|

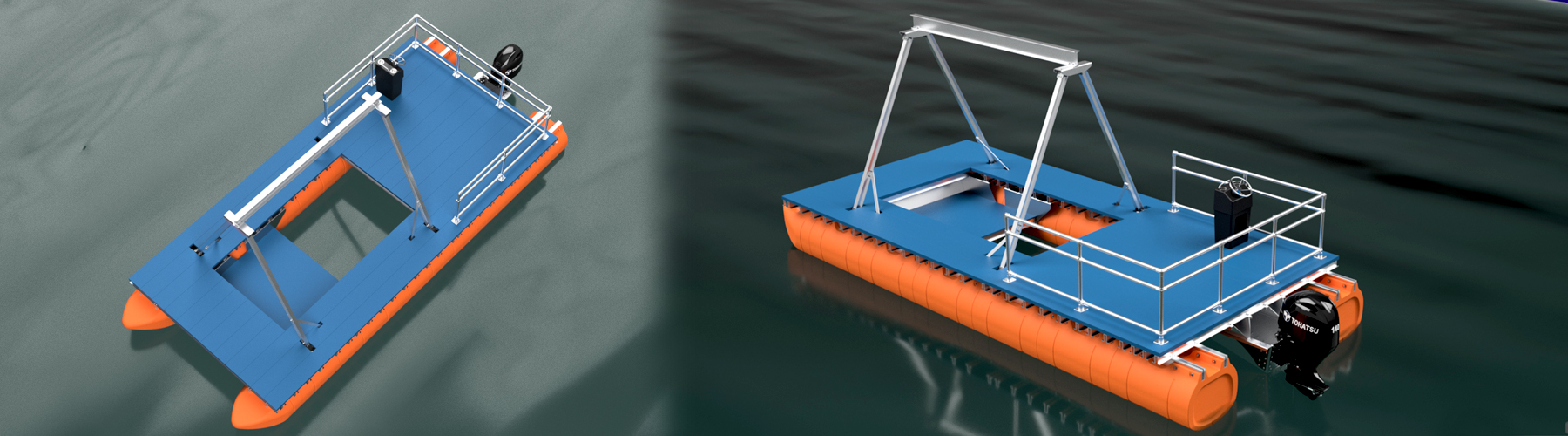

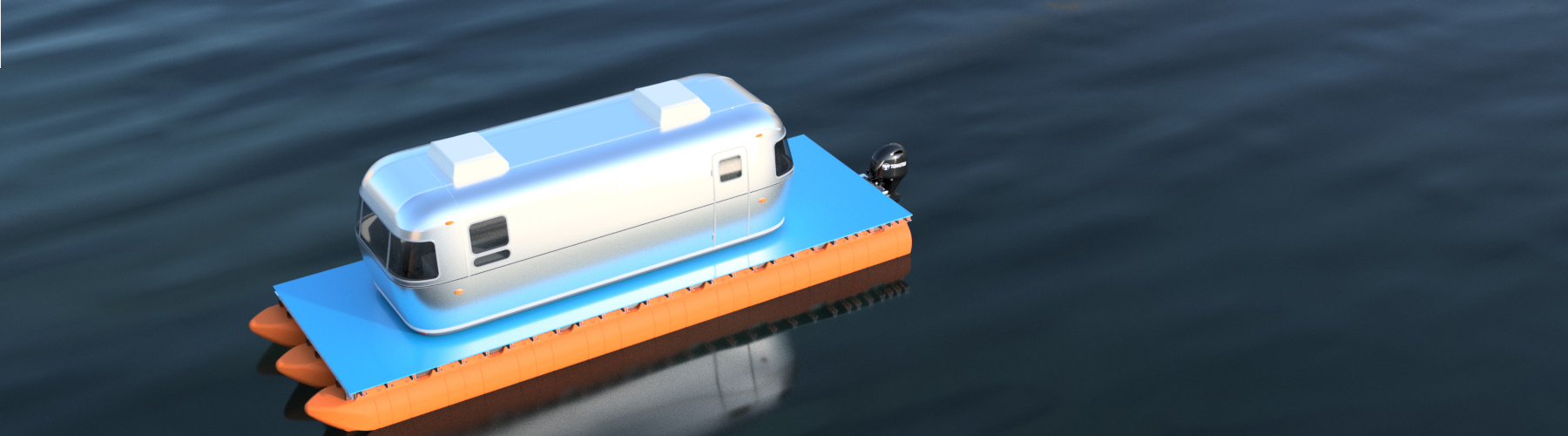

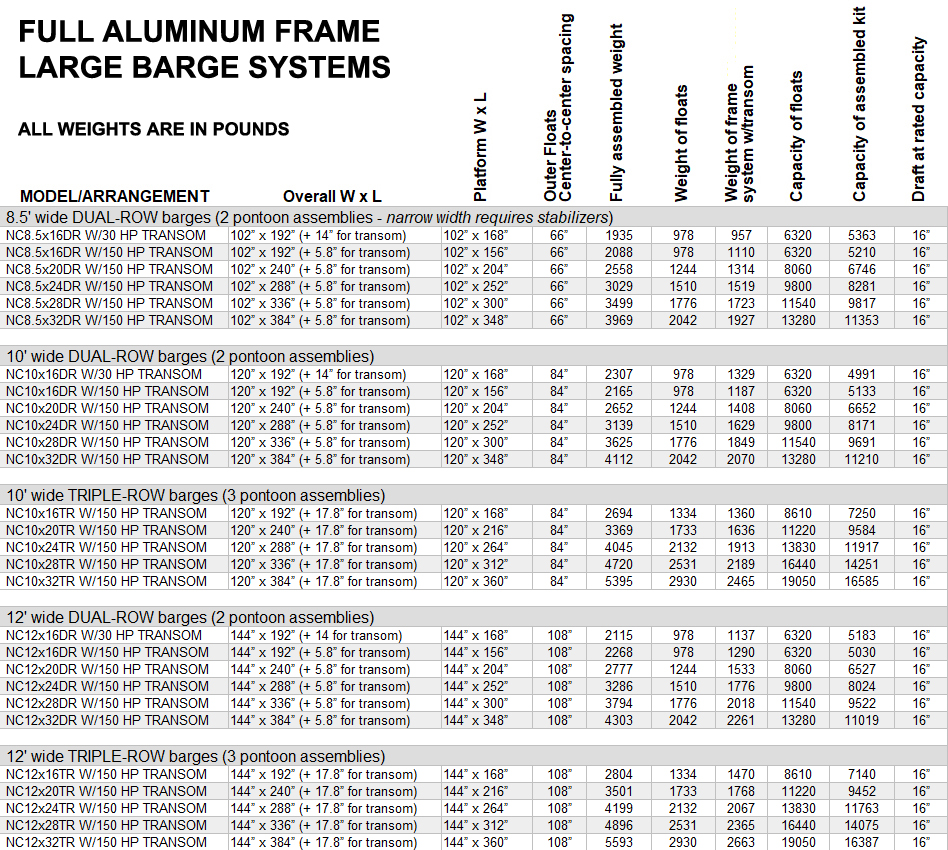

FRAME OPTION A: FULL ALUMINUM FRAME

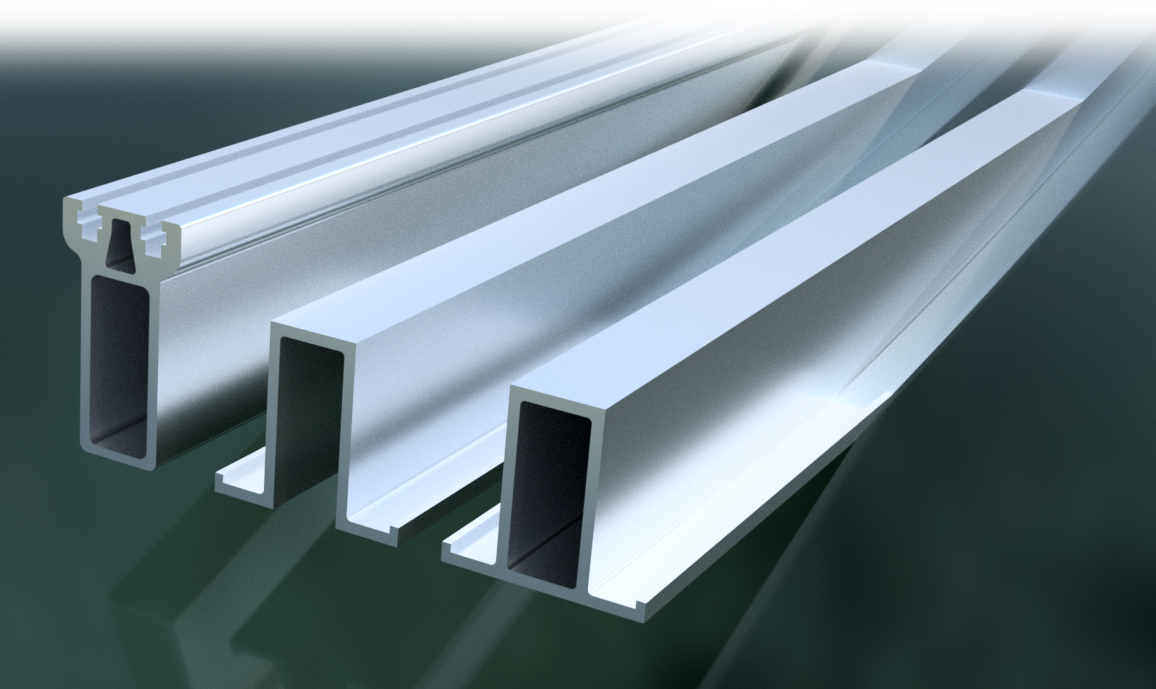

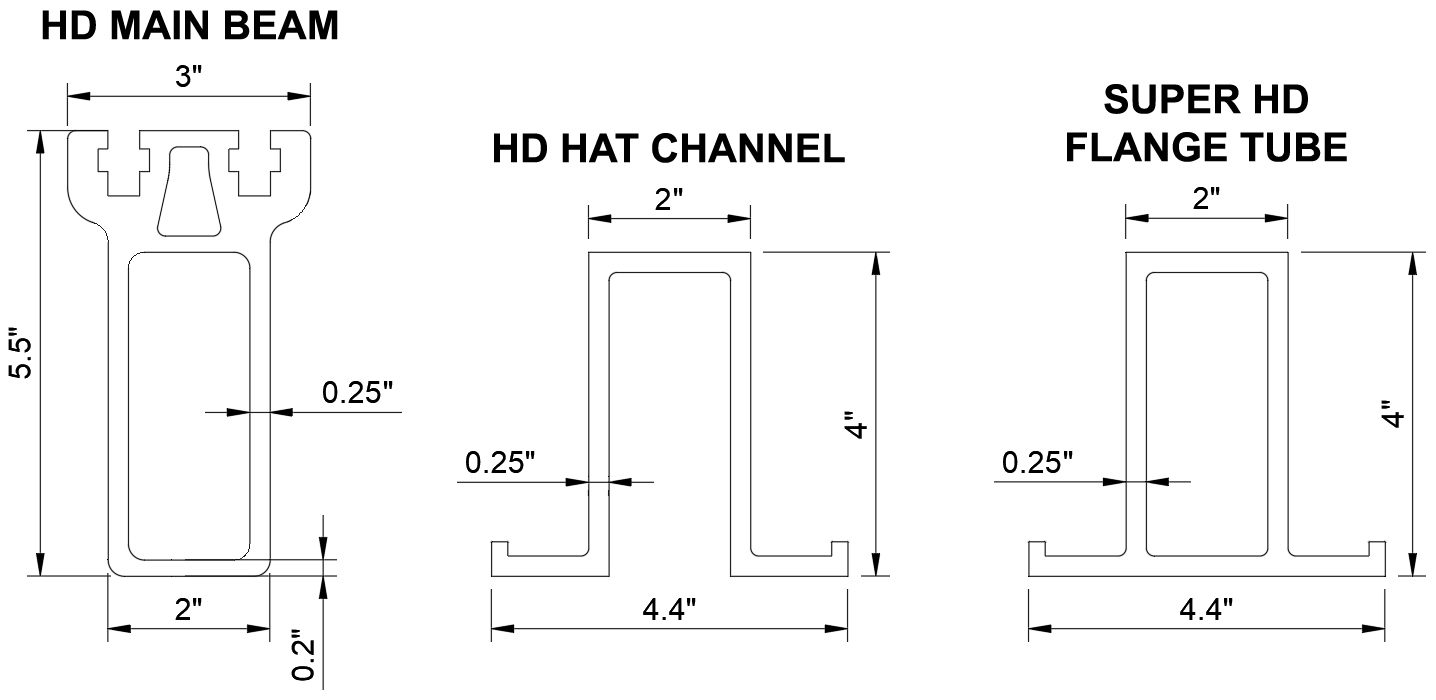

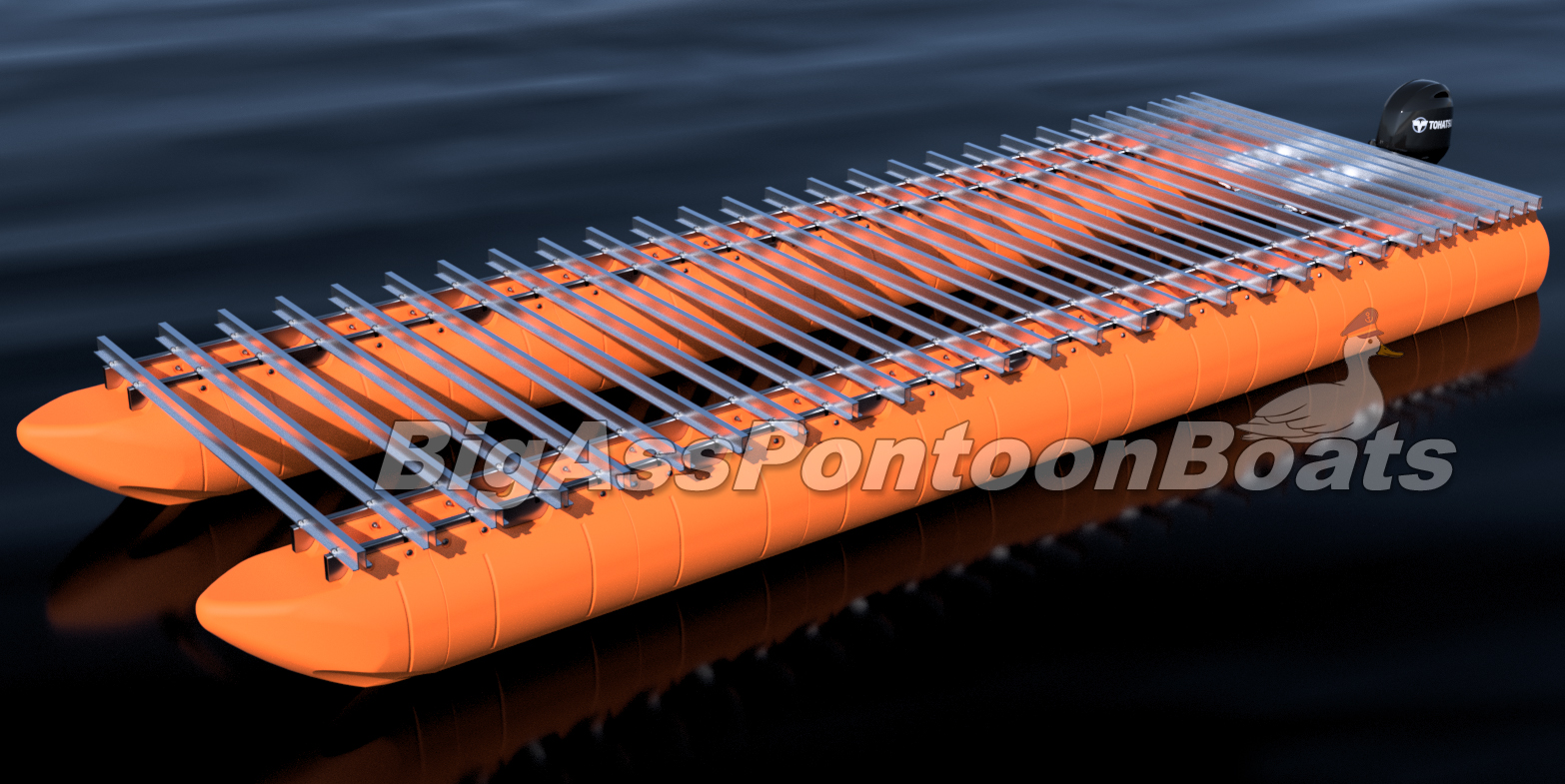

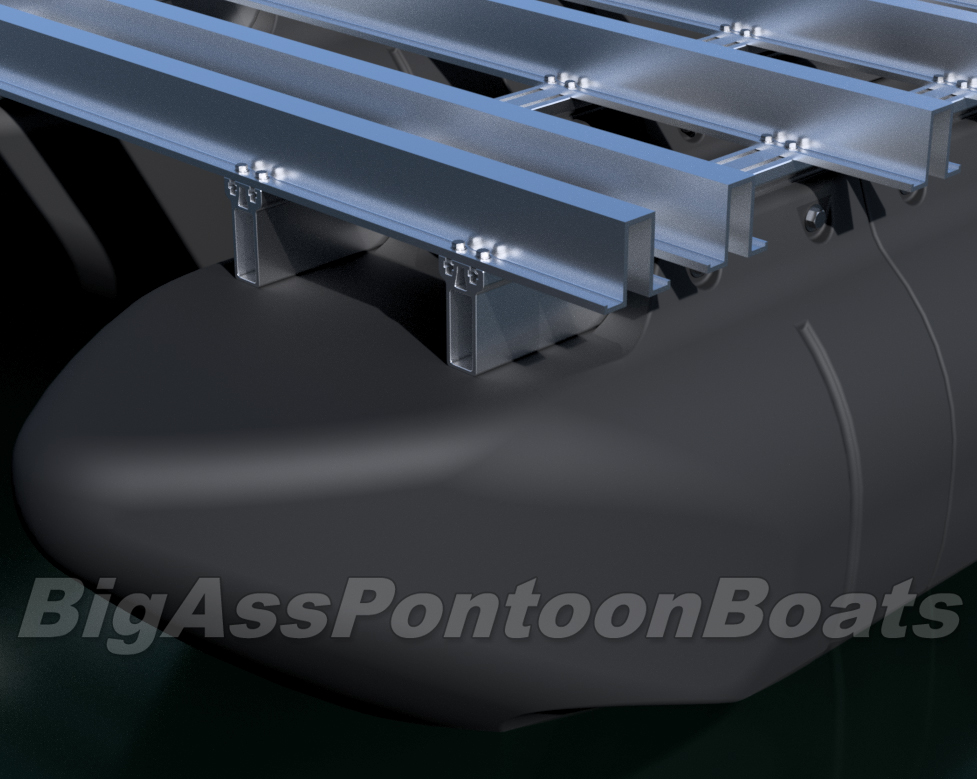

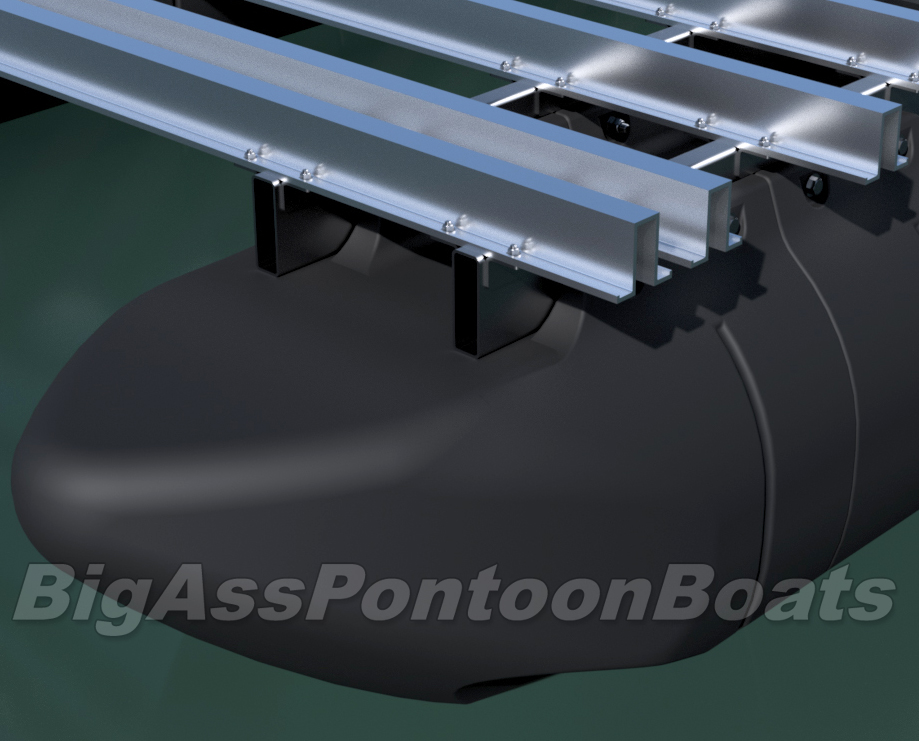

