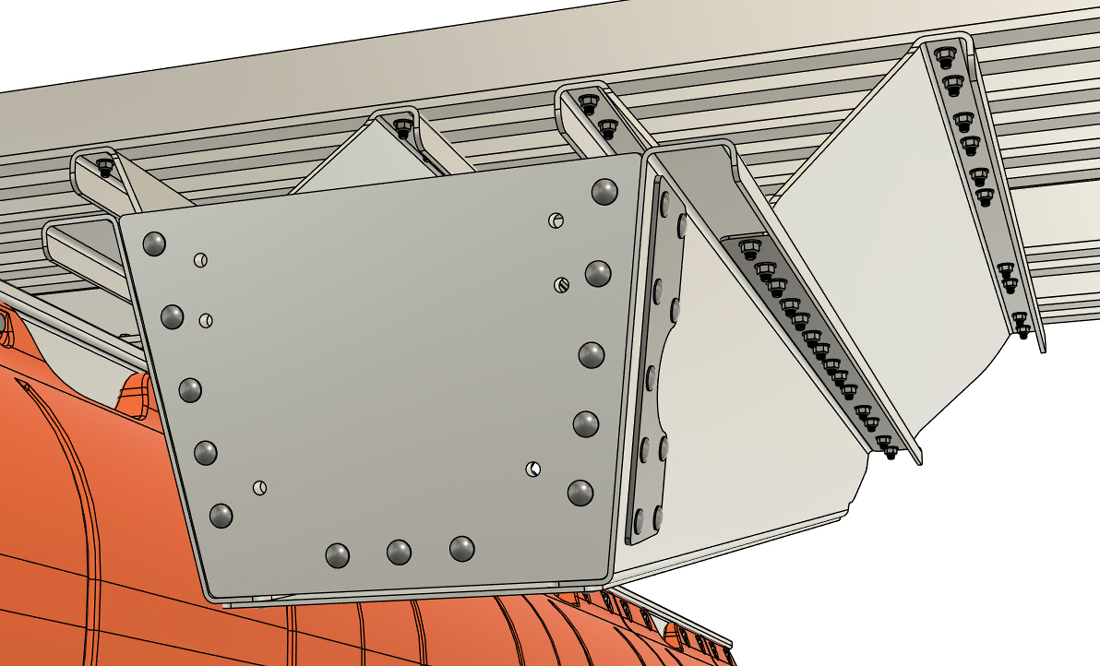

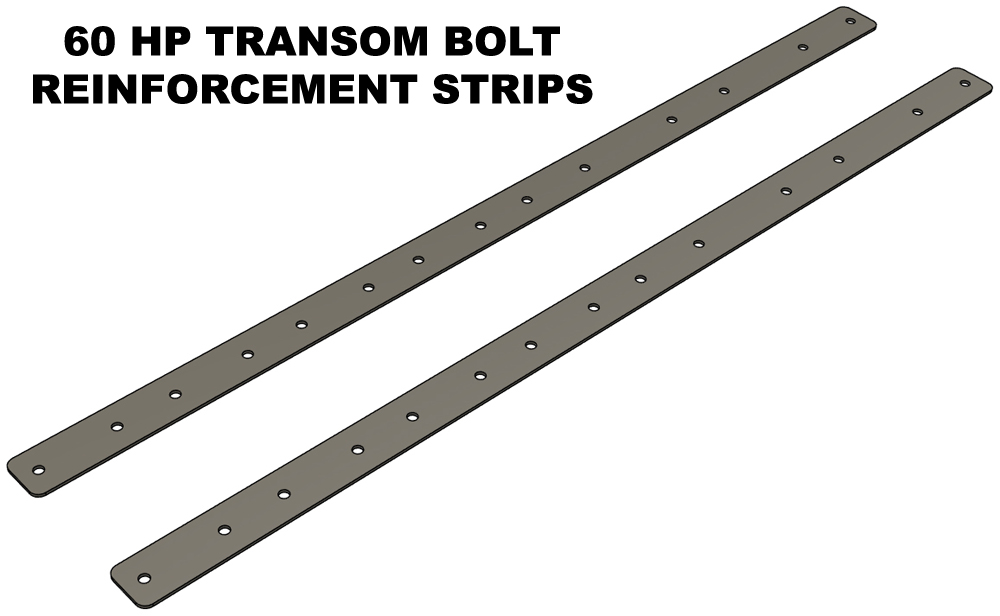

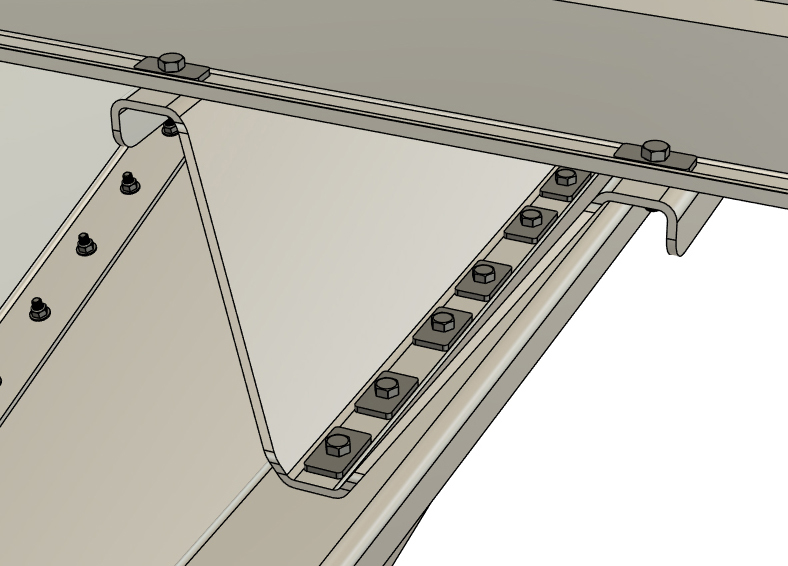

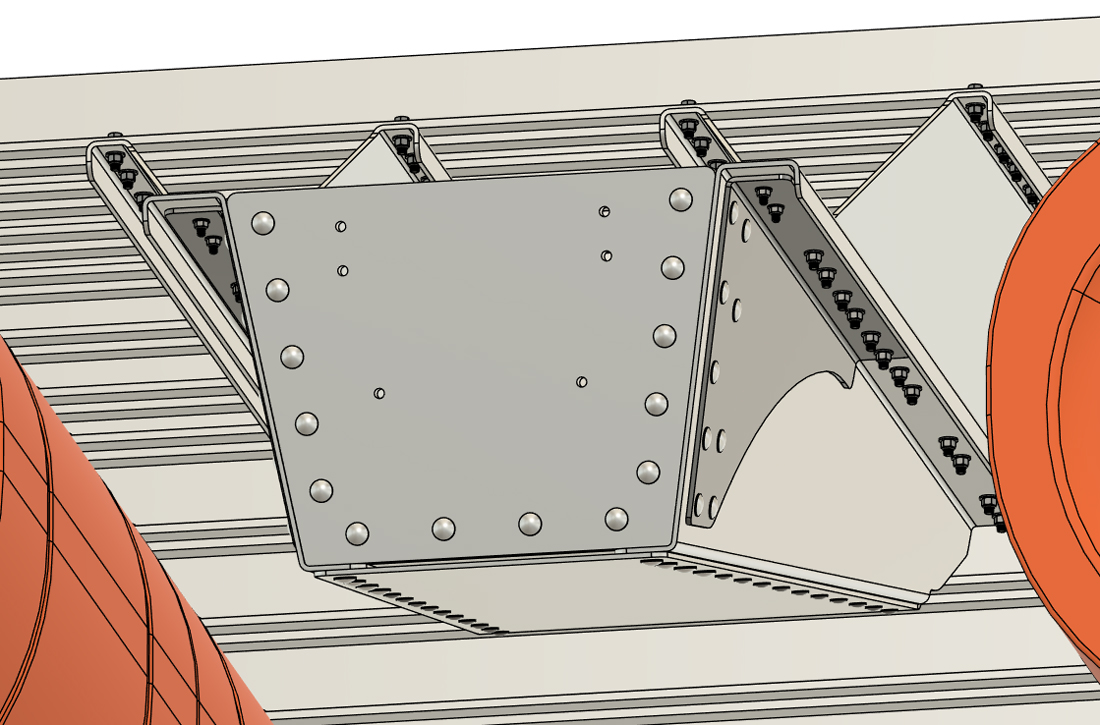

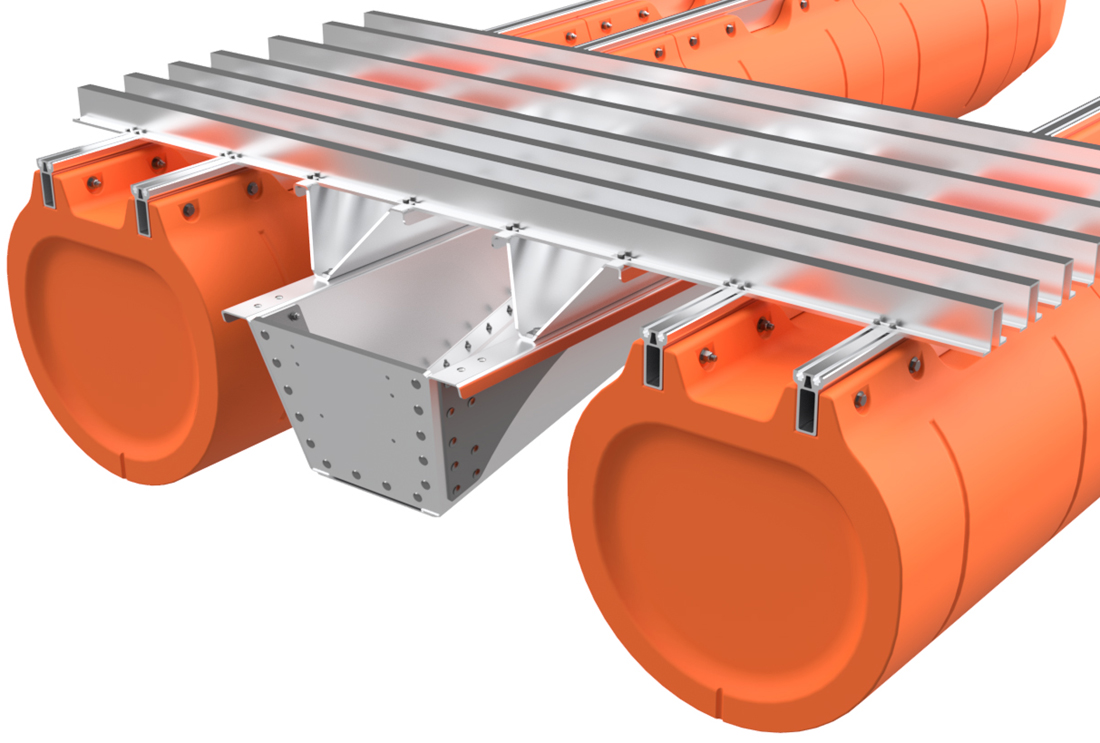

If you purchased a transom system with your barge kit, your diagram will state "Rear Set" for the rearmost 5 to 7 crossmembers. These crossmembers will have holes pre-machined for mounting your transom system and go at the rear of the boat. Please note that some dual-row pontoon systems (2 pontoon assemblies) have the "Rear Set" crossmembers placed ahead of the end of the pontoon assembly Main Beams. This is intentional in our design and helps balance the completed vessel. If you are building a triple-row barge (tri-toon) with our large transom, there will also be a "FRONT Rear Set" crossmember (see example diagram here). This crossmember both attaches to the front of your transom droip-brackets and the center pontoon assembly. If you did not purchase a transom system for your barge kit, every crossmember is identical. |

|

THIS PART OF YOUR PROJECT IS COMPLETE!

The frame and floats system for your Big Ass Pontoon Boat is now complete! Pat yourself on the back as you did a great job!

|