Framing option A is our full aluminum frame system. This system uses our proprietary HD Main Beam extrusion for the backbone of the pontoon assemblies and our 4" tall HD Hat Channel crossmembers. This system bolts together just like our smaller boats, but is MUCH beefier. The aluminum extrusions we use for this system are shown below.

This system has its pros, cons, and limitations. Here's a simpe run-down: PRO: Easy to assemble, fully adjustable cross-member placement, all frame members are aluminum, includes all required stainless assembly hardware. CON: Shipping for frame system can be costly if not in the New England area and going with a larger system due to the length of the Main Beams. DIMENSIONAL LIMITATIONS: Max frame length (Main Beams): 30'

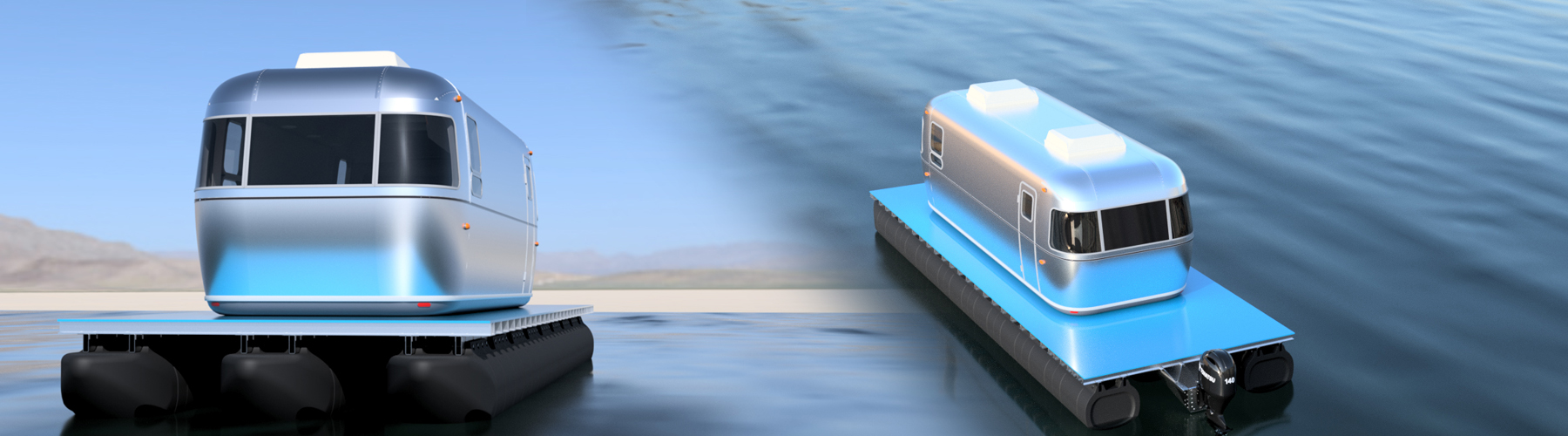

With this system, you can build boats with 2 or 3 rows of floats, dependant on your needs. We also offer 60 and 150 HP capacity transoms for this sytem. How you need your barge to be is how we'll configure your kit. Below and to the right we have provided full CAD files and current pricing for typical configurations. |

EXAMPLE BARGE SYSTEM CAD FILES:

*Engines shown installed in CAD files are not included.

|

|

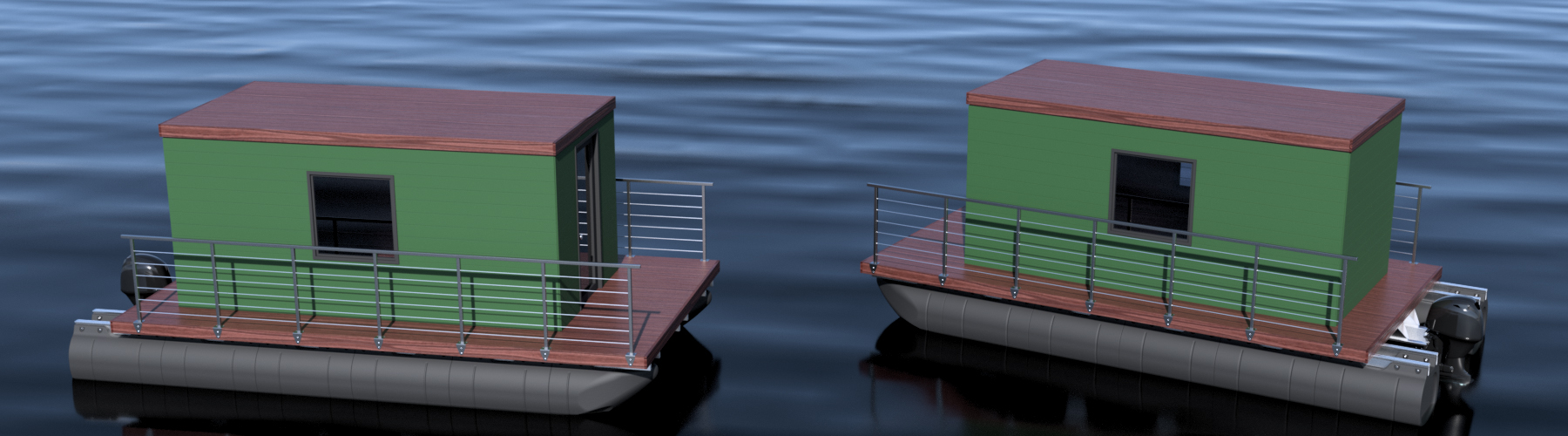

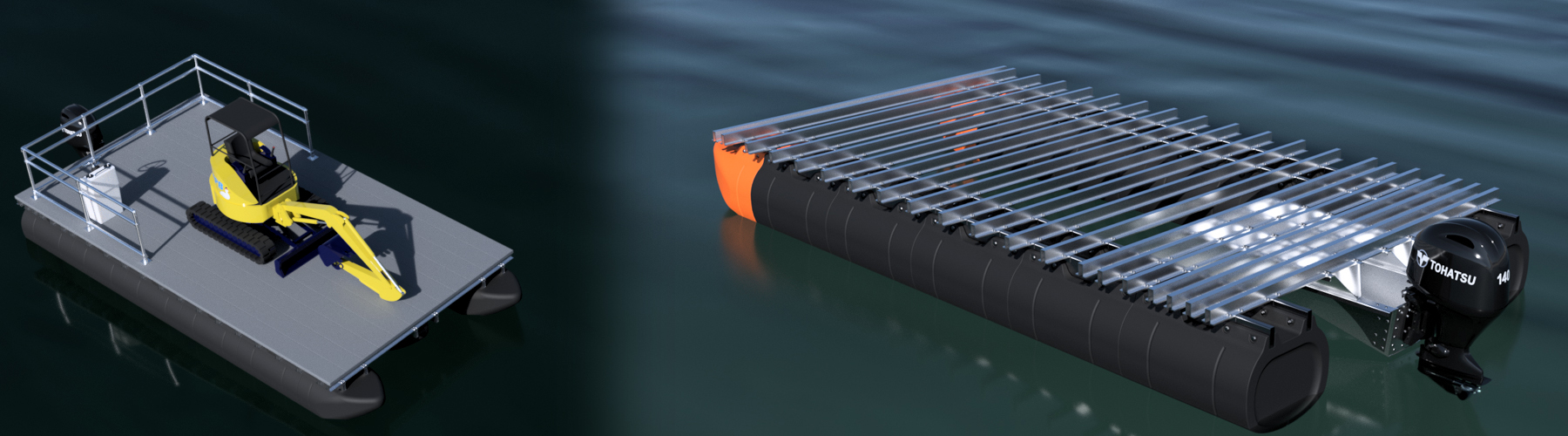

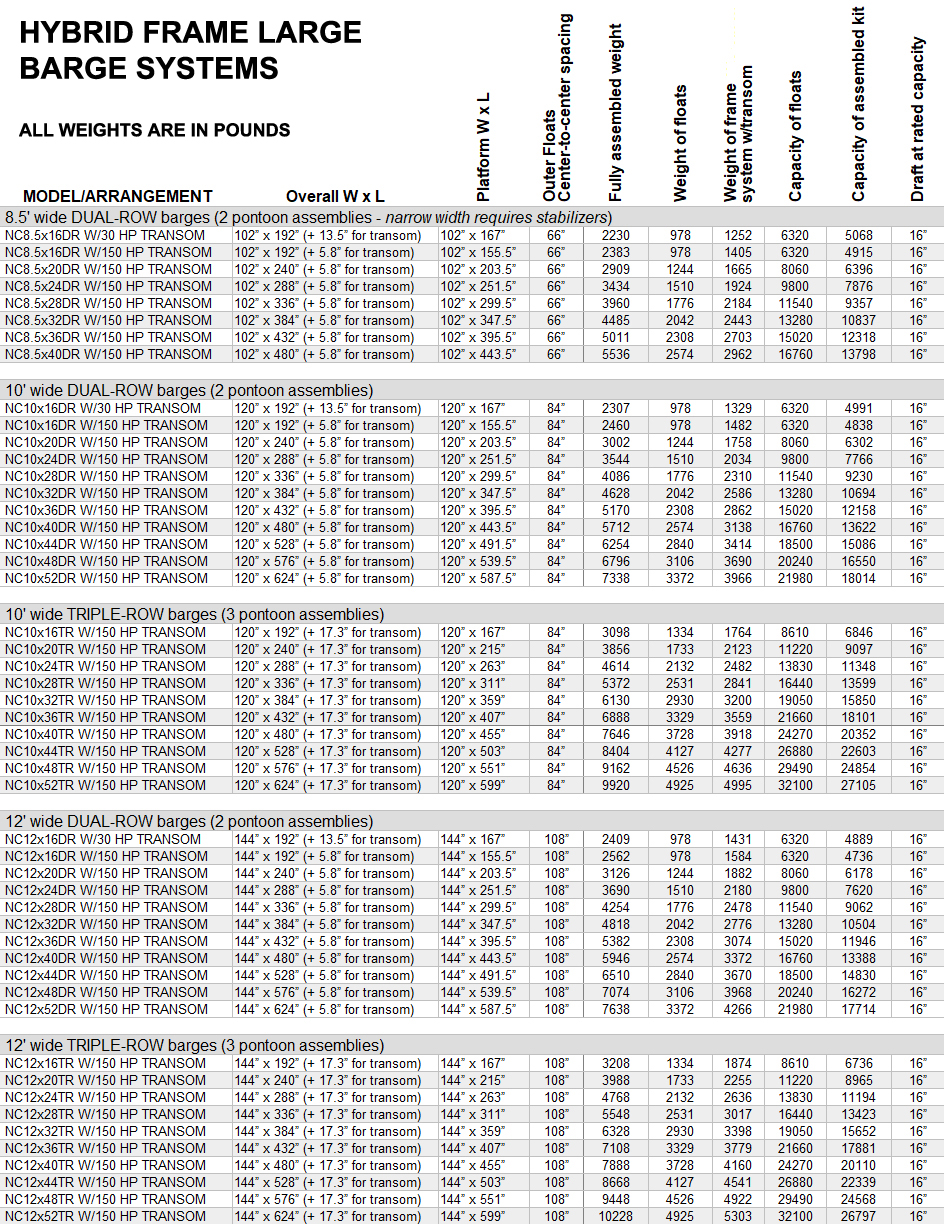

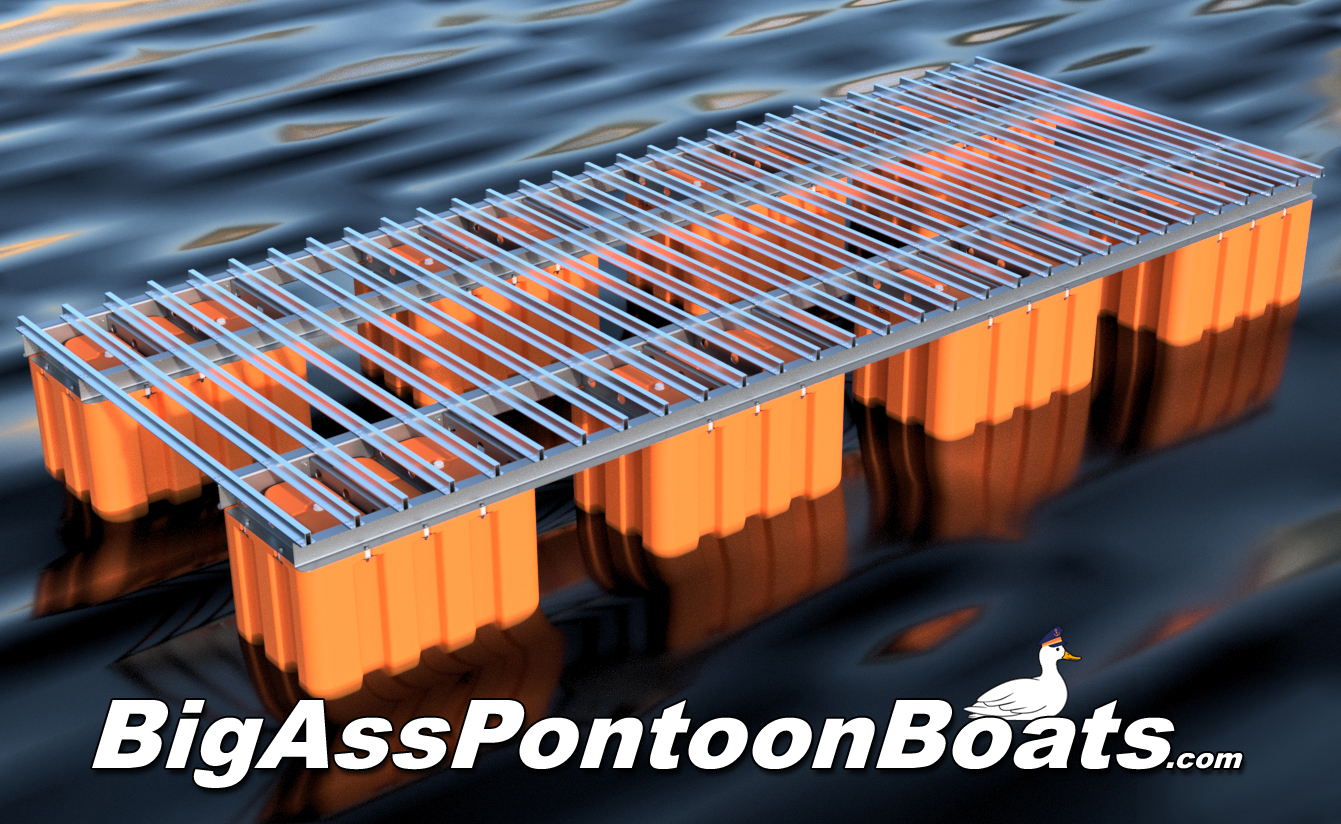

FRAME OPTION B: HYBRID FRAME SYSTEM

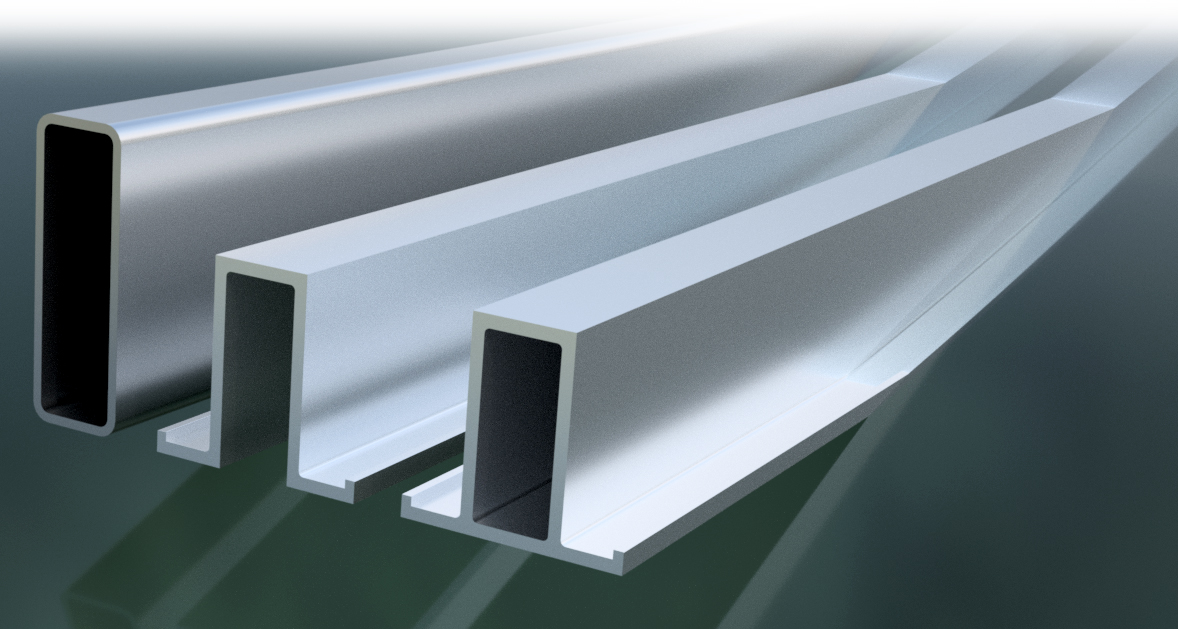

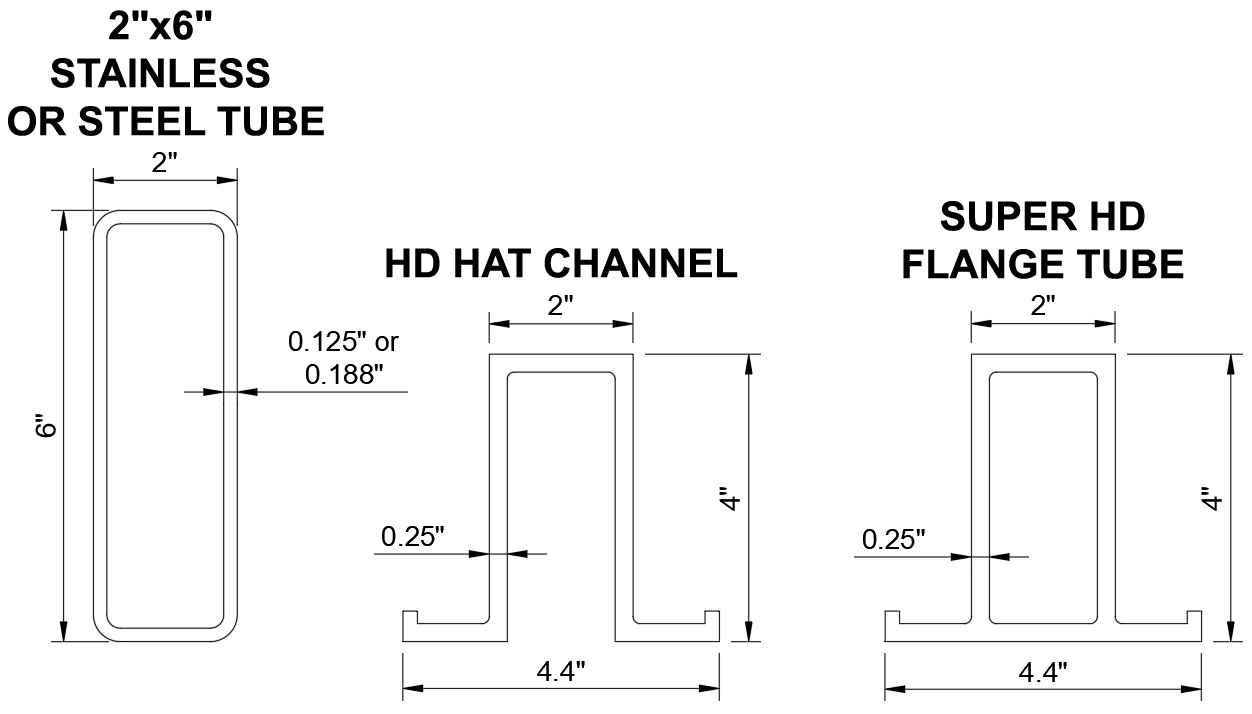

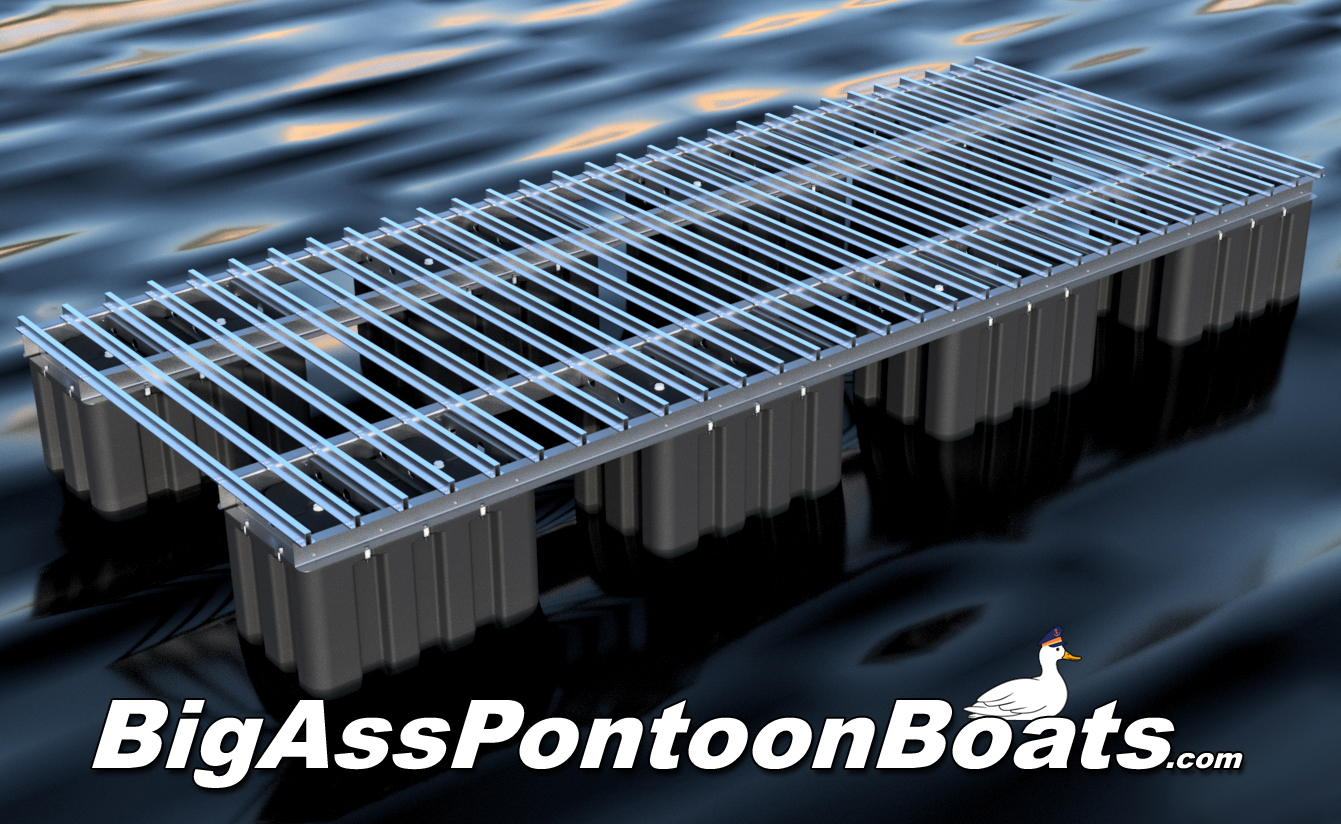

Framing option B is our hybrid stainless (or steel by spcial request) tube backbone and aluminum crossmember frame system. This system allows for longer barges than our full aluminum frame system (up to 36' with our standard configurations), but will require some expert-level welding for barges longer than 20'. This system uses laser cut 2"x6", 3/16" wall 304 stainless steel main tubes (fit into the top of the floats) and our heavy-duty 4" tall, 1/4" thick 6000 series aluminum hat channel. There are no brackets to weld in, but you do have to drill the bolt holes into the main tubes (holes come molded into the floats), and if you are building a boat longer than 20', you will have to splice the main tubes. Please be aware that the tube splicing is an expert level task, so novice welders are not to attempt this work. With this system, bolt holes and lock nut access widows come cut into the stainless main tubes. This allows for very simple assembly. Also, no local materials have to be purchased for the primary frame construction of the barge. If you've been watching our page for a bit, the prior version of our hybrid frame system required a fair amount of welding (crossmember mounting brackets had to be welded in). This system eliminates all that fussy welding and only our longer kits require a little bit of fussy welding now! This system has its pros, cons, and limitations. Here's a simpe run-down: PRO: Less shipping cost when building longer barges, frame is more resilient to extreme and abusive use, lead-times can be shorter than with frame option A CON: Longer systems require experienced welder to splice main tubes of frame, frames are heavier than full aluminum system, crossmember placement is not adjustable DIMENSIONAL LIMITATIONS: Max frame length (Main Beams): 36'

With this system, you can build boats with 2 or 3 rows of floats, dependant of your needs. We also offer 60 and 150 HP capacity transoms for this system. How you need your barge set up is how we'll configure your kit. We have provided specifications, full CAD files, and current pricing for common configurations of this system below. If you need to shave further cost out of this system, mild steel can be used in place of the stainless main tubes and we do have an option to galvanize those frame components.

|

EXAMPLE BARGE SYSTEM CAD FILES:

*Engines shown installed in CAD files are not included.

|

|

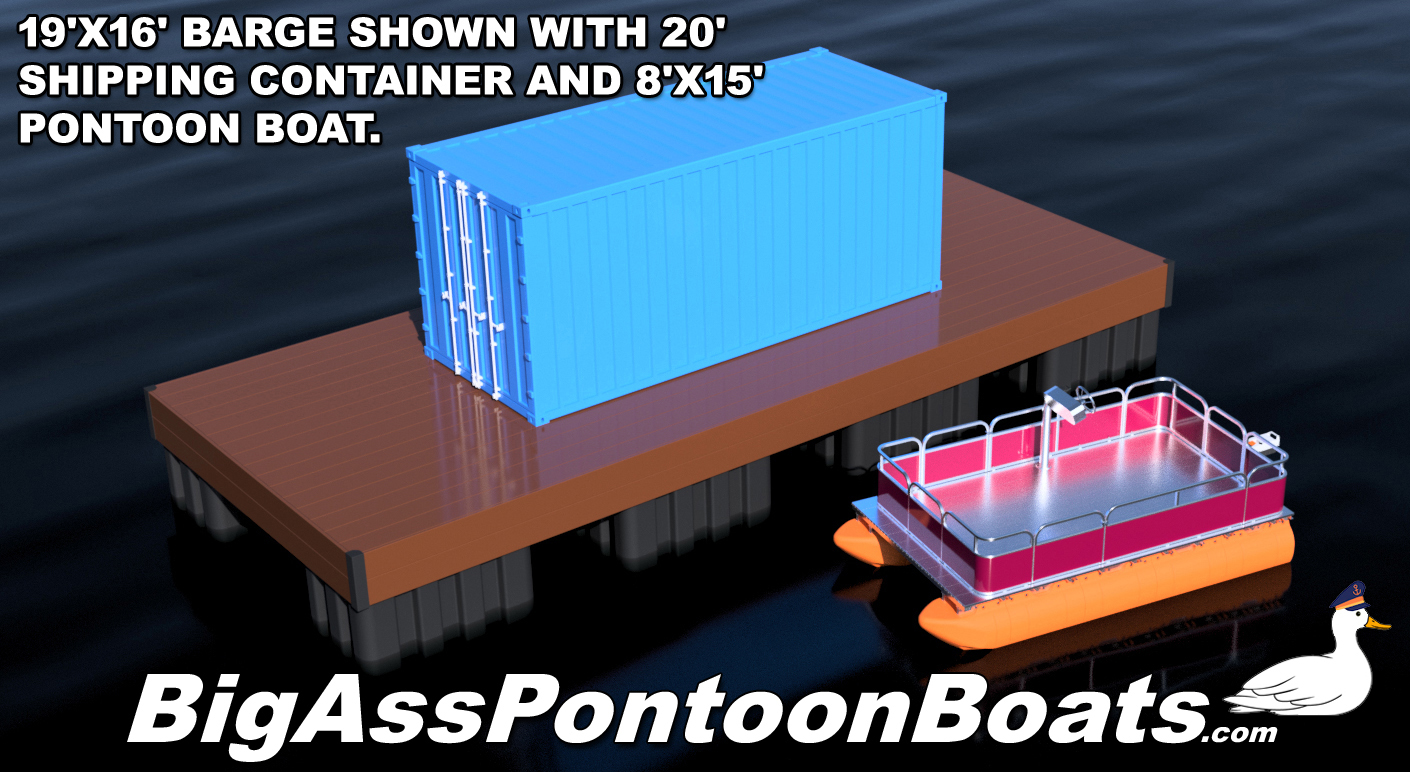

FRAME OPTION C: GIGANTIC FRAME SYSTEMS

FOR STATIONARY BARGES

If you need to build a gigantic floating platform, this concept is the way to go as it makes use of our Mammoth Dock Floats, which each take over 6800 pounds to sink! This framing system is unique as it's a departure from any of our other framing concepts. These systems can be up to 48' long (per barge module), 18' wide, and use both custom formed galvanized steel channels and our HD hat channel aluminum crossmembers. Also, these barge systems can easily be made to join multiple modules together, so if you need a 100' long barge, that's easy to accomplish. This is a completely bolt-together, all-inclusive system and is made specifically to fit the needs of each project.

As an example, we'd like to show you our 16'x39' floating barge platform. Why 39' and not 40'? At 39', the frame system can fit into a 40' shipping container and ship just about anywhere in the world. If you want to build a system like this, please check out the full CAD file listed below and contact us to talk about what it'd take to make it happen. As of 9/19/25, the current price for our example system comes to $88,404 (before freight) and the capacity of the assembled system (before any decking or accessories) at 75% submersion of the floats is approximately 35,258 pounds.

|

|

|

Army floats

Army pontoons Barge pontoons Big ass floats Big ass pontoons |

Bridge floats

Dive platform Dock floats Dredge docks Dredge floats |

Drill platforms

Dredge platforms Dredge pontoons Dredge pump floats Dredge pump pontoons |

Drilling platforms

Drill platforms Ferry floats Ferry pontoons Float house float |

Float house pontoon

Floatel floats Floatel flotation Floatel pontoons Floathouse float |

Floathouse pontoon

Floating bridge floats Drill platforms Floating bridge pontoons Floating foundation |

Floating home floats

Floating home pontoons Floating house floats Floating modular house base Floating modular platform |

Floating modular platforms

Floating pump docks Floating pump platforms Flotel floats Flotel flotation |

Flotel pontoons

Giant floats Giant modular float Giant pontoon Giant pontoons |

Giant pontoons

Houseboat floats Houseboat pontoon floats Houseboat pontoons Huge floats |

Huge pontoons

Industrial docks Industrial floats Industrial pontoons Industrial work platforms |

Marine construction floats

Military floats Military pontoons Navy floats Navy pontoons |

Pier floats

Pontoon barge system Pontoon pump floats Pontoon pump platforms Pump barge floats |

Pump barge pontoons

Pump dock floats Pump pontoons Work barge floats Work platform floats Work platform floats |

|

FREQUENTLY ASKED QUESTIONS